Solvent-free epoxy heavy-duty anticorrosive coating for automatic spraying for online repairing of petroleum pipelines

An automatic spraying, oil pipeline technology, applied in anti-corrosion coatings, epoxy resin coatings, polyamide coatings, etc., can solve the problems of explosion, short pot life, surface dry and hard dry time can not meet the requirements, etc., to achieve low viscosity , suitable period of validity, the effect of reducing investment and pipeline transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiment of the present invention sees the following table:

[0025] Component A paint raw material name

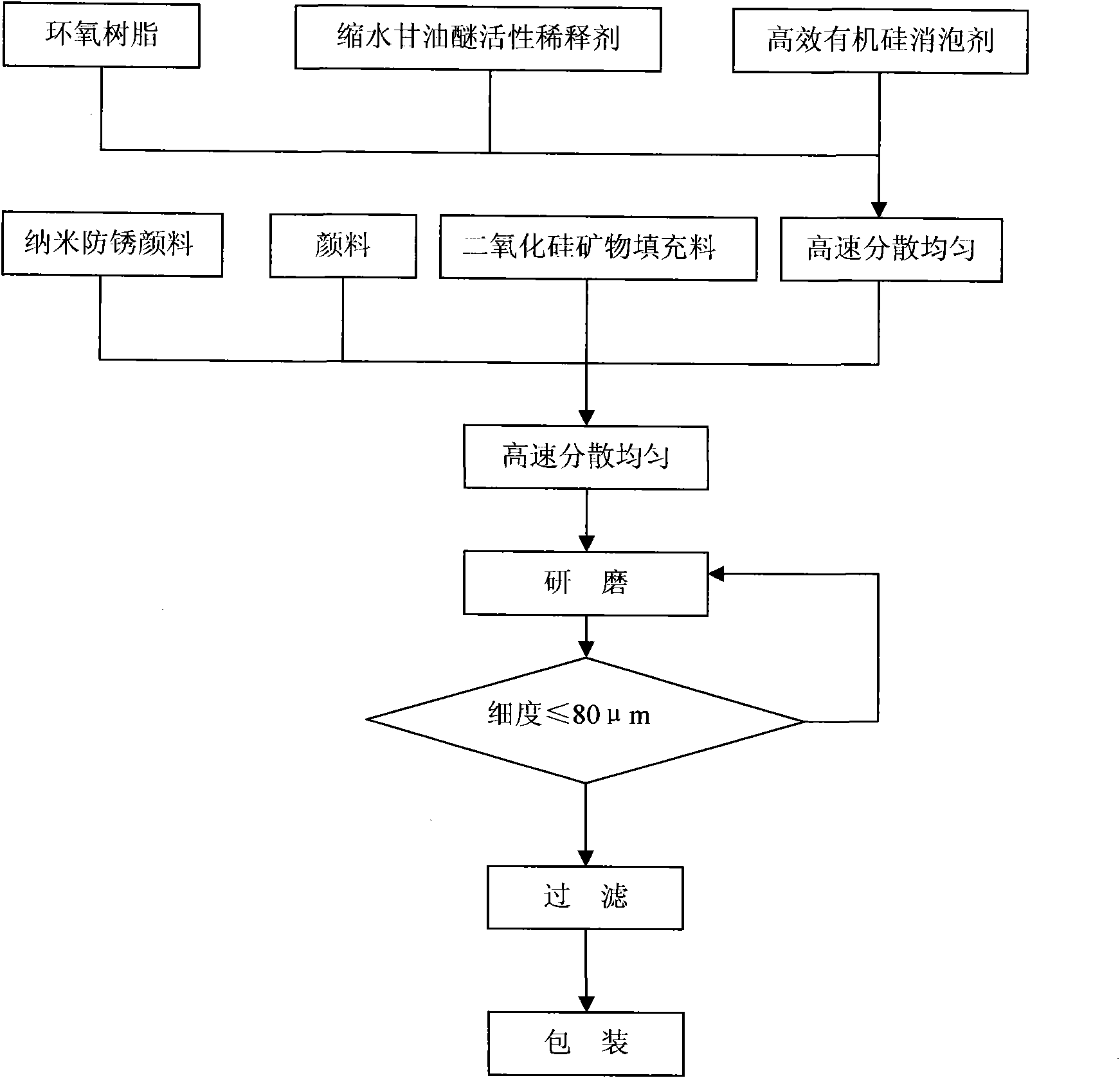

[0026] Take the corresponding parts of epoxy resin, glycidyl ether reactive diluent and high-efficiency silicone defoamer in Examples 1, 2 and 3, and add them to the stainless steel cylinder in sequence. The corresponding part of antirust pigment, the corresponding part of silica mineral filler, and the corresponding part of coloring pigment, after being uniformly dispersed at high speed, grind with a three-roll mill, and the material can be discharged when the fineness reaches ≤80 μm, and filtered with an 80-mesh filter Then pack it.

