Preparation method of Bi0.5Na0.5Cu3Ti4O12 giant dielectric non-linear pressure-sensitive ceramics

A pressure-sensitive ceramic, non-linear technology, applied in the field of electronic information component materials, can solve the problem of no record, etc., and achieve the effects of large dielectric constant, simple operation and short cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

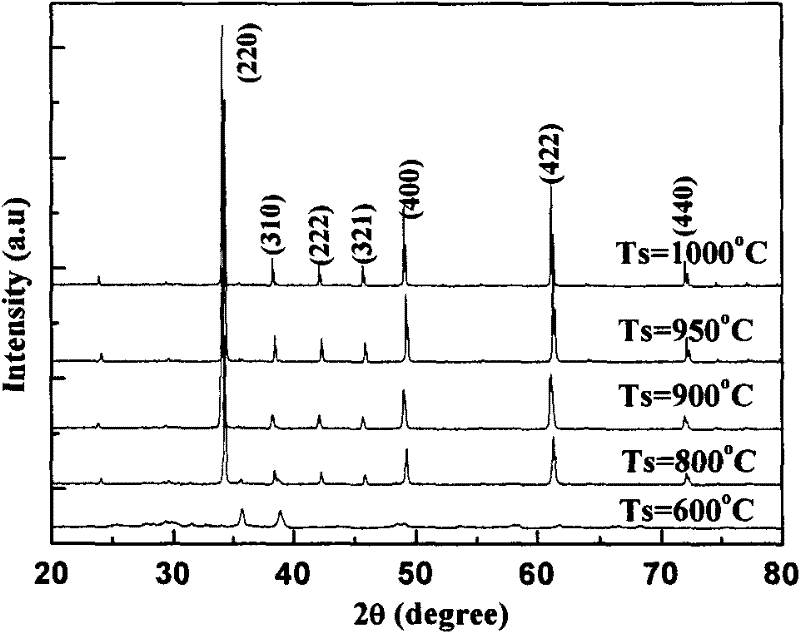

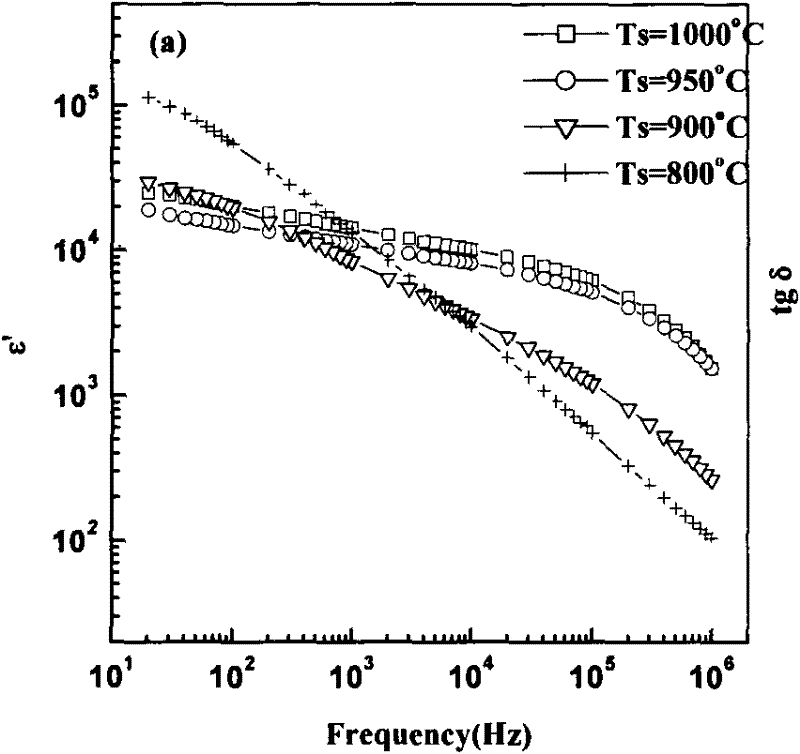

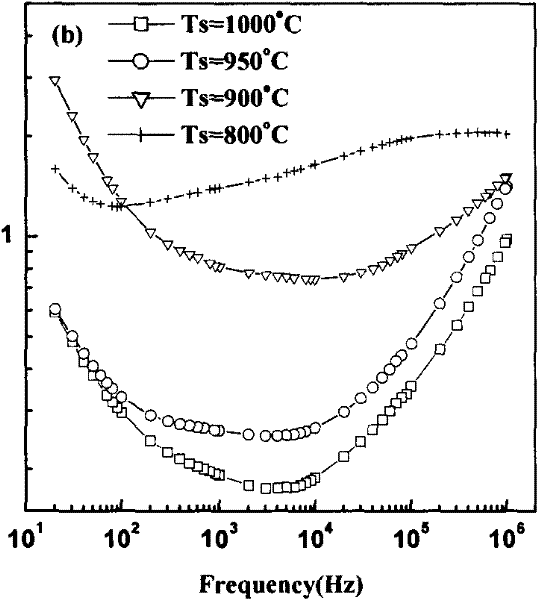

Embodiment 1

[0019] Preparation of Bi by Sol-Gel Method Using Citric Acid and Tetraethylamine Oxalate as Complexing Agents 0.5 Na 0.5 Cu 3 Ti 4 o 12 ceramics. First, weigh 0.08mol of citric acid into a 100mL beaker, add 40mL of deionized water, and dissolve under ultrasonic dispersion to form a transparent solution; then weigh 0.04mol of butyl titanate with a graduated straw and transfer it into a 100mL beaker ; Add citric acid aqueous solution to butyl titanate under constant stirring, then ultrasonically disperse for 30 minutes, and heat it in a water bath at 50°C to form a transparent solution with a concentration of 0.5mol / L. The molar ratio is 1:2. In the second step, weigh 0.04mol of tetraethylamine oxalate and put it into a 500mL beaker, add 40mL of deionized water, adjust the pH value to 6 with ammonia water, then weigh 0.005mol of bismuth nitrate, 0.005mol of sodium nitrate and 0.03 mol copper nitrate is added to the above solution, ultrasonically dispersed to form a transpa...

Embodiment 2

