Preparing method of lowering residual monomer content of ultra high molecular weight anion-type polyacrylamide

A polyacrylamide, ultra-high molecular weight technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of high toxicity, high content of acrylamide monomers, and inability to meet the requirements of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

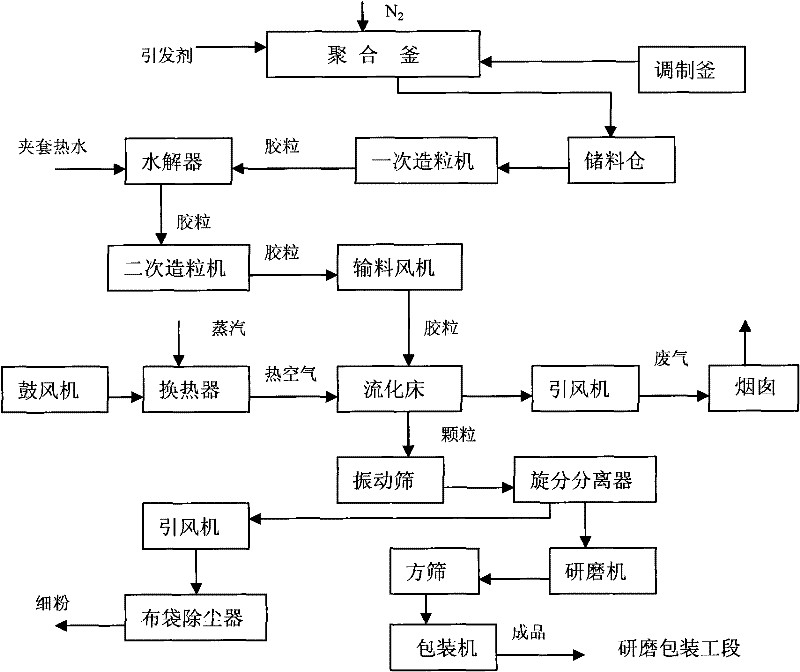

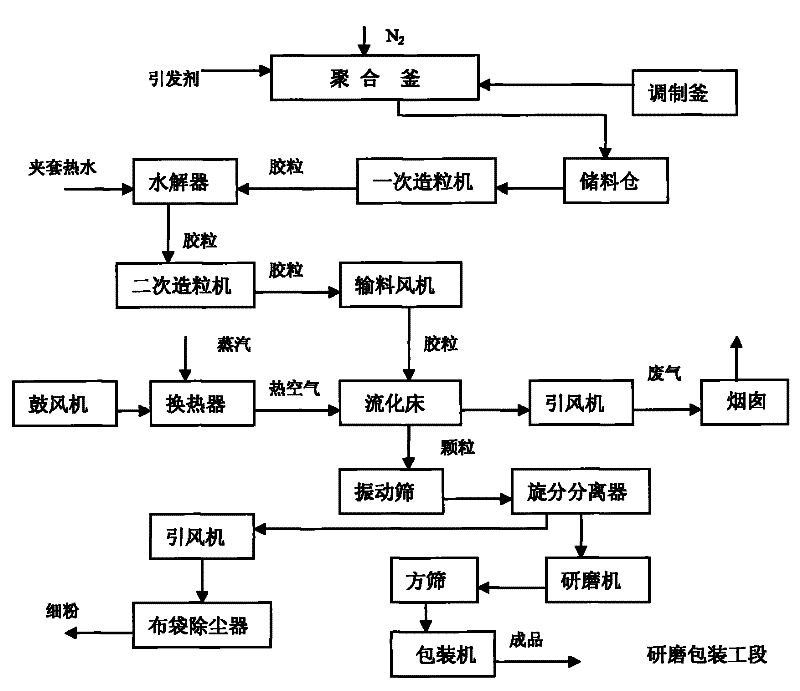

Method used

Image

Examples

Embodiment 1

[0013] Example 1: Add 0.9t of acrylamide, 4.1t of desalted water, and 20kg of urea into the preparation kettle. After vigorous stirring, the jacket cools down to 0°C with refrigerant water, which is transported to the polymerization kettle through a delivery pump. Nitrogen for 20 minutes, add potassium persulfate, sodium bisulfite, urea, and water-soluble azo compounds, continue to pass nitrogen for 40 minutes, hold pressure for polymerization, until the temperature does not rise, the polymerization reaction is completed, unload to the storage box for a granulation , add 200kg caustic soda to the hydrolyzer for granulation, and react in the hydrolyzer. After the jacket is heated to 75°C, place it for 1 hour for secondary granulation, transport it to the fluidized bed and pass it into hot air to dry to a solid content of about 90%, and transport to the grinding packaging system. Product quality: solid content ≥ 89%, apparent viscosity 15.0mPa.s (salinity 20000mg / L, temperature ...

Embodiment 2

[0014] Example 2: Add 0.8t of acrylamide, 4.1t of desalted water, 0.1tAMPS, and 5kg of urea into the preparation kettle. After vigorous stirring, the jacket cools down to 0°C with refrigerant water, and transports it to the polymerization kettle through a delivery pump. Pass through high-purity nitrogen for 20 minutes, add potassium persulfate, sodium bisulfite, sodium formate, and water-soluble azo compounds, continue to pass nitrogen for 40 minutes, hold pressure for polymerization, and complete the polymerization reaction until the temperature does not rise. For primary granulation, add 180kg of caustic soda to the hydrolyzer for reaction in the hydrolyzer. After the jacket is heated to 80°C, place it for 1 hour for secondary granulation, transport it to the fluidized bed and dry it with hot air to a solid content of 90%. Left and right, transported to the grinding and packaging system. Product quality: solid content ≥ 89%, apparent viscosity 14.0mPa.s (salinity 32000mg / L, ...

Embodiment 3

[0015] Example 3: Add 0.8 t of acrylamide, 4.1 t of desalted water, 0.2 t of acrylic acid, and 5 kg of urea into the preparation tank. After vigorous stirring, cool the jacket to 0°C with refrigerant water, and then transport it to the polymerization tank through a delivery pump. , pass through high-purity nitrogen for 20 minutes, add potassium persulfate, sodium bisulfite, sodium formate, and water-soluble azo compounds, continue to pass nitrogen for 40 minutes, hold pressure for polymerization, until the temperature does not rise, the polymerization reaction is completed, and unload to the storage box Carry out a granulation, add 180kg caustic soda to the hydrolyzer, and carry out the reaction in the hydrolyzer. After the jacket is heated to 80°C, place it for 2 hours for the second granulation, transport it to the fluidized bed and pass it into hot air to dry to a solid content of 90 % or so, transported to the grinding packaging system. Product quality: solid content ≥ 89%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com