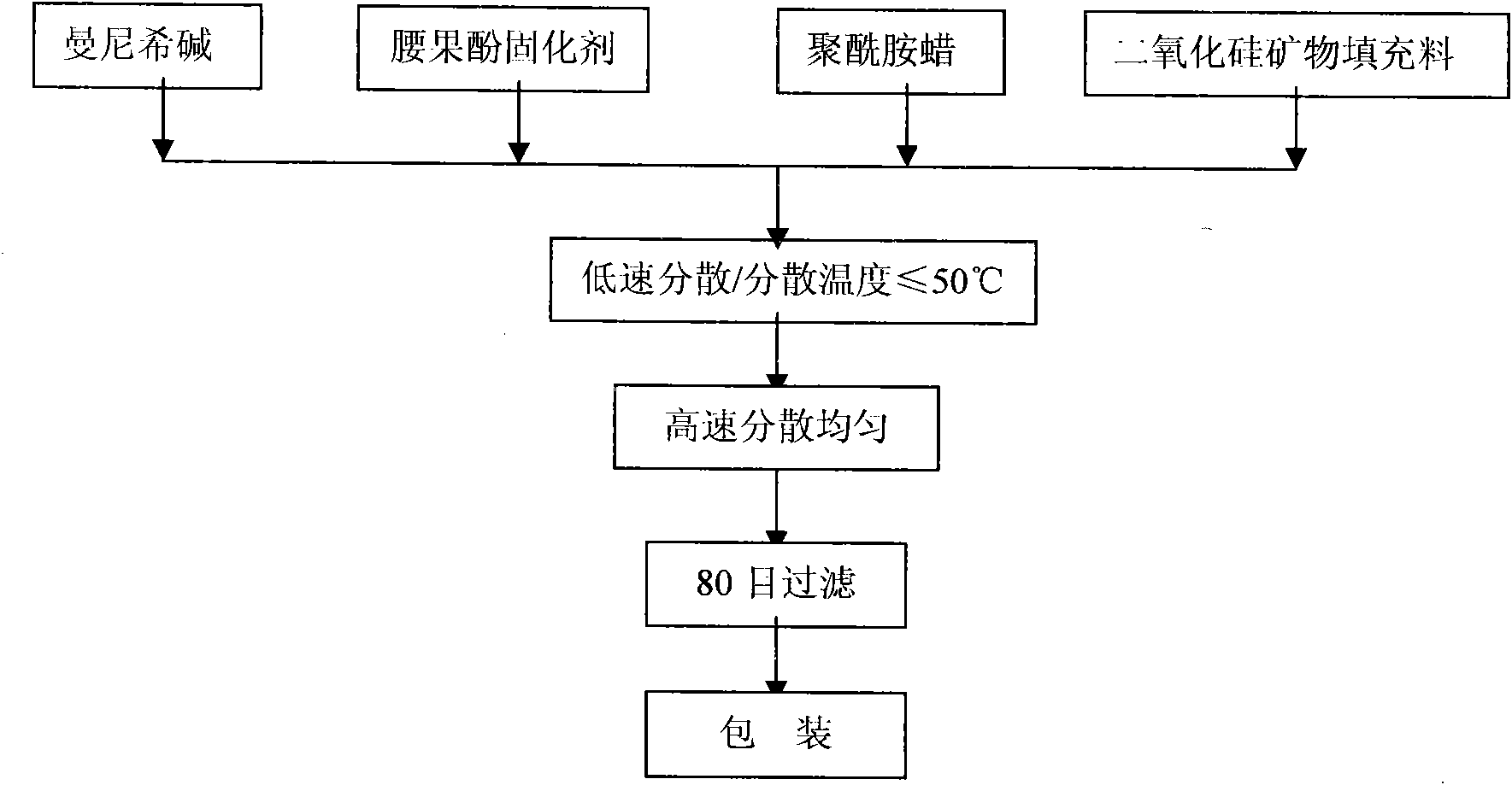

[0027] Take the corresponding parts of Mannich base, the corresponding parts of cardanol curing agent, the corresponding parts of polyamide wax, and the corresponding parts of silica mineral filler in Examples 4, 5, and 6, and add them to the stainless steel cylinder in turn, disperse at a low speed for 25min, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com