Nickel ordered porous array film and preparation method thereof

A porous array and thin film technology, applied in the field of nickel ordered porous array thin film and its preparation, can solve the problems of restricting performance and wide application fields, complicated preparation of polystyrene single-layer colloidal crystal template, etc. Large, coercive force and remanence increase, the effect of scientific preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

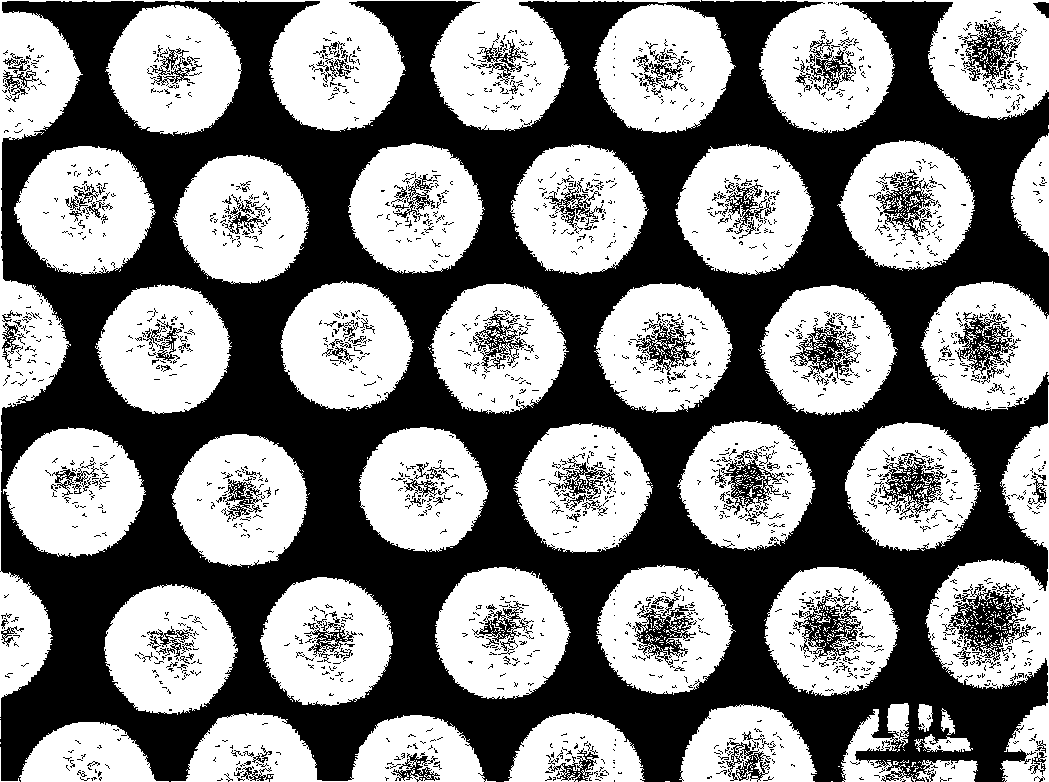

[0022]The specific steps of preparation are as follows: step 1, first place the polystyrene suspension with a colloidal sphere diameter of 1000 nm on a rotating flat substrate to obtain a tightly packed single-layer colloidal crystal template, and then immerse the single-layer colloidal crystal template in water, After it is detached from the substrate and floats on the water surface, pick it up with a substrate of required material and shape, and make it cover the surface of the substrate, and then heat it at a temperature of 60°C for 15 minutes; The rotation speed of the substrate is 50r / min, the water is deionized water, and the substrate is a planar insulator. Afterwards, it was etched with plasma for 6 minutes under an argon atmosphere, and then heated at 60° C. for 15 minutes; wherein, the etching power was 18 W when plasma was etched, and the following figure 1 The non-densely packed monolayer colloidal crystal template shown.

[0023] Step 2, first place the single-la...

Embodiment 2

[0025] The specific steps of preparation are as follows: step 1, first place the polystyrene suspension with a colloidal sphere diameter of 1250nm on a rotating flat substrate to obtain a tightly packed single-layer colloidal crystal template, and then immerse the single-layer colloidal crystal template in water, After it is detached from the substrate and floats on the water surface, pick it up with a substrate of required material and shape, and cover it on the surface of the substrate, and then heat it at 80°C for 13 minutes; The rotation speed of the substrate is 60r / min, the water is deionized water, and the substrate is a planar insulator. Afterwards, it was etched with plasma for 25 min under an argon atmosphere, and then heated at 80° C. for 13 min; wherein, the etching power was 15 W when plasma was etched, and an approximate figure 1 The non-densely packed monolayer colloidal crystal template shown.

[0026] Step 2, first place the single-layer colloidal crystal tem...

Embodiment 3

[0028] The specific steps of preparation are as follows: step 1, first place the polystyrene suspension with a colloidal sphere diameter of 1500nm on a rotating flat substrate to obtain a tightly packed single-layer colloidal crystal template, and then immerse the single-layer colloidal crystal template in water, After it is detached from the substrate and floats on the water surface, pick it up with a substrate of required material and shape, and cover it on the surface of the substrate, and then heat it at a temperature of 100°C for 10 minutes; The rotation speed of the substrate is 65 r / min, the water is deionized water, and the substrate is a planar insulator. Afterwards, it was first placed in an argon atmosphere and etched with plasma for 50 minutes, and then heated at a temperature of 100 ° C for 8 minutes; wherein, the etching power was 12 W during plasma etching, and an approximate figure 1 The non-densely packed monolayer colloidal crystal template shown.

[0029] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com