Acrylate resin quartzite floor coating and preparation method thereof

An acrylate and acrylate technology, applied in the field of acrylate resin quartz stone floor paint and its preparation, can solve the problems of low one-time film-forming thickness and slow film-forming speed, and achieve low molecular weight, good compatibility, The effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

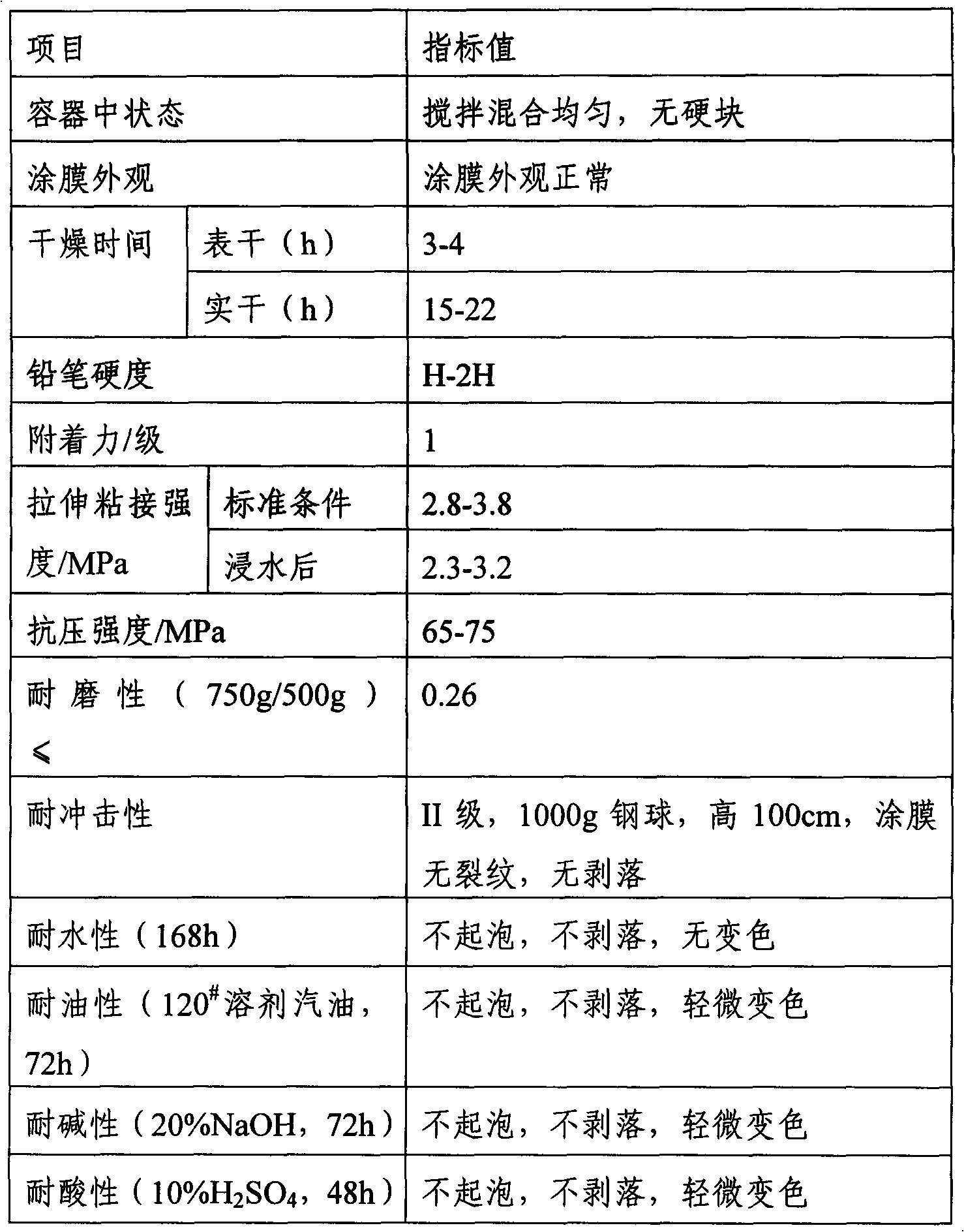

Embodiment 1

[0051] Environmental protection type acrylate resin quartz stone floor paint of the present invention comprises following components: methyl methacrylate 20kg, styrene 8kg, ethyl acrylate 5kg, benzoyl peroxide 0.1kg, ascorbic acid 0.05kg, tetraethylene Pentamine 0.03kg, BYK346 0.5kg, BYK P104 3kg, BYK 088 0.5kg, natural colored quartz 50kg, corundum 10kg, calcium carbonate 5kg.

[0052] Its preparation method is as follows:

[0053] 1) According to the above ratio, add methyl methacrylate, styrene, ethyl acrylate, 2 / 3~3 / 4 benzoyl peroxide and ascorbic acid into the reaction kettle, feed nitrogen, heat at 45°C, and react for 1.5 Hour. A VOC-free, low-viscosity oligomer is prepared.

