Method for producing refined light-color rosin by using turpentine as raw material

A technology of rosin and rosin, which is applied in the field of rosin production, can solve the problems of high temperature, large equipment investment, and high energy consumption, and achieve the effects of high softening point, low equipment investment, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

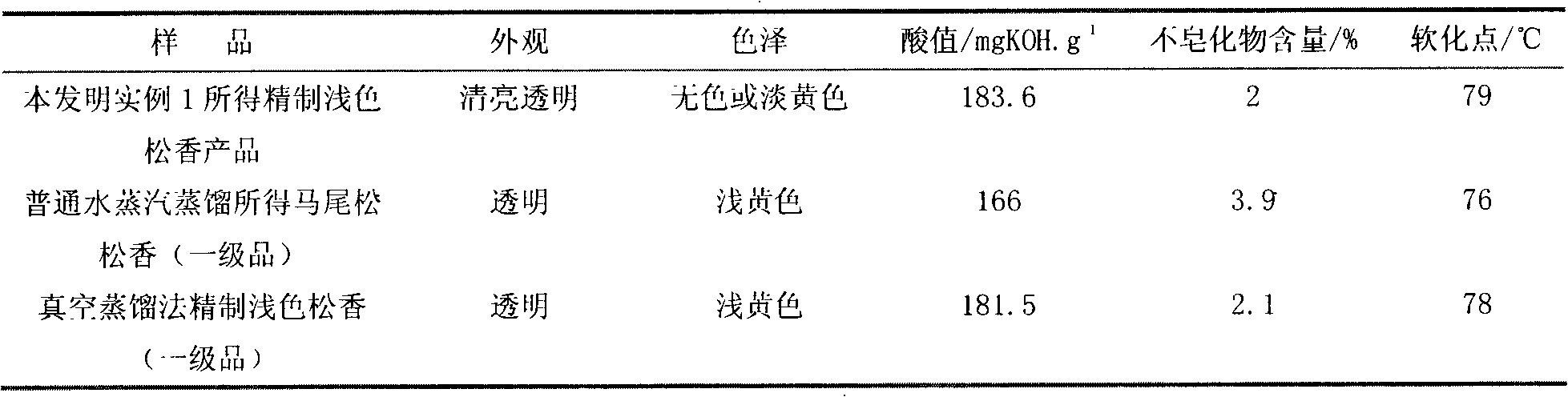

Examples

Embodiment 1

[0019] Take by weighing 50 grams of masson pine rosin, put it in a 100mL round-bottomed flask, add the benign solvent dichloromethane of pine resin after fully dissolving, the mass volume ratio of pine resin and dichloromethane is 10:8, filter to remove insoluble substances such as wood chips and bark, etc. Solid impurities; then, wash the fat liquid with oxalic acid aqueous solution to remove water-soluble impurities and resin acid iron salts, wherein the amount of oxalic acid is 0.05 to 0.1% of the mass of turpentine, divide the water phase, and add acetonitrile, rosin and acetonitrile to the organic phase under stirring The mass-to-volume ratio is 10:8, and white resin acid precipitates out and is in a dispersed state. Filter and separate resin acid precipitation, resin acid precipitation is combined, in N 2 or CO 2 Heating and melting treatment under protection, cooling and solidification to obtain rosin products. The selected benign solvent dichloromethane and the non-b...

Embodiment 2

[0021] Take by weighing 100 grams of masson pine rosin, put it in a 500mL round-bottomed flask, add the benign solvent dichloromethane of turpentine after fully dissolving, the mass volume ratio of pine resin and dichloromethane is 10:15, filter to remove wood chips, bark and other insoluble substances Solid impurities; then, wash the fat liquid with oxalic acid aqueous solution to remove water-soluble impurities and resin acid iron salts, wherein the amount of oxalic acid is 0.05 to 0.1% of the mass of turpentine, divide the water phase, and add acetonitrile, rosin and acetonitrile to the organic phase under stirring The mass-to-volume ratio is 10:25, and white resin acid precipitates out and is in a dispersed state. Filter and separate resin acid precipitation, resin acid precipitation is combined, in N 2 or CO 2 Heating and melting treatment under protection, cooling and solidification to obtain rosin products. The selected benign solvent dichloromethane and the non-benig...

Embodiment 3

[0023] Take by weighing 200 grams of masson pine rosin, put it in a 1000mL round-bottomed flask, add the benign solvent dichloromethane of turpentine after fully dissolving, the mass volume ratio of pine resin and dichloromethane is 10:15, filter to remove insoluble substances such as wood chips and bark, etc. Solid impurities; then, wash the fat liquid with oxalic acid aqueous solution to remove water-soluble impurities and resin acid iron salts, wherein the amount of oxalic acid is 0.05 to 0.1% of the mass of turpentine, divide the water phase, and add acetonitrile, rosin and acetonitrile to the organic phase under stirring The mass-to-volume ratio is 10:25, and white resin acid precipitates out and is in a dispersed state. Filter and separate resin acid precipitation, resin acid precipitation is combined, in N 2 or CO 2 Heating and melting treatment under protection, cooling and solidification to obtain rosin products. The selected benign solvent dichloromethane and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com