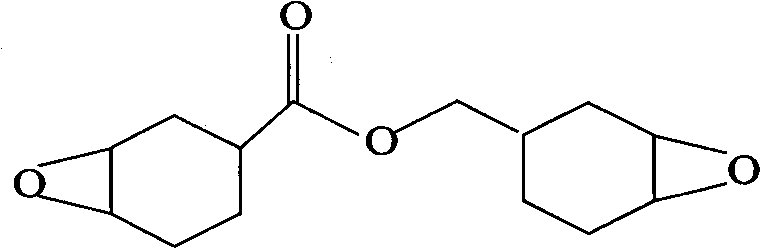

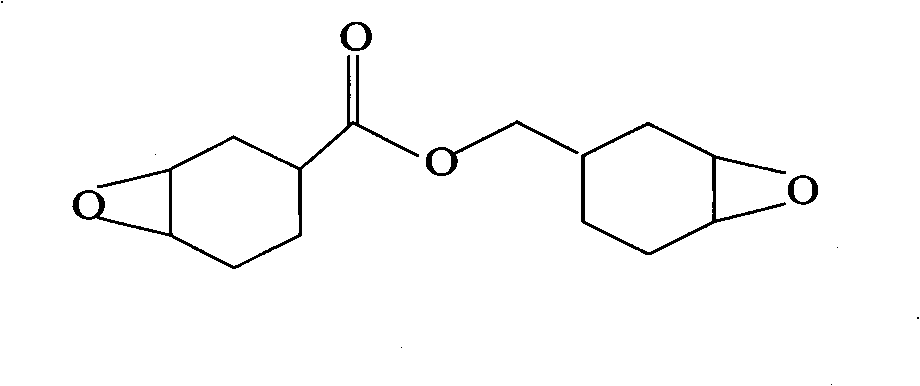

Cycloaliphatic epoxy resin and preparation method thereof

An epoxy resin, cycloaliphatic technology, applied in the direction of organic chemistry, etc., can solve the problems of difficult solvent recovery and reuse, complex system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of preparation method of cycloaliphatic epoxy resin, the steps are as follows:

[0022] (1) Preparation of oxidant solution containing catalyst

[0023] Weigh 46.0 g of hydrogen peroxide (35%), 30.0 g of chloroform, and 2.2 g of catalyst heteropolyacid; add them to a 250 ml single-necked flask, install the stirrer, and adjust the pH value to 2.4- 3.0 range; stir for 90 minutes to mix the solution into a uniform milky solution; pour it into the dropping funnel for use.

[0024] (2) Weigh 44g of bicycloalkenyl ester and 80g of chloroform respectively, add them into a 500ml four-neck flask, install a stirrer, a thermometer, a dropping funnel, and a water separation condensing device. Stir, and when the temperature rises to 60-65°C, reflux occurs; start dropping the oxidant solution in the dropping funnel, maintain the system temperature at about 60-65°C, and complete the dropwise addition in 60-90 minutes; continue to react for 60 minutes. After stan...

Embodiment 2

[0028] Weigh 54.0 g of hydrogen peroxide (30% content) and 30.0 g of toluene, and 2.2 g of catalyst heteropolyacid respectively; 2 CH 2 PO 3 h 2 , adjust the pH value to the range of 2.0-2.7; stir for 120 minutes, mix the solution into a uniform milky solution; weigh 44g of bicycloalkenyl ester and 80g of toluene respectively, add them to a 500ml four-necked flask, install the stirrer, thermometer, Dropping funnel and water separator condenser. Stir and heat up to 70-80°C; start dropping the oxidant solution in the dropping funnel, maintain the system temperature at about 70-80°C, and complete the dropwise addition in 60-90 minutes; continue to react for 60 minutes. After standing still for 30 minutes, the lower organic phase was separated, and the upper aqueous layer was discarded.

[0029] The separated organic phase solution was added to a 250ml four-neck flask, and a stirrer, a thermometer, and a water condensing device were installed. Heating in an oil bath, the temp...

Embodiment 3

[0032] Take by weighing 80.0 g hydrogen peroxide (content is 15%) and 30.0g1,2 dichloroethanes, 2.5g catalyst heteropolyacid (composite heteropolyacid catalyst synthesized by 1mol tungstic acid and 9 molybdic acid); join in the single-necked flask, Install the stirrer, adjust the pH value to 2.4-3.0 with 0.5g-1.0 sodium hydrogen phosphate; stir for 60-90 minutes, and mix the solution into a uniform milky solution; weigh 44g of bicycloalkenyl ester, 1,2- Dichloroethane 80g, join in the 500ml four-necked flask, install stirrer, thermometer, dropping funnel and water separation condensing device. Stir and heat up to 60-70°C; start dropping the oxidant solution in the dropping funnel, maintain the system temperature at about 60-70°C, and complete the dropwise addition in 60-90 minutes; continue the reaction for 120 minutes. After standing still for 30 minutes, the lower organic phase was separated, and the upper aqueous layer was discarded.

[0033] The separated organic phase so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com