Preparation method of biological active glass/chitosan composite porous support material

A bioactive glass and porous scaffold technology, applied in the field of biomedical materials, can solve the problems of insufficient mechanical strength of porous scaffold materials, no industrial application, and difficulty in meeting the requirements of providing support for tissue defects, so as to facilitate cell adhesion and proliferation, The process parameters are easy to control and the effect of the appropriate pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

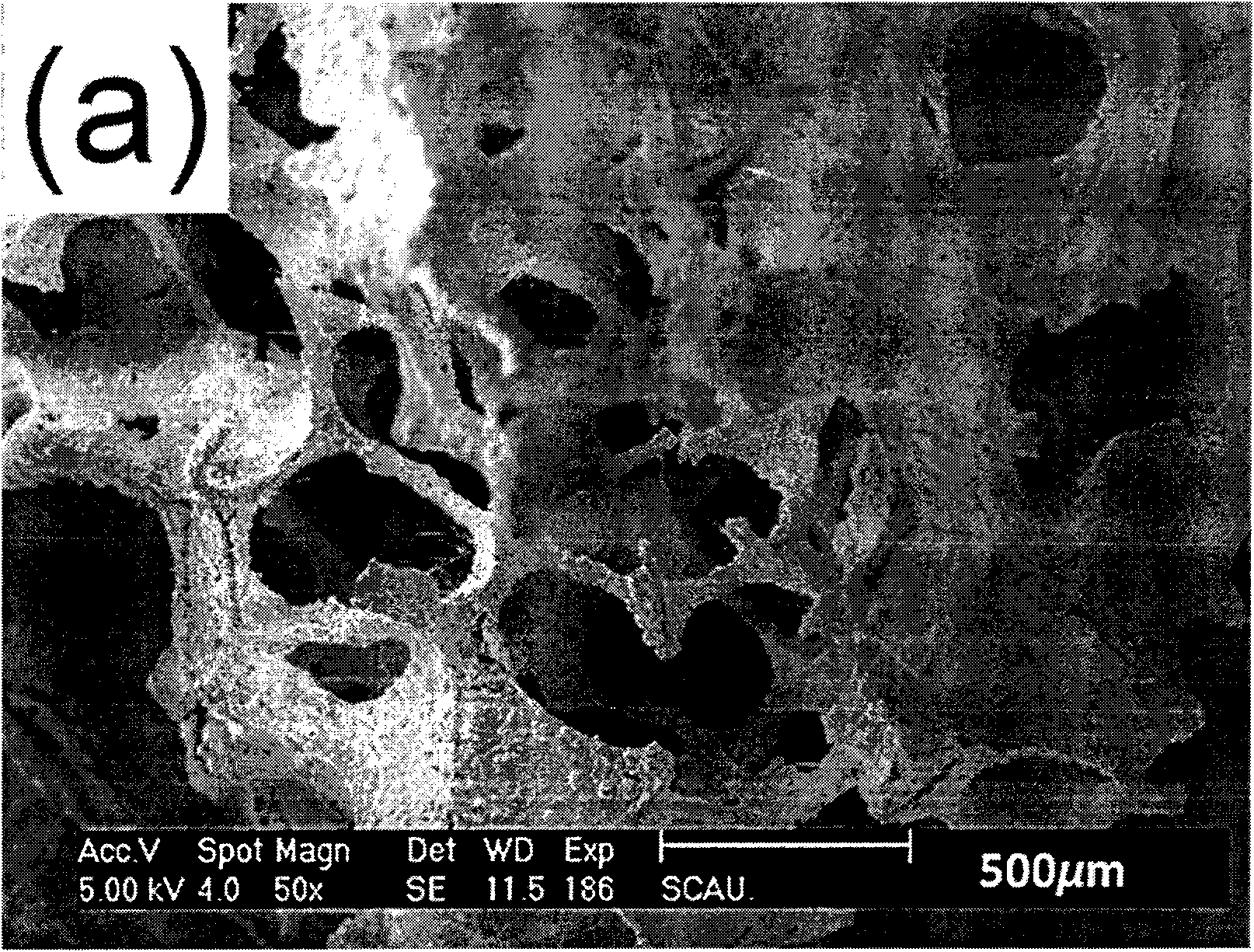

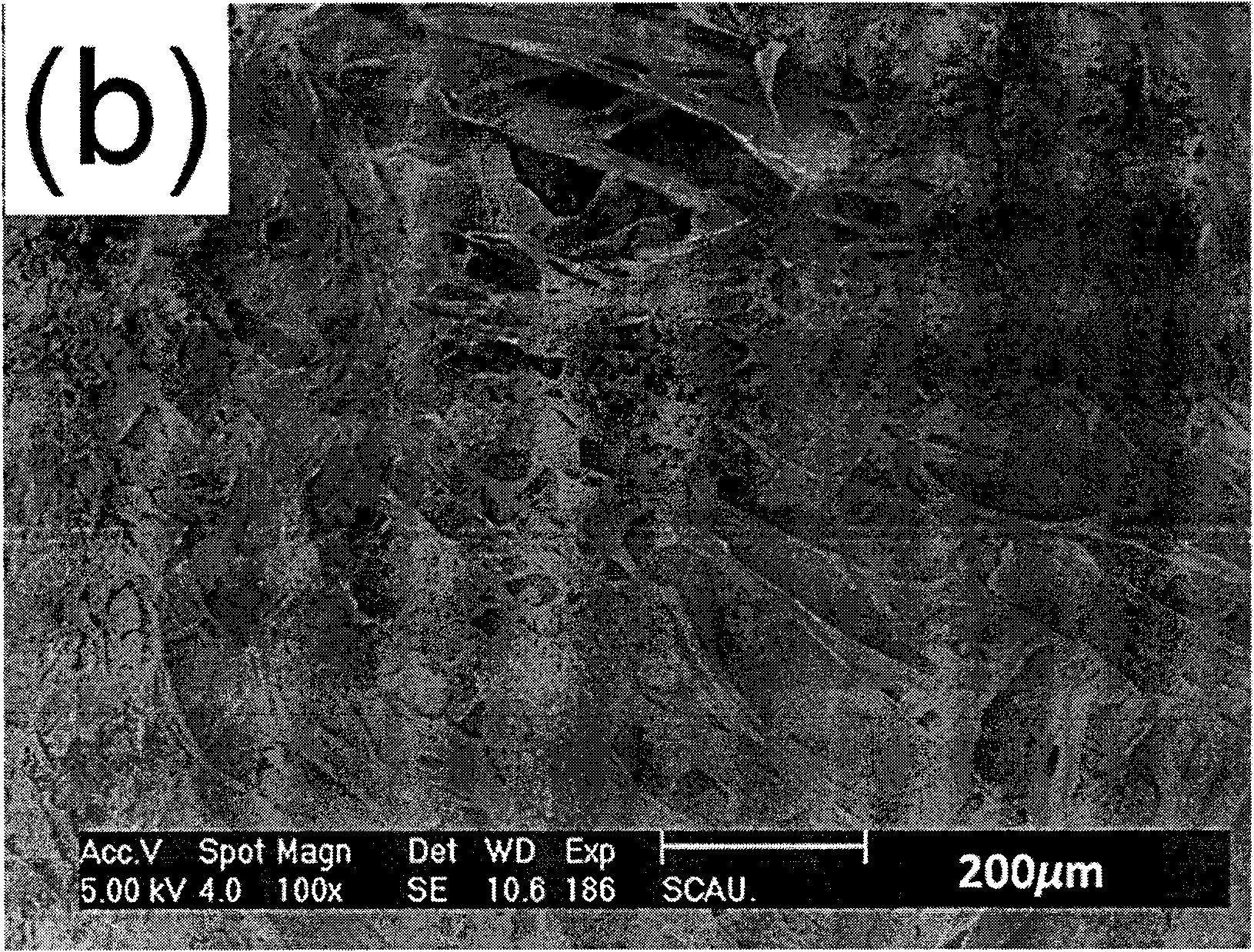

[0028] A method for preparing a bioactive glass / chitosan composite porous scaffold material uses a perfusion method to compound chitosan and a sol-gel bioglass porous scaffold material prepared by a foam impregnation method, including the following steps and process conditions:

[0029] Step 1: Preparation of pure bioactive glass scaffold materials by foam impregnation method

[0030] (1) CaO-P prepared by sol-gel method 2 o 5 -SiO 2 It is a bioactive glass ball milled and sieved, and the bioactive glass powder with a particle size not greater than 15 μm is taken for use;

[0031] (2) Add 3 parts by weight of polyvinyl alcohol to 100 parts by weight of deionized water as a binder, heat in a constant temperature water bath at 80°C, and stir vigorously for 2 hours. After the binder is completely dissolved, add 50 parts by weight The sieved bioactive glass powder with a particle size not greater than 15 μm was vigorously stirred for 2 hours to make a slurry, and the obtained s...

Embodiment 2

[0040] A method for preparing a bioactive glass / chitosan composite porous scaffold material uses a perfusion method to compound chitosan and a sol-gel bioglass porous scaffold material prepared by a foam impregnation method, including the following steps and process conditions:

[0041] Step 1: Preparation of pure bioactive glass scaffold materials by foam impregnation method

[0042] (1) CaO-P prepared by sol-gel method 2 o 5 -SiO 2 It is a bioactive glass ball milled and sieved, and the bioactive glass powder with a particle size not greater than 15 μm is taken for use;

[0043] (2) Add 5 parts by weight of polyvinyl alcohol to 100 parts by weight of deionized water as a binder, heat in a constant temperature water bath at 70°C, and stir vigorously for 1 hour. After the binder is completely dissolved, add 30 parts by weight The sieved bioactive glass powder whose particle size is not greater than 15 μm is vigorously stirred for 1 hour to make a slurry, and the obtained slur...

Embodiment 3

[0051] A method for preparing a bioactive glass / chitosan composite porous scaffold material uses a perfusion method to compound chitosan and a sol-gel bioglass porous scaffold material prepared by a foam impregnation method, including the following steps and process conditions:

[0052] Step 1: Preparation of pure bioactive glass scaffold materials by foam impregnation method

[0053] (1) CaO-P prepared by sol-gel method 2 o 5 -SiO 2 It is a bioactive glass ball milled and sieved, and the bioactive glass powder with a particle size not greater than 15 μm is taken for use;

[0054] (2) Add 4 parts by weight of carboxymethyl cellulose or starch to 100 parts by weight of deionized water as a binder, heat in a constant temperature water bath at 90°C, and stir vigorously for 1.5 hours until the binder is completely dissolved , adding 40 parts by weight of sieved bioactive glass powder with a particle size not greater than 15 μm, stirring vigorously for 2 hours to make a slurry, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

| Large hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com