Vertical-type furnace for alpha-HgI2 single crystal growth and growth method of alpha-HgI2 single crystal

A mercury iodide single and vertical furnace technology, which is applied to chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of complex temperature control system, high production cost, single crystal damage, etc., and achieve process simplification and production The effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

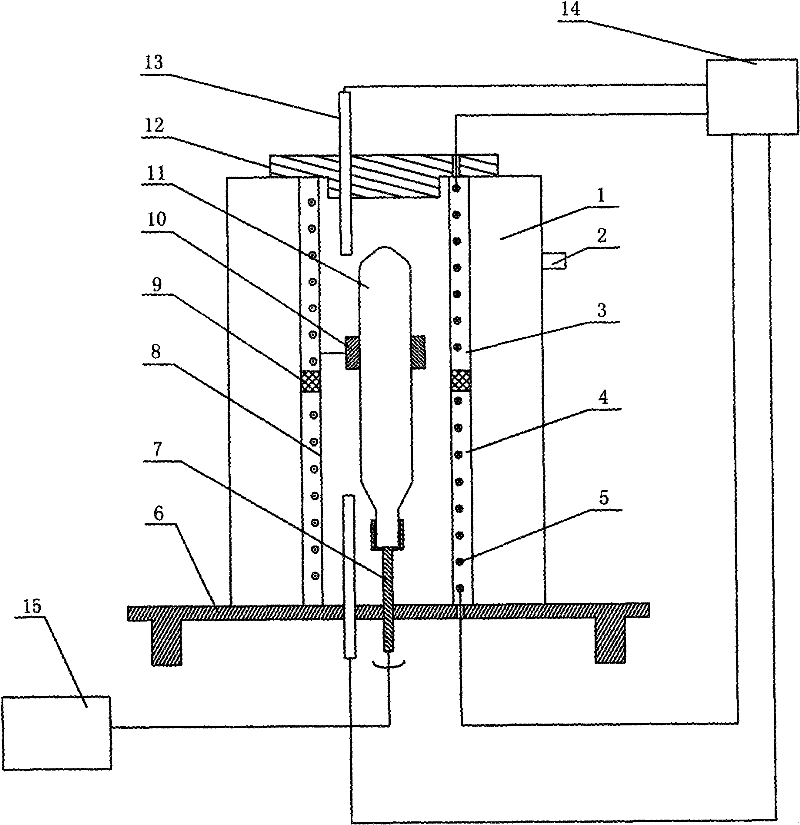

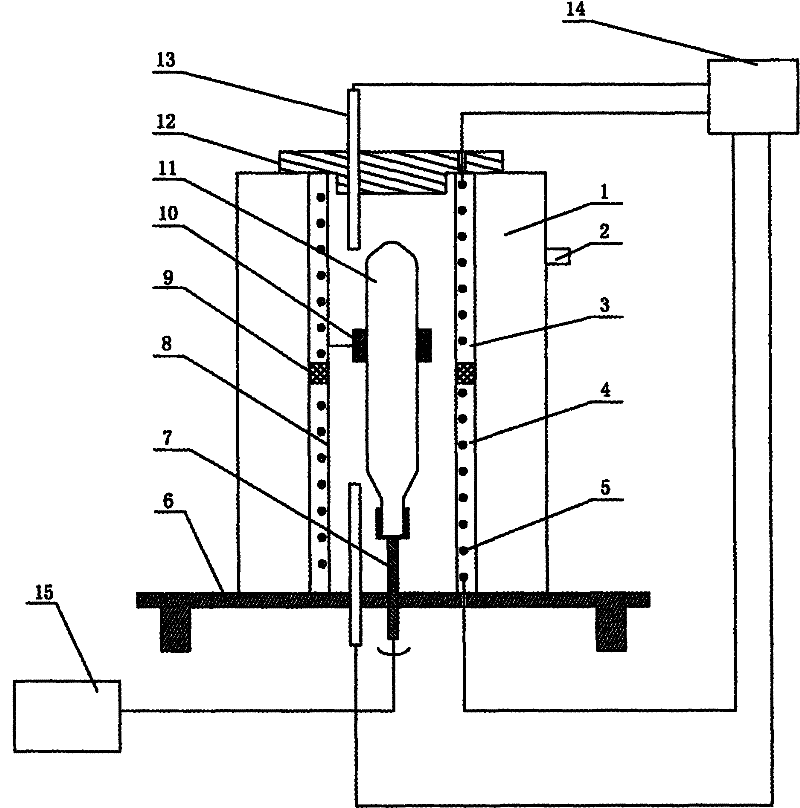

[0025] 1. Preparation: put 5N high-purity mercury iodide polycrystalline powder into the growth ampoule 11 and vacuumize to -10 -5 Torr and seal the tube, and drive the material in the horizontal furnace, so that the raw material is placed in the raw material area;

[0026] 2. Fixing of raw materials: Lift the metal pole 7 to the installation position through the lifting device, fix the crystal selection end of the growing ampoule 11 on the metal pole 7 downward, and adjust the position of the growing ampoule 11 through the metal pole 7; turn on the temperature The control system 14, the temperature control system 14 starts the heater in the lower cavity 4, and when the temperature of the crystal growth zone is 110°C, it starts to keep warm for 6 hours to drive away the raw materials that may slip;

[0027] 3. Crystal growth: start the heater and temperature control system 14 in the upper cavity 3, heat up and adjust the temperature (T original=118°C, T length=104°C), open the...

Embodiment 2

[0030] 1. Preparatory work: put 5N high-purity mercury iodide polycrystalline powder into the growth ampoule 11, and vacuumize to 10 -4 Torr and seal the tube;

[0031]2. Fixing of raw materials: Lift the metal pole 7 to the installation position through the lifting device, fix the crystal selection end of the growing ampoule 11 on the metal pole 7 downward, adjust the position of the growing ampoule 11 through the metal pole 7; turn on the temperature The control system 14, the temperature control system 14 starts the heater in the lower cavity 4, and when the temperature of the crystal growth area is 120°C, it starts to keep warm for 4 hours to drive away the raw materials that may slip;

[0032] 3. Crystal growth: start the heater and temperature control system 14 in the upper cavity 3, heat up and adjust the temperature (T original=120°C, T length=100°C), open the rotating assembly in the adjustment mechanism 15, and drive the metal The pole 7 rotates to make the growth a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com