Organic silicon modified acrylic ester aqueous wood lacquer latex and synthesizing method thereof

A water-based wood paint, acrylic technology, applied in latex paint, coating and other directions, can solve the problems of flexibility, poor wear resistance, poor scratch resistance, etc., to achieve the effect of improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

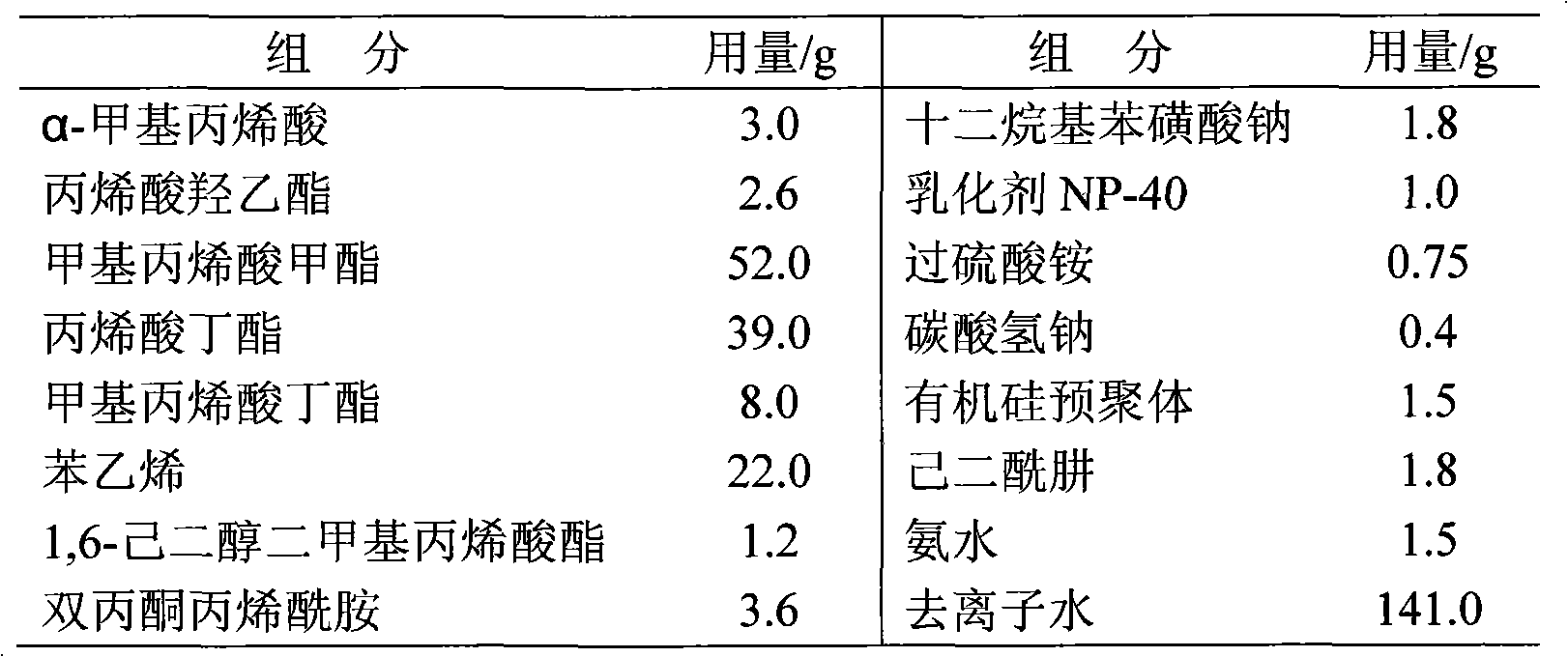

[0039] The raw material formula of silicone modified acrylate water-based wood paint emulsion is shown in Table 1:

[0040] Table 1 Silicone-modified acrylate emulsion formula

[0041]

[0042] Its synthetic method is:

[0043] ① Preparation of nuclear emulsion: 0.8g of sodium dodecylbenzenesulfonate, NP-400.4g, 15g of deionized water, 22g of methyl methacrylate, 13g of styrene, 8g of butyl methacrylate, 1 Add 0.6 g of 6-hexanediol dimethacrylate into the pre-emulsification tank successively, stir for 15 min to obtain the pre-emulsion of the nuclear monomer; add 0.2 g of sodium dodecylbenzenesulfonate, carbonic acid Sodium hydrogen 0.4g, deionized water 46g, pre-emulsion 8g of nuclear monomer, add 15g ammonium persulfate aqueous solution (ammonium persulfate 0.75g is dissolved in 35g deionized water) when warming up to 50 ℃, and continue to heat up to 82 ±1°C, add the remaining nuclear monomer pre-emulsion and the remaining ammonium persulfate aqueous solution dropwise af...

Embodiment 2

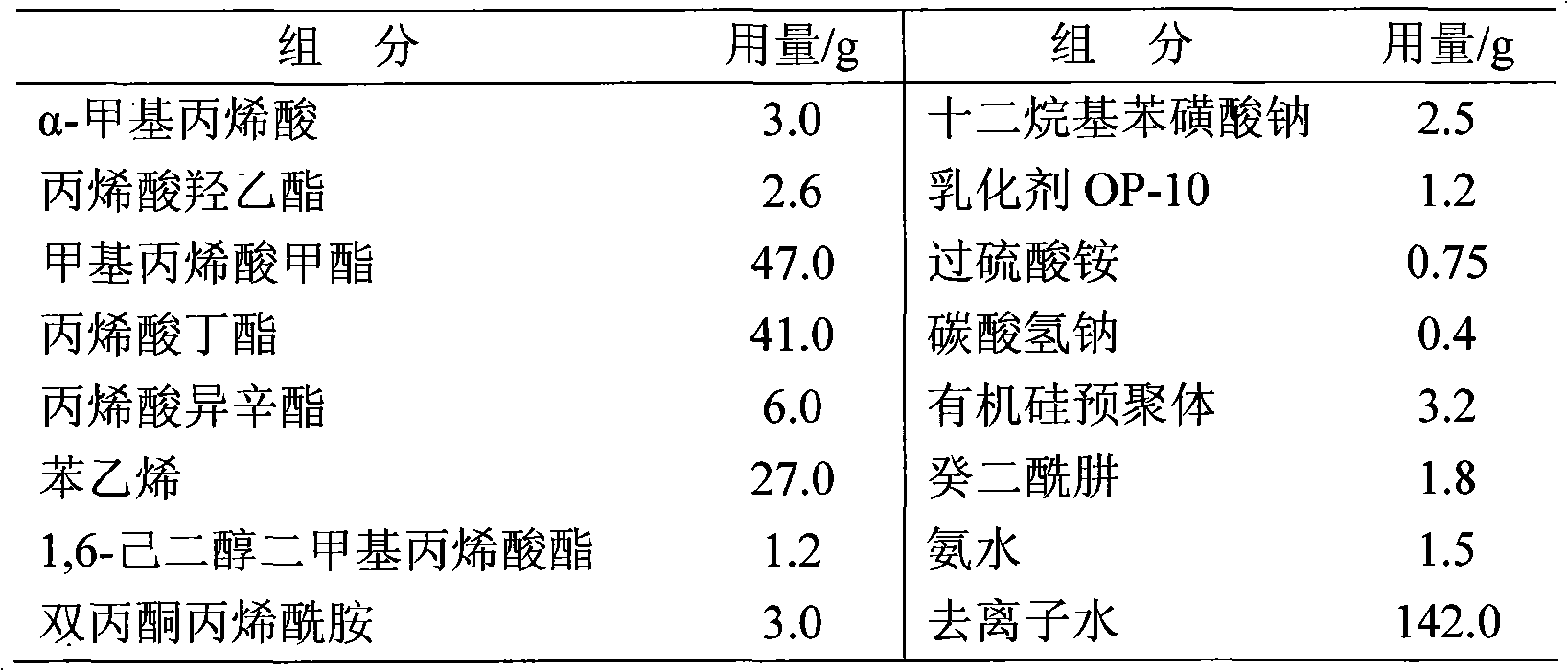

[0050] Silicone-modified acrylate water-based wood paint emulsion raw material formula is shown in Table 2:

[0051] Table 2 Silicone-modified acrylate emulsion formula

[0052]

[0053] Its synthetic method is:

[0054] ① Preparation of nuclear emulsion: 1.0g sodium dodecylbenzenesulfonate, OP-100.6g, 19g deionized water, 25g methyl methacrylate, 18g styrene, 6g isooctyl acrylate, 1,6 - 0.5 g of hexanediol dimethacrylate was successively added to the pre-emulsification tank, and stirred for 15 minutes to obtain the pre-emulsion of the nuclear monomer; 0.9 g of sodium dodecylbenzenesulfonate and bicarbonate 0.4g of sodium, 46g of deionized water, 7.5g of the pre-emulsion of nuclear monomer, add 20g of ammonium persulfate aqueous solution (0.75g of ammonium persulfate is dissolved in 37g of deionized water) when warming up to 50 ℃, and continue to heat up to 82 ±1°C, add the remaining nuclear monomer pre-emulsion and the remaining ammonium persulfate aqueous solution dropw...

Embodiment 3

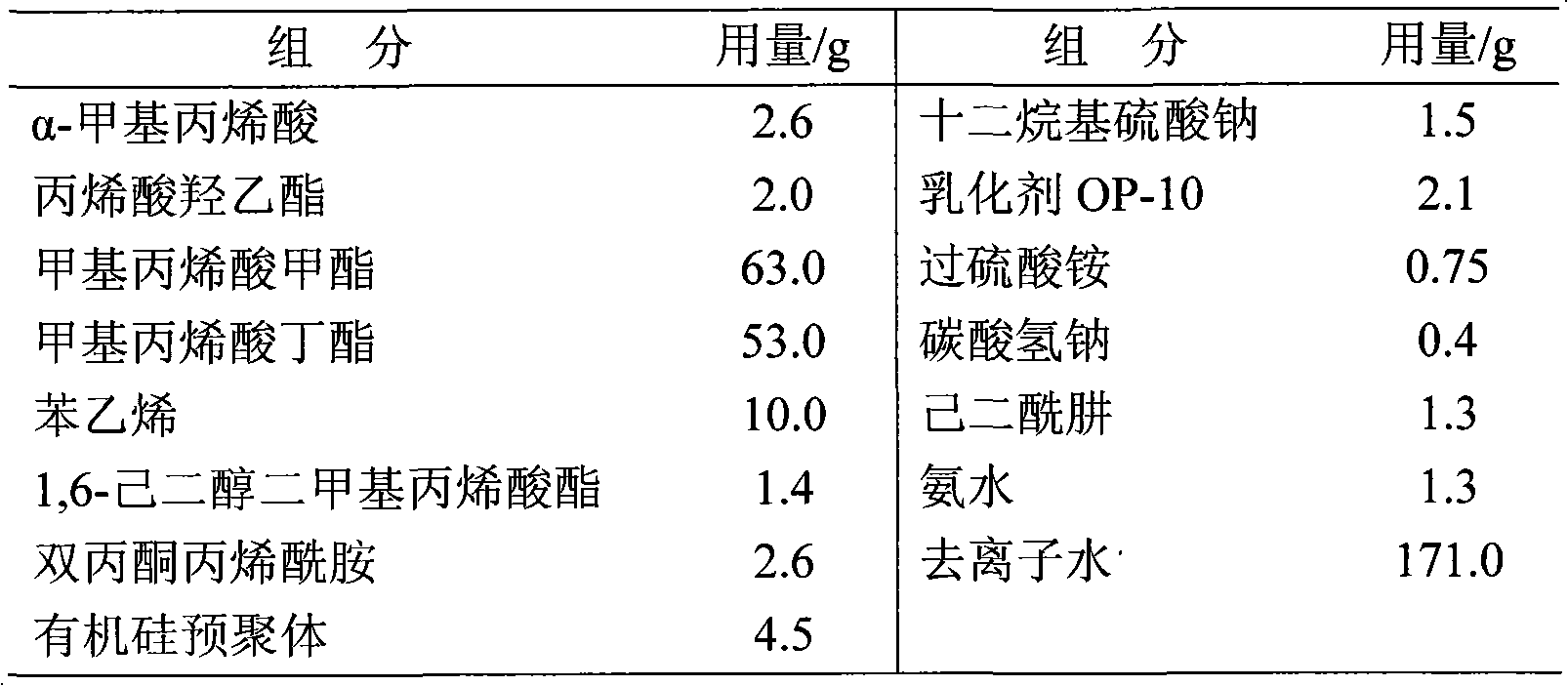

[0061] The raw material formula of silicone modified acrylate waterborne wood paint emulsion is shown in Table 3:

[0062] Table 3 Silicone-modified acrylate emulsion formula

[0063]

[0064] Its synthetic method is:

[0065] ① Preparation of nuclear emulsion: 0.5g of sodium lauryl sulfate, OP-100.6g, 20g of deionized water, 25g of methyl methacrylate, 10g of styrene, 18g of butyl methacrylate, 1,6- Add 0.8g of hexanediol dimethacrylate to the pre-emulsification tank in turn, and stir for 15 minutes to prepare the pre-emulsion of the nuclear monomer; add 0.5g of sodium lauryl sulfate, OP-100.5g to the polymerization tank in turn , sodium bicarbonate 0.4g, deionized water 56g, nuclear monomer pre-emulsion 8.5g, add 20g ammonium persulfate aqueous solution (dissolve ammonium persulfate 0.75g in 45g deionized water) when the temperature rises to 50°C, and continue Raise the temperature to 82±1°C, keep warm for 5 minutes, and add the remaining nuclear monomer pre-emulsion an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com