Method for preparing kelp polysaccharide food

A technology for kelp polysaccharide and food, which is applied in the field of preparation of new kelp food, can solve the problems of insufficient utilization of kelp active ingredients, poor taste, difficult absorption of alginate, etc., and achieves prevention of large neck disease, good elasticity, The effect of preventing high blood pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

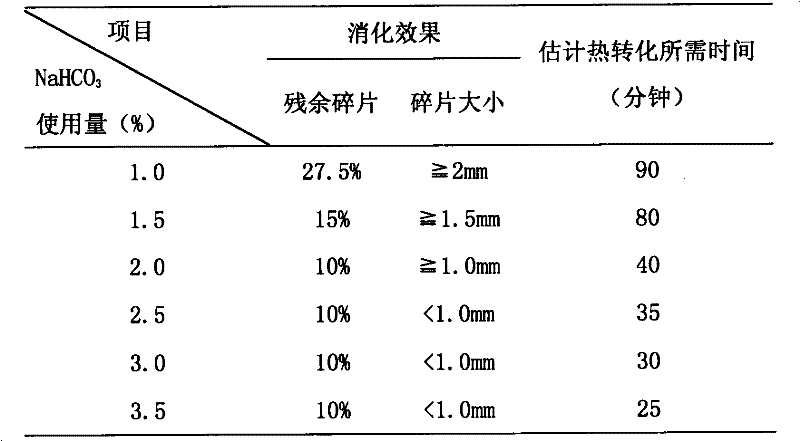

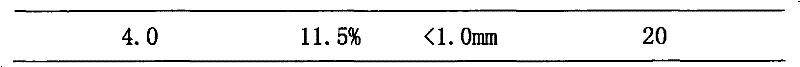

[0027] Use 100°C hot water to kill 1000g of fresh kelp, cool it with cold water, take it out, shred or mince it with a shredder or a mincer, put it into a transformation pot, and add 30g of NaHCO 3, heated and transformed at a temperature of 70°C for 80 minutes while stirring, and the initially transformed kelp paste was added to a colloid mill, and was ground and transformed twice at a speed of 5500rpm while hot to obtain a laminarin dietary fiber paste, which was taken out and added to Mixing in 3000g of flour, dough conditioning, rolling and forming, cutting into strips, shaping, steaming, drying, and packaging to obtain finished products. The composition of the sea-tangle raw material and the laminarin dietary fiber surface that embodiment 1 makes has been detected, and test result is as shown in table 2 below:

[0028] Table 2 Composition and content of laminarin dietary fiber noodles

[0029]

[0030]

Embodiment 2

[0032] Clean 1000g of fresh kelp with hot seawater at 70°C, cool it with cold water, rinse it, take it out, shred or mince it with a shredder or a mincer, put it into a transformation pot, and add 25g of NaHCO 3 , heated and transformed at 95°C for 90 minutes while stirring, and the initially transformed kelp paste was added to the colloid mill, and ground and transformed 3 times at 70°C with a rotation speed of 2000rpm to obtain laminarin dietary fiber paste, which was taken out and added to 2.5Kg Rice noodles are mixed, adjusted, rolled and formed, cut into strips, shaped, steamed, dried, and packaged to obtain finished products.

Embodiment 3

[0034] Take out 1000g washed fresh kelp with hot water at 80°C, shred or mince it with a shredder or grinder, put it into a transformation pot, and add 35g of NaHCO 3 , heating and transforming while stirring for 70 minutes, the kelp paste obtained for initial transformation was added in a colloid mill, ground and transformed 1 time while hot with a rotating speed of 2000rpm, and the laminarin dietary fiber paste was obtained, and 5Kg flour was added and an appropriate amount of yeast was mixed, The noodles are adjusted, fermented, cut and placed in an oven to make bread, and the finished product is packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com