Method for processing silicon base material, article processed by the method, and processing apparatus

A processing method and processing device technology, applied in the field of processed products and processing devices of crystalline silicon substrates, can solve the problem of high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

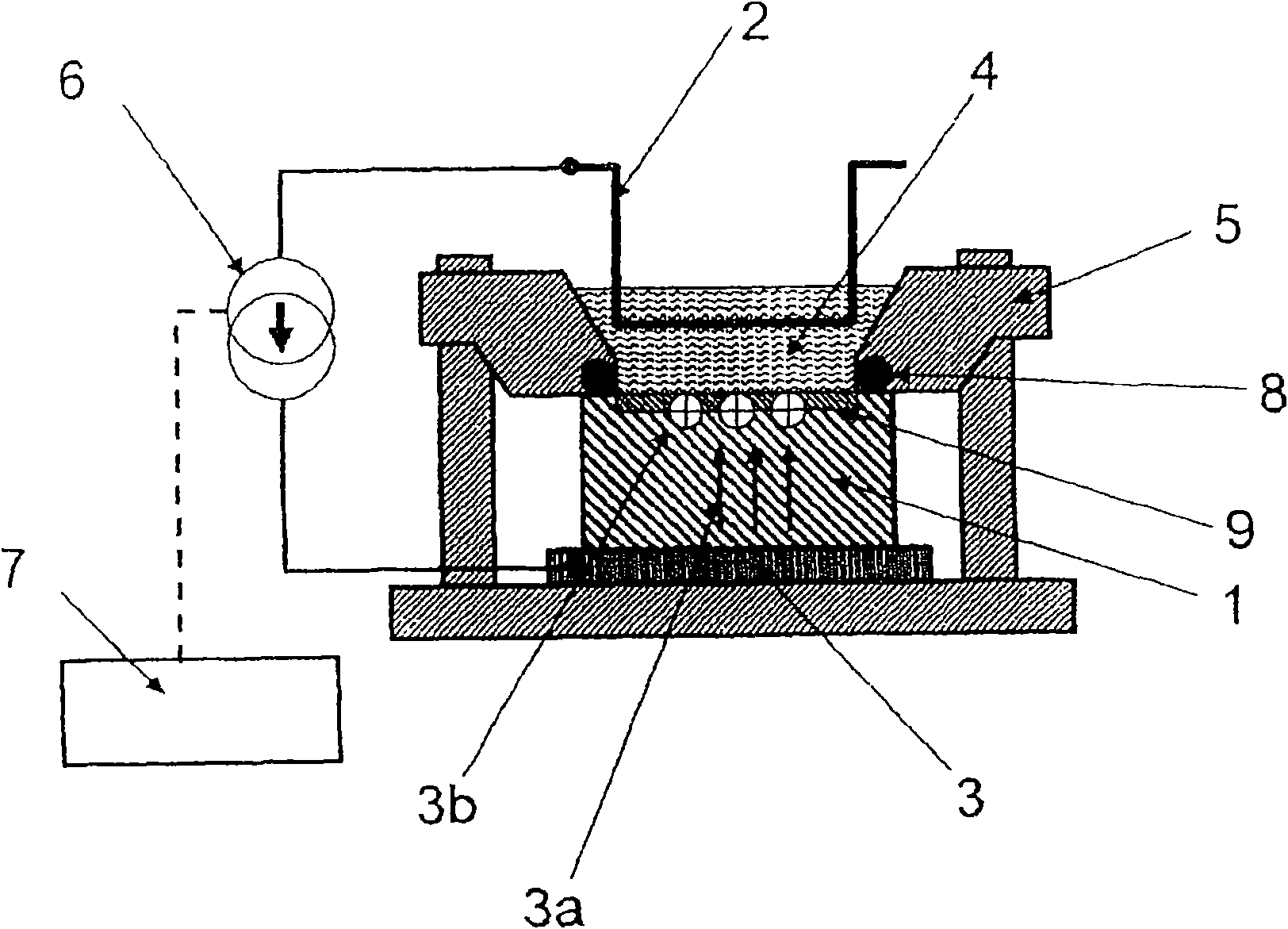

[0073] Figure 9 It is a cross-sectional view of an example of the present invention, showing the progress of anodic oxidation when micropores are formed on a silicon substrate in the order of A and B. use Figure 9 A shows the configuration of the device. 1 is a workpiece, which is a p-type silicon substrate having a resistivity of 1 Ω·cm, a thickness of 200 μm, and a square of 100 mm. The silicon substrate 1 is fixed to an electrolytic cell composed of a metal fixing jig and anode 3 and a support frame made of Teflon (registered trademark) through an organic conductive solid electrode (trade name: Nafion film) 3c with a thickness of about 200 μm. 5 on. A 1:1 mixed electrolyte solution 4 of 49% hydrofluoric acid aqueous solution and ethanol is held by the silicon substrate 1 and the electrolytic cell 5 . An O-ring seal 8 was provided on a portion of the lower surface of the support frame made of Teflon (registered trademark) that was in contact with the silicon substrate ...

Embodiment 2

[0084] Using Figure 10 In the processing of the silicon substrate in the configuration in which the electrolytic solution is supplied to the tip of the cathode described above, it has been demonstrated that the silicon substrate can be etched faithfully according to the shape of the cathode. If this property is utilized, the projected shape of the cathode can be arbitrarily shaped in advance, and the surface of the silicon substrate can be dug in an arbitrary shape. Figure 12 is an example of Figure 12 A is the plan view of the cathode, Figure 12 B is Figure 12 Elevation of section X-X' of A.

[0085] Figure 12 Among them, 2 is a protrusion processed into a height of about 5 mm and a cross-shaped projected shape on a plan view, and is installed on the base 2e. The material of the submount 2 e may be a metal other than platinum, but it is desirable that the surface thereof be covered with the insulating coating film 17 . In addition, the protruding portion 2 may be ...

Embodiment 3

[0088] elephant Figure 7 As already described, silicon ingot slicing can be performed by using the present invention. use Figure 13 Describe its implementation status. Figure 13 19 is the main drive roller, two 19a are the guide rollers of the wire, and 19b and 19c are respectively the sending and recovery bobbins of the wire. The platinum wire 2 is conveyed from the wire sