Catalyst for aromatization of lower hydrocarbons and process for production of aromatic compounds

A kind of technology of aromatic compound and catalyst, applied in the field of preparation of said catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

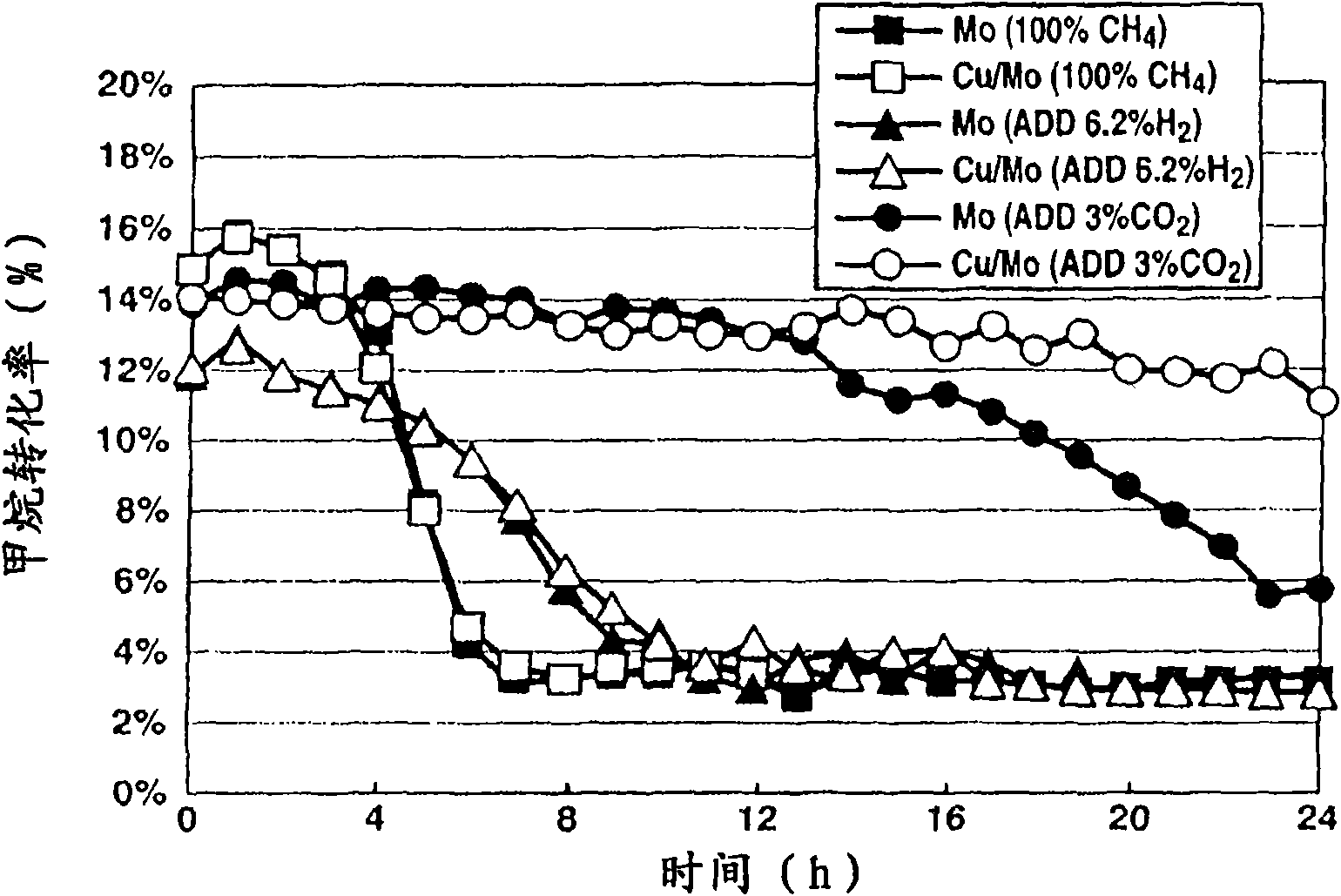

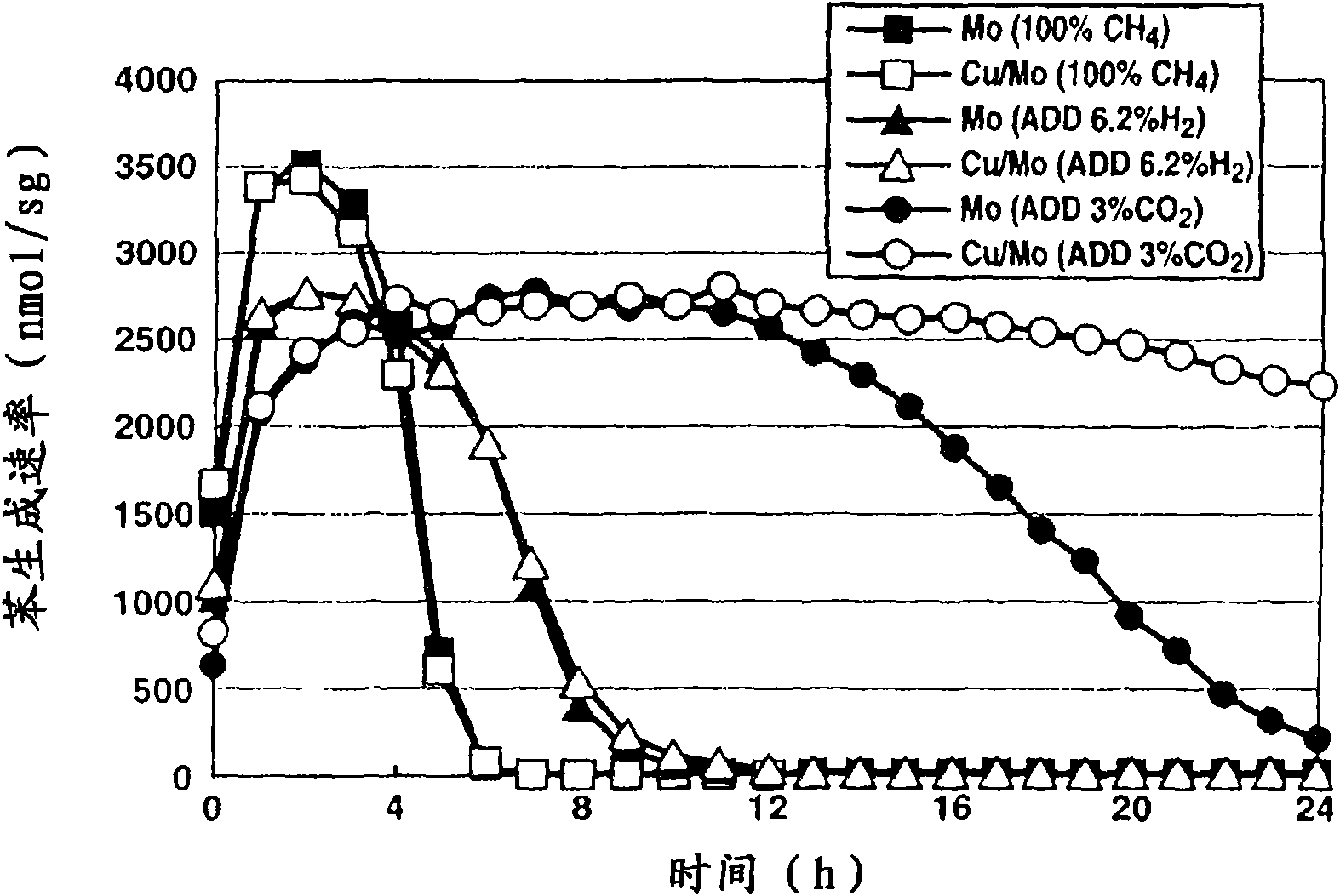

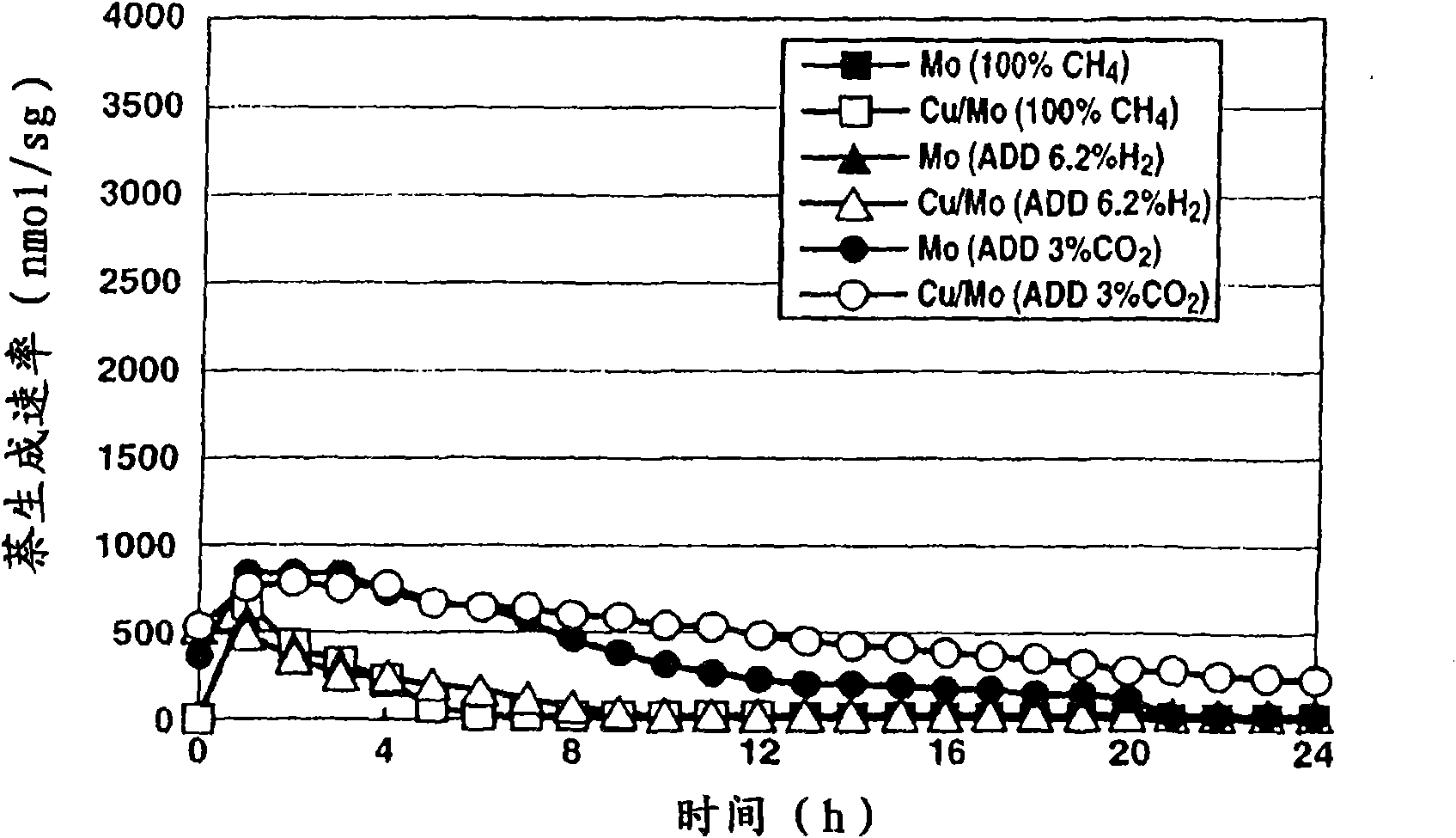

[0067] The catalyst of Example 1 was prepared by supporting molybdenum and copper. The catalyst of Example 1 was prepared by the same preparation method as that of the catalyst of Comparative Example 1 (including molding, drying, roasting and carburizing treatment), but the impregnation process was different.

[0068] In the impregnation process of Example 1, the impregnation solution prepared by copper acetate and ammonium molybdate was stirred, and then the shaped carrier ZSM-5 prepared in the molding method described in Comparative Example 1 was immersed in the stirred impregnation solution , thereby impregnating the shaped support with a molybdenum component and a copper component. The carrier was then dried and calcined in air to obtain a ZSM-5 