Resistance random memory based on columbium oxide film and preparation method thereof

A technology of random access memory and niobium oxide, which is applied in the field of memory, can solve the problems of guaranteeing the characteristics of stoichiometric devices, etc., and achieve the effects of large application value, long data retention time, excellent transition and memory characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

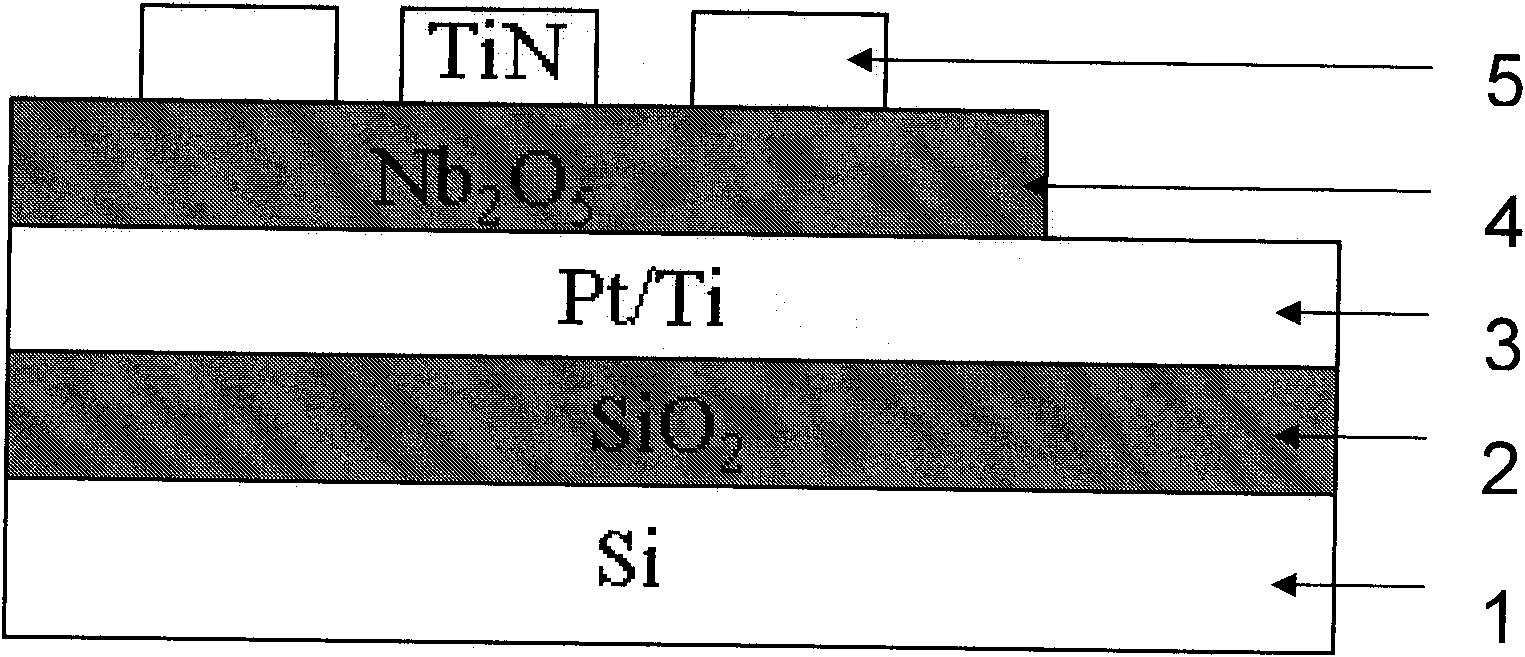

[0024] A silicon dioxide dielectric layer 1 is grown on a single crystal silicon 2 by means of thermal oxidation or chemical vapor deposition as a substrate. The oxidation temperature is 1100°C, the oxidation time is 5 minutes, and the thickness of the silicon dioxide layer is 150nm-200nm. Pt / Ti (80nm / 20nm) was prepared as the bottom electrode layer 3 by sputtering growth method. The sample was placed in the atomic layer deposition apparatus, and the wafer was heated to about 300°C before the first pulse in the pulse cycle. This temperature was maintained throughout the ALD growth period. The reaction chamber was brought to a pressure of about 1 Torr prior to the first pulse in the pulse cycle and maintained at this pressure throughout the process.

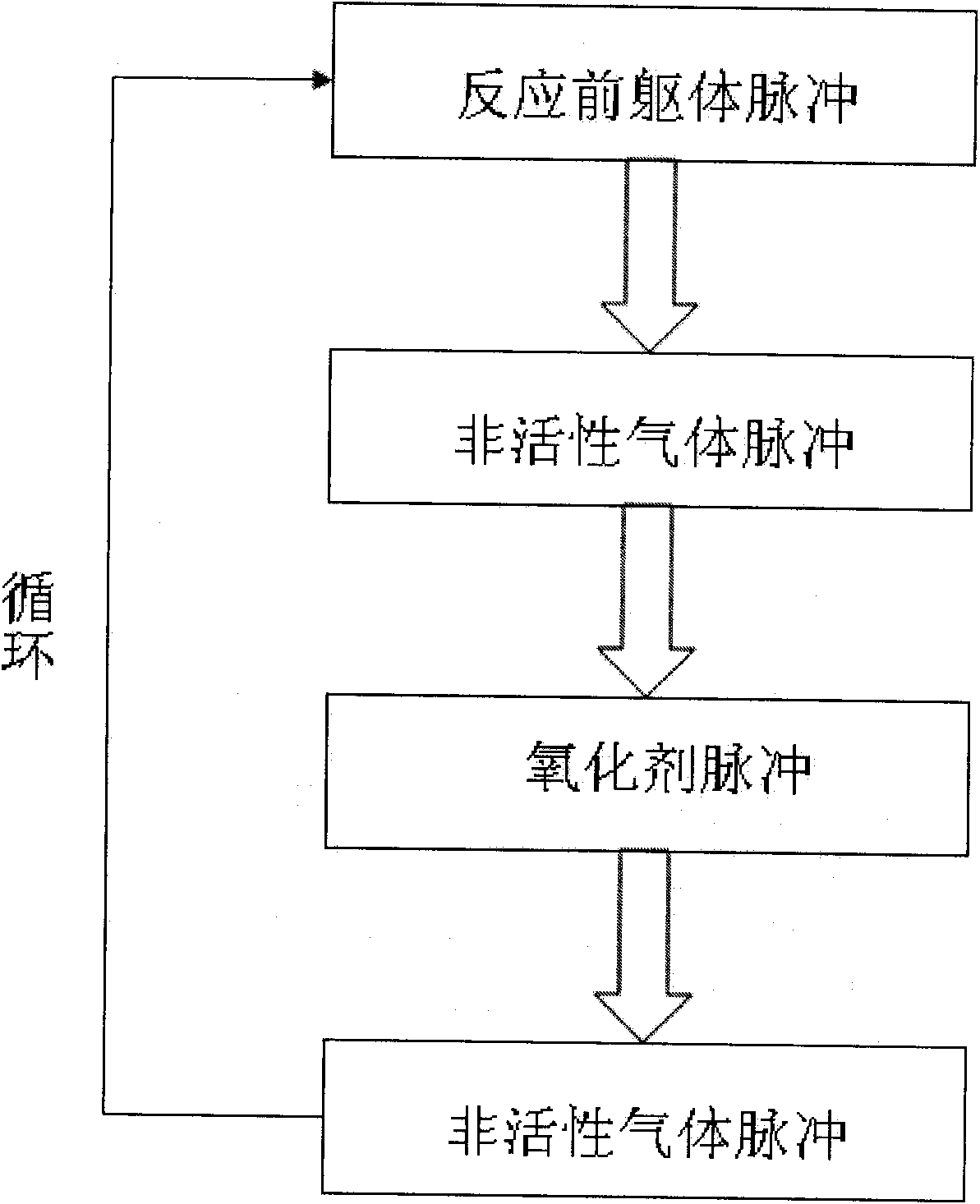

[0025] The pulse period is figure 2 shown in . The pulse cycle includes the following step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com