Method for preparing low-temperature sintering ceramic dielectric material and obtained MLCC capacitor

A technology of low-temperature sintering ceramics and dielectric materials, which is applied in the field of ceramic dielectric materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

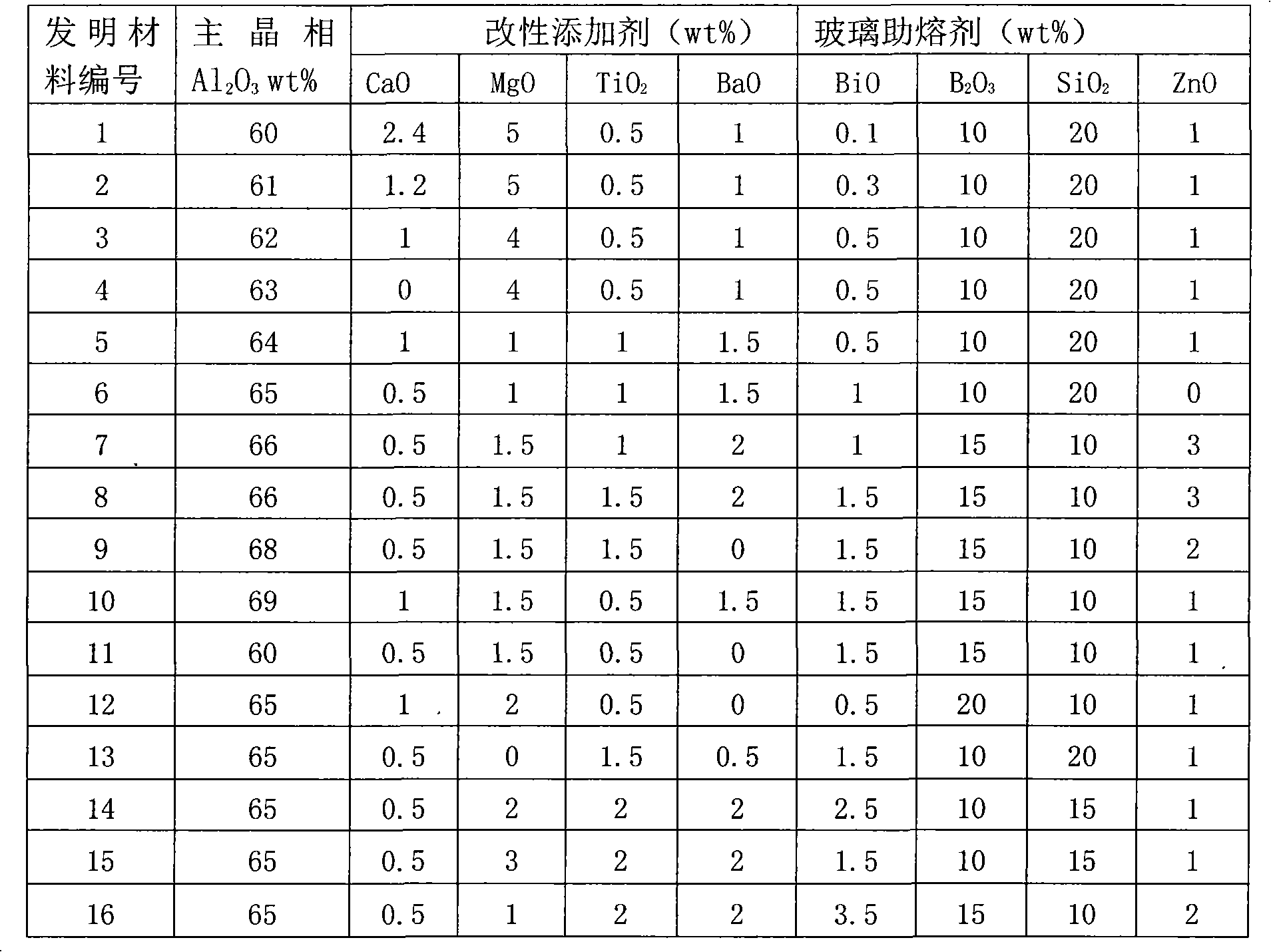

[0012] A low-temperature sintered ceramic dielectric material, the purity of which is selected to be analytically pure raw material Al 2 o 3 , adding modified additives, according to the No. 1-16 formula in Table 1, after fine-tuning the components, wet ball milling, sand milling, drying and other processes, the main material with good dispersion and uniform composition can be obtained. Measure the glass flux according to No. 1-16 formula in Table 1, and after fine-tuning the components, wet mixing, drying, and calcination, a glass material with good dispersibility and uniform composition can be obtained. Mix the above-mentioned main material and glass material according to the formula No. 1-16 in Table 1 to obtain a ceramic medium porcelain material, and prepare a ceramic slurry by a conventional method, and finally pass the slurry through casting, silk screen printing, lamination, cutting, Multilayer ceramic capacitor MLCC products are made by sintering and end-capping proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com