Silicon oxynitride combined carborundum high-temperature ceramic material and preparation method thereof

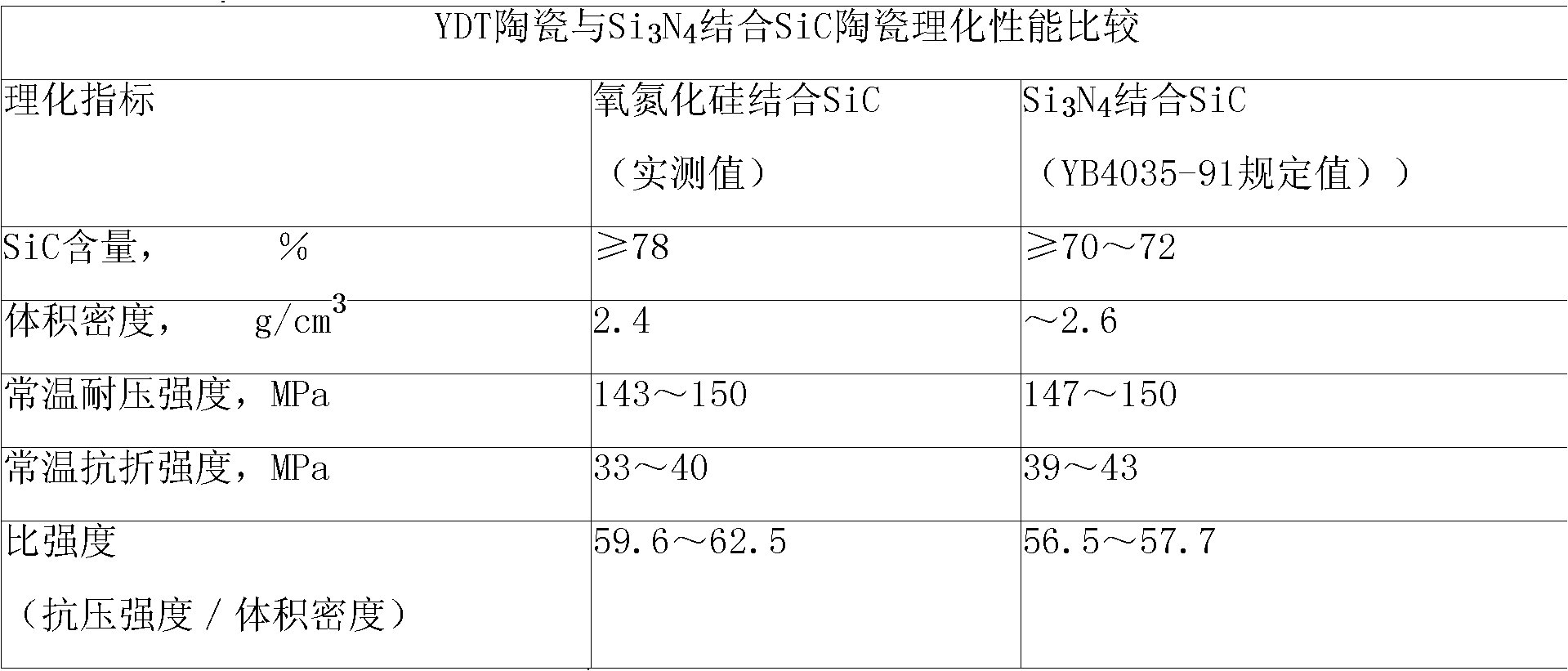

A high-temperature ceramic and silicon oxynitride technology, applied in the field of high-temperature ceramic materials, can solve the problems of high production cost, large equipment investment, long production cycle, etc., and achieve the effect of short process, low equipment investment, and no shape restrictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) The YDT silicon oxynitride bonded silicon carbide high-temperature ceramic material in this embodiment is composed of aggregate, powder, admixture, and binder, wherein:

[0047] Taking the sum of aggregate and powder mass as 100% of the total mass:

[0048] The aggregate content accounts for 70% of the total mass, and the powder content accounts for 30% of the total mass; the addition of vanadium pentoxide as an admixture is 0.3% of the total mass; the binder includes sodium lignosulfonate with a mass percentage concentration of 50% Solution (referring to aqueous solution, the same below), polyvinyl alcohol solution (referring to aqueous solution, the same below) with a concentration of 6% by mass percentage, and dextrin, the addition amount of the three is 4%, 1%, 0.4% of the total mass respectively;

[0049]The aggregate in the above components is silicon carbide aggregate, in which the SiC content is ≥ 97%; the particle size is: 1-2mm accounts for 15% of the tota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com