Microwave electrochemical method for processing waste water and devices thereof

A technology for wastewater treatment and electrochemistry, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc. problems, to achieve the effect of not easily damaged by microwaves, stable surface state, and wide potential window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

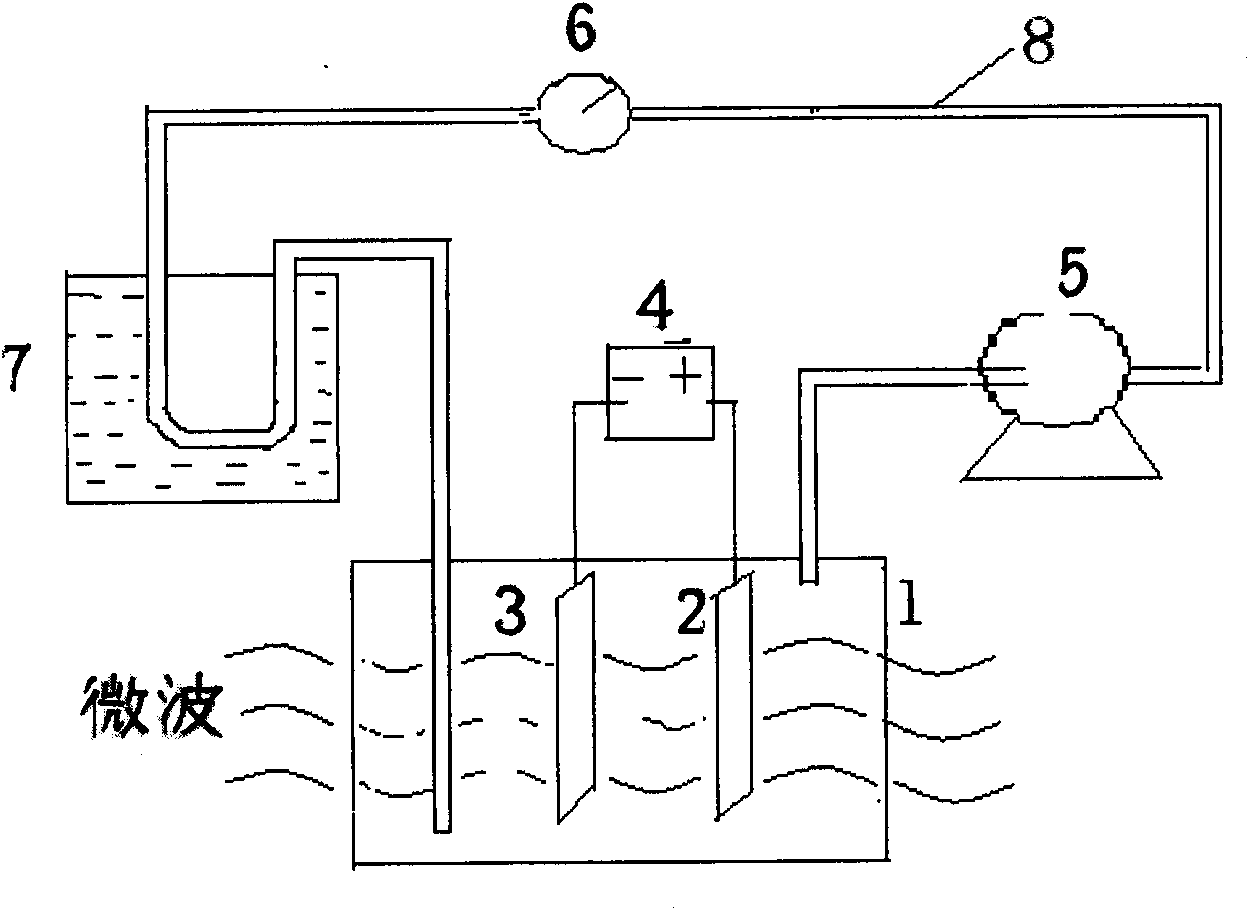

[0023] Embodiment 1: as figure 2 As shown, the device is composed of a reactor 1, an anode 2, a cathode 3, a DC power supply 4, a peristaltic pump 5, a flow meter 6, a constant temperature tank 7 and a pipeline 8. The anode 2 is a boron-doped diamond film electrode, and the cathode 3 is a titanium electrode, wherein: the anode 2 and the cathode 3 are respectively placed in the reactor 1, and the anode 2 and the cathode 3 are energized by a DC power supply 4, and the reactor 1 is placed in a microwave oven. One end of 1 is inserted into the reactor 1, and the other end passes through the peristaltic pump 5, the flow meter 6, and the constant temperature tank 7 in sequence, and is inserted into the reactor 1, so as to realize flow cycle sample injection degradation.