[0023]Preparation of Bi by Sol-Gel Method Using Citric Acid and Tetraethylamine Oxalate as Complexing Agents 0.5 Na 0.5 Cu 3 Ti 4 o 12 ceramics. First, weigh 0.08mol of citric acid into a 100mL beaker, add 50mL of deionized water, and dissolve it under ultrasonic dispersion to form a transparent solution; then weigh 0.04mol of butyl titanate with a graduated straw and transfer it into a 100mL beaker ; Add citric acid aqueous solution to butyl titanate under constant stirring, then ultrasonically disperse for 30 minutes, and heat it in a water bath at 50°C to form a transparent solution with a concentration of 1.5mol / L. The molar ratio is 2:5. In the second step, weigh 0.04mol of tetraethylamine oxalate and put it into a 500mL beaker, add 20mL of deionized water, adjust the pH value to 6.5 with ammonia water, then weigh 0.005mol of bismuth nitrate, 0.005mol of sodium nitrate and 0.03 mol of copper nitrate was added to the above solution, ultrasonically dispersed to form a...

Embodiment 3

[0027] Preparation of Bi by Sol-Gel Method Using Citric Acid and Tetraethylamine Oxalate as Complexing Agents 0.5 Na 0.5 Cu 3 Ti 4 o 12 ceramics. First, weigh 0.08mol of citric acid into a 100mL beaker, add 30mL of deionized water, dissolve under ultrasonic dispersion, and form a transparent solution; then weigh 0.04mol of butyl titanate with a graduated straw, and transfer it into a 100mL beaker ; Add citric acid aqueous solution to butyl titanate under constant stirring, then ultrasonically disperse for 30 minutes, and heat it in a water bath at 50°C to form a transparent solution with a concentration of 0.9mol / L. The molar ratio is 1:2. In the second step, weigh 0.04mol of tetraethylamine oxalate and put it into a 500mL beaker, add 40mL of deionized water, adjust the pH value to 6.7 with ammonia water, then weigh 0.005mol of bismuth nitrate, 0.005mol of sodium nitrate and 0.03 mol of copper nitrate was added to the above solution, ultrasonically dispersed to form a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com