Preparation method of anti-bacterial hydrogel dressing

A hydrogel and aqueous solution technology, applied in the fields of medical science, absorbent pads, bandages, etc., can solve the problems of good adhesion and no function, and achieve good adhesion, high biocompatibility, and strong hydration performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

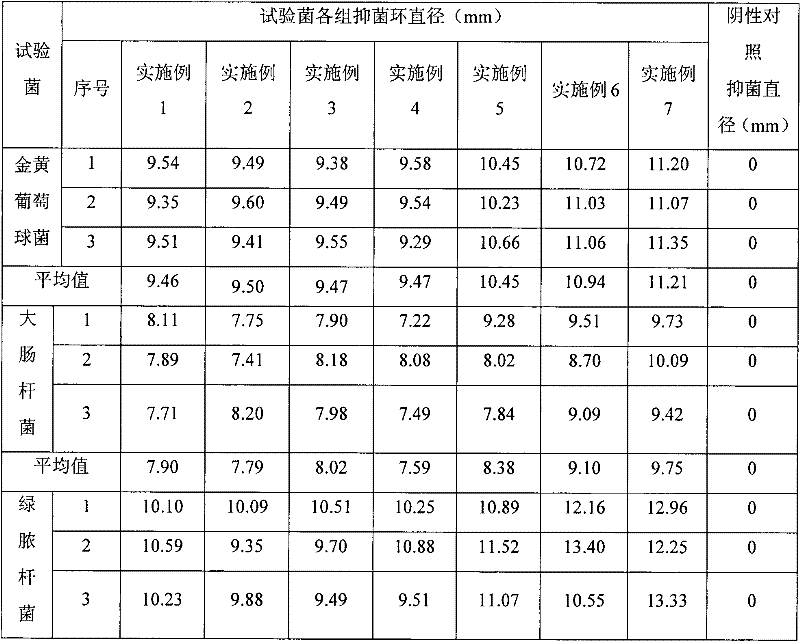

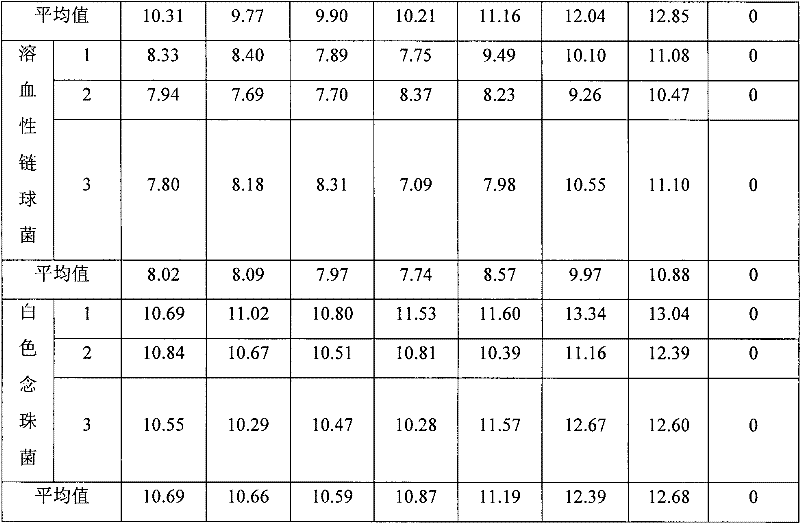

Examples

Embodiment 1

[0019] Embodiment 1, a kind of preparation method of antibacterial hydrogel dressing, carry out the following steps successively:

[0020] 1) 50g of double-ended hydroxyl polyethylene glycol (molecular weight is 2000) after azeotropic dewatering of toluene is dissolved in 200ml of dry tetrahydrofuran, and 25ml of acryloyl chloride is slowly added dropwise (15 drops / min) in an ice bath, After dropping, the ice bath was removed, and the reaction was carried out at room temperature for 8 h under nitrogen protection. The obtained reactant was filtered to remove the solid to obtain a clear liquid; the clear liquid was evaporated to dryness at 60° C. to obtain a crude product. The crude product was washed three times with saturated sodium chloride solution (200ml×3), then dissolved in 100ml of dichloromethane, placed in a nitrogen blower (Hangzhou Aosheng Instrument Co., Ltd.) to concentrate the organic phase, and the solution volume was reduced to the original. 40% of the volume; ...

Embodiment 2

[0023] Example 2, a preparation method of an antibacterial hydrogel dressing, changing the collagen in step 2) of Example 1 into dextran; obtaining a dextran aqueous solution containing nano-Ag; The collagen aqueous solution was changed to dextran aqueous solution, and the irradiation dose was changed to 40KGy; the rest were the same as in Example 1.

[0024] Antibacterial hydrogel dressings with a thickness of 0.5 mm and a solid content of 25.0% were obtained by polymerization in a mold.

Embodiment 3

[0025] Example 3. A method for preparing an antibacterial hydrogel dressing. The collagen in step 2) of Example 1 was changed to hyaluronic acid; a hyaluronic acid aqueous solution containing nano-Ag was obtained; the collagen in step 3) of Example 1 was changed into The aqueous solution was changed to hyaluronic acid aqueous solution, and the irradiation dose was changed to 80KGy; the rest were the same as in Example 1.

[0026] The antibacterial hydrogel dressing with a thickness of 0.5 mm and a solid content of 33.8% was obtained by polymerization in a mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com