Embodiment 2

[0024] Example 2, with 2,4-dichlorophenoxyacetic acid wastewater as the water sample to be treated

[0025] COD of water samples Cr It is 115mg / L, the pH is 6, the concentration of supporting electrolyte sodium sulfate is 0.05mol / L, and the volume is 100ml. The area of boron-doped diamond film electrode and titanium electrode as anode and cathode respectively is 5.5cm 2 , the electrode spacing is 1cm, the current density is 20mA / cm 2 Carry out constant current degradation, the microwave frequency is 2450MHz, and the power is 120W. The effects were compared with the single electrochemical degradation as a comparative test. COD of electrochemical oxidation degradation alone for 3h Cr The removal rate was only 54%; the removal rate was greatly increased to 88% when the microwave-enhanced boron-doped diamond film electrode electrochemical oxidation technology was used for 3 hours, and the removal rate increased by 63%.

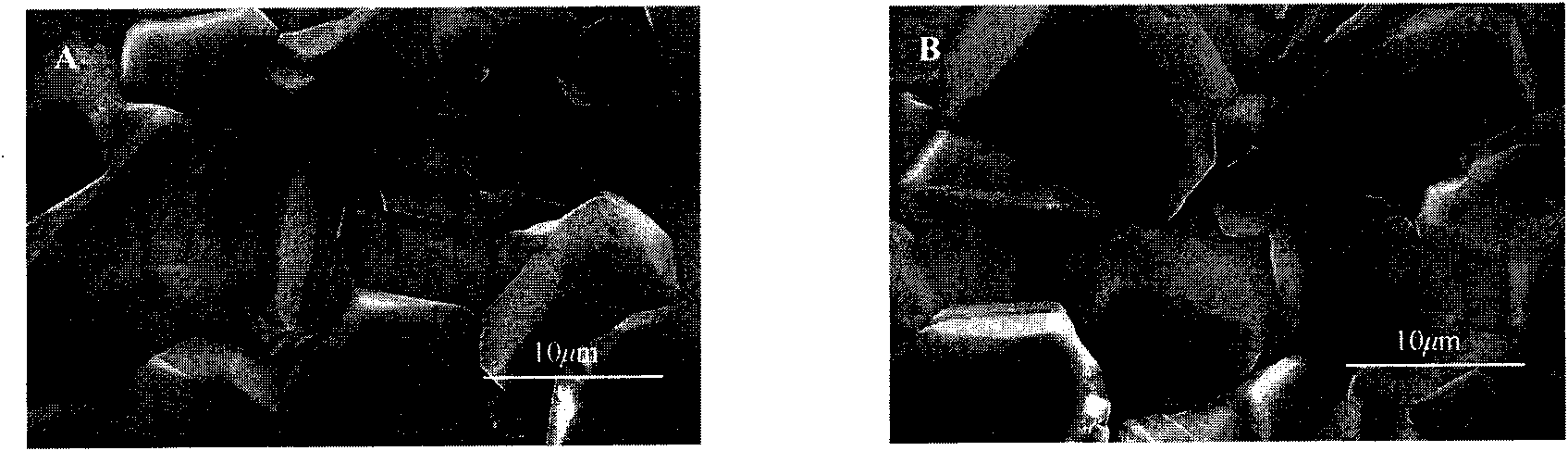

[0026] Depend on figure 1 Visible (the model of SEM ...

Embodiment 3

[0027] Embodiment 3 uses methyl orange wastewater as the water sample to be treated

[0028] The TOC (total organic carbon) of the water sample is 101.5mg / L, the pH is 5, the concentration of the supporting electrolyte sodium sulfate is 0.05mol / L, and the volume is 100ml. The area of boron-doped diamond film electrode and titanium electrode as anode and cathode respectively is 5.5cm 2 , the pole spacing is 1cm, the current density is 20mA / cm 2 Carry out constant current degradation, the microwave frequency is 2450MHz, and the power is 120W. The effects were compared with the single electrochemical degradation as a comparative test. COD of electrochemical oxidation degradation alone for 3h Cr The removal rate is only 49%; the removal rate is greatly increased to 96% when the microwave-enhanced boron-doped diamond film electrode electrochemical oxidation technology is used for 3 hours, and the removal rate is increased by 96%.

[0029] In the large-scale treatment equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com