[0054] 2) Add 1 / 3 of the total weight of the above-mentioned oligomer resin, BYK P104 and BYK088 into the dispersing kettle, and stir for 30 minutes at a speed of 500 rpm to make the materials evenly mixed;

[0055]3) Add the formula amount of corundum, natural colored quartz stone, calcium carb...

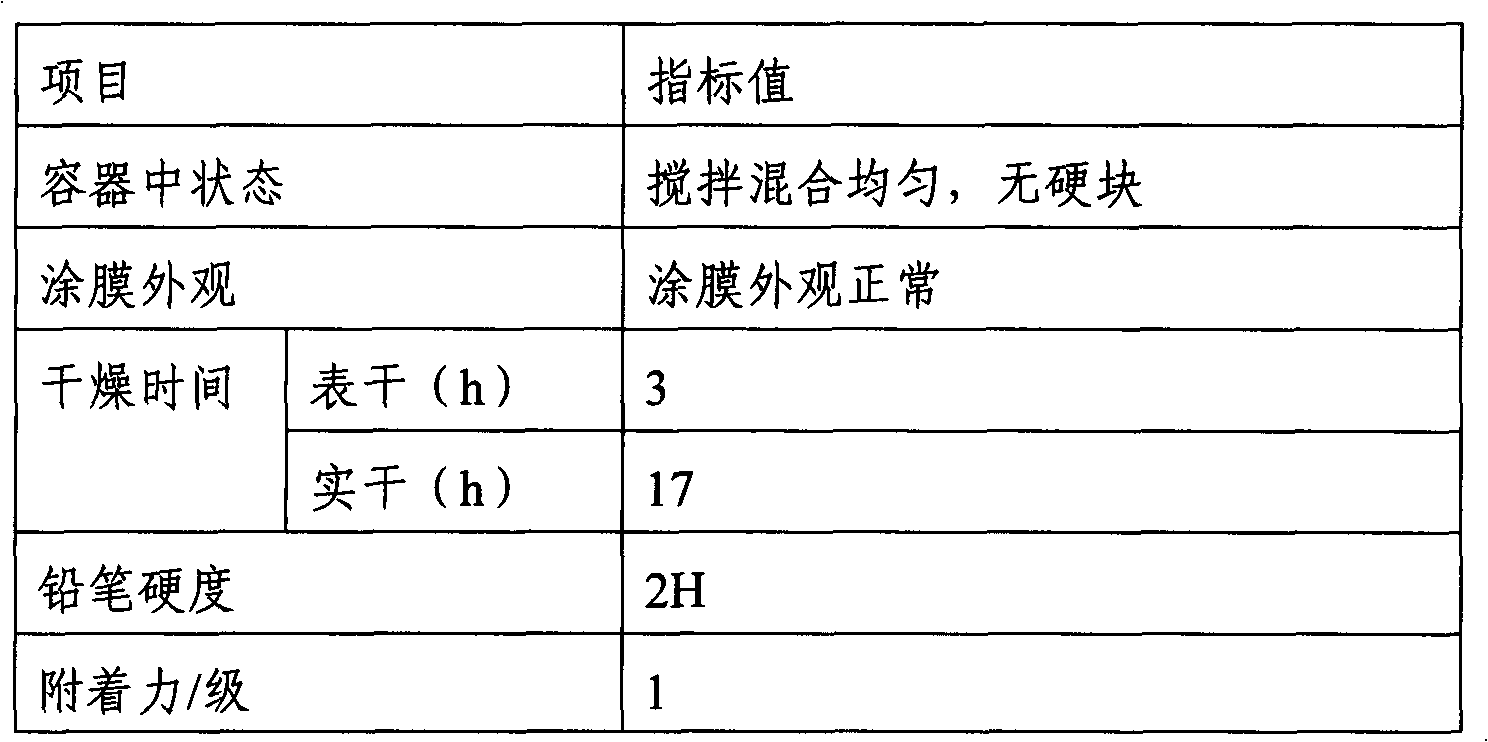

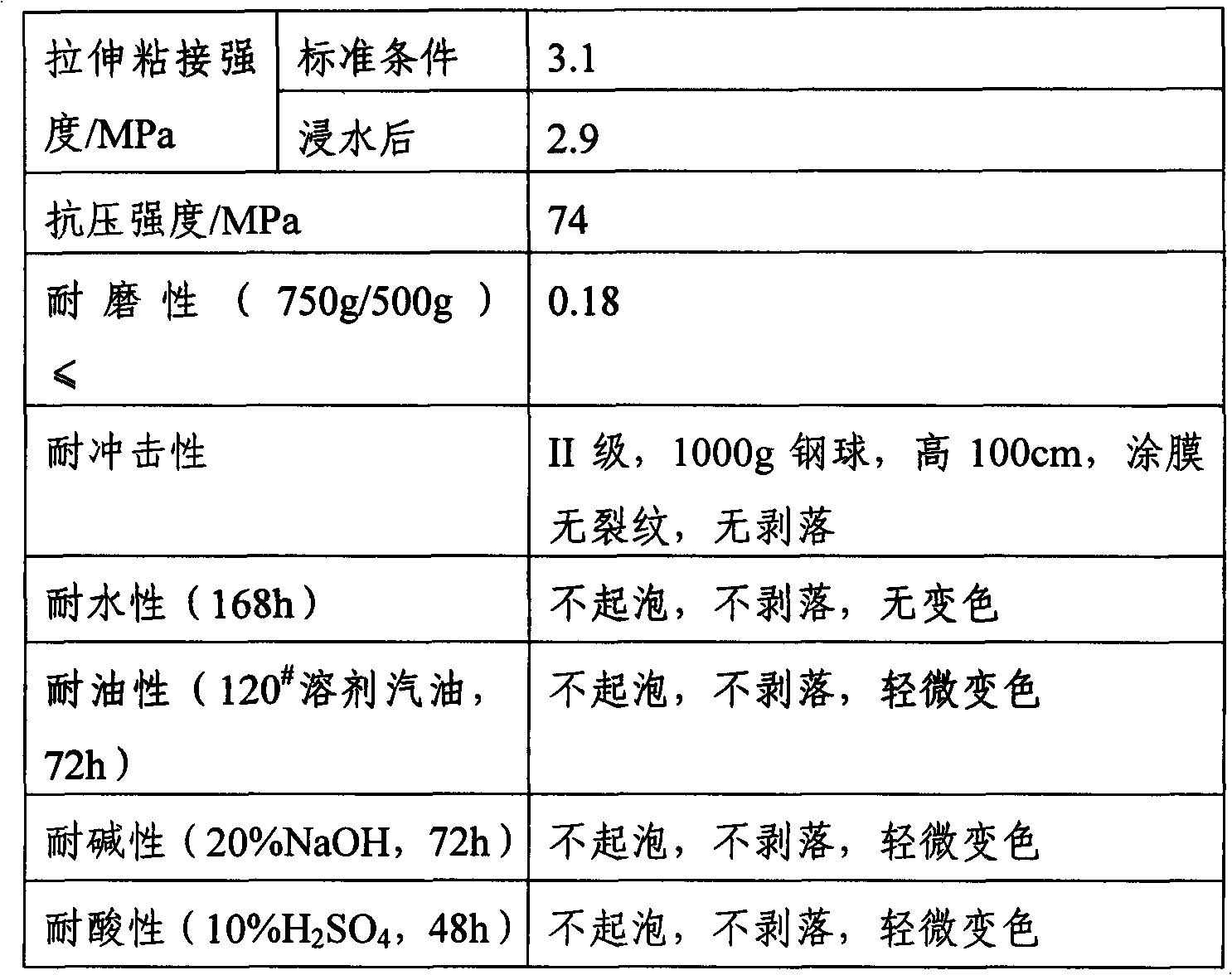

Embodiment 2

[0061] Acrylate resin quartz stone floor paint of the present invention comprises following components: methyl methacrylate 30kg, hydroxyethyl acrylate 10kg, benzoyl peroxide 0.1kg, sodium sulfite 0.05kg, tetraethylene pentamine 0.01 kg, BYK P104 1kg, BYK088 0.5kg, natural colored quartz stone 45kg, barium sulfate 6kg, BYK 996 2kg.

[0062] Its preparation method is:

[0063] 1) Add the prescribed amount of methyl methacrylate, hydroxyethyl acrylate, BYK P104, 2 / 3 of BYK088 into the dispersion kettle, and stir at 400rpm for 25 minutes to make the materials evenly mixed;

[0064] 2) Add the formula amount of barium sulfate, natural colored quartz stone, and the remaining amount of defoamer in sequence, and stir for 1.5 hours at a speed of 700 rpm to make the materials evenly mixed;