carrier loaded with molybdenum and copper. When preparing the impregnating solution, it has been set that the loading of molybdenum is 6wt% based on the total amount of carrier after sintering, and the loading of copper is set acc...

Embodiment 2

[0096] The catalyst of Example 2 was prepared by loading copper and molybdenum according to the molar ratio of copper to molybdenum of 0.1:1.0. Using the same preparation method as the catalyst of Comparative Example 1 (including molding, drying, roasting and carburizing), the catalyst of Example 2 was prepared, but the size of the shaped carrier and the impregnation process were different.

[0097] In the molding process of this example, the mixture of inorganic components, organic binders and water described in Comparative Example 1 is extruded into strips (diameter 2.4mm, length 5mm). In the impregnation process of this example, the impregnation solution prepared by copper acetate and ammonium molybdate was stirred. The shaped carrier including ZSM-5 formed in the forming process is then immersed in the stirred impregnating liquid, thereby impregnating the shaped carrier with molybdenum component and copper component. The carrier was dried and then calcined in air to obta...

Embodiment 3

[0099] The catalyst of Example 3 was prepared by loading copper and molybdenum according to the molar ratio of copper to molybdenum of 0.3:1.0. Using the same preparation method as the catalyst of Comparative Example 1 (including molding, drying, roasting and carburizing), the catalyst of Example 3 was prepared, but the size of the shaped carrier and the impregnation process were different.

[0100] In the molding process of this example, the mixture of inorganic components, organic binders and water described in Comparative Example 1 is extruded into strips (diameter 2.4mm, length 5mm). In the impregnation process of this example, the impregnation solution prepared by copper acetate and ammonium molybdate was stirred. The shaped carrier including ZSM-5 formed in the forming process is then immersed in the stirred impregnating liquid, thereby impregnating the shaped carrier with molybdenum component and copper component. The carrier was dried and then calcined in air to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com