[0065] 3) Add the formula amount of BYK996 and stir for 20 minutes at 400rpm to make the materials evenly mixed.

[0066] 4) During construction, add benzoyl peroxide, sodium sulfite and tetraeth...

Embodiment 3

[0070] The environmental protection type acrylate resin quartz stone floor paint of the present invention comprises following components: vinyl acetate 3kg, styrene 25kg, benzoyl peroxide 0.1kg, glucose 0.05kg, N, N-dimethyl p-toluidine 0.01kg, BYK P104 3kg, BYK 088 0.5kg, natural colored quartz 60kg, wollastonite 5kg.

[0071] Its preparation method is as follows:

[0072] 1) According to the above ratio, add 3kg of vinyl acetate, styrene, 2 / 3 benzoyl peroxide and glucose into the reaction kettle, feed nitrogen, keep the temperature at 40°C, and react for 1.5 hours. A VOC-free, low-viscosity oligomer is prepared.

[0073] 2) Add the above-mentioned oligomer resin, BYK P104, and 1 / 3 BYK 088 into the dispersion kettle, and stir for 30 minutes at a speed of 500 rpm to make the materials evenly mixed;

[0074] 3) Add the formulated amount of natural colored quartz stone, wollastonite, and the remaining amount of defoamer in sequence, and stir at 650 rpm for 2 hours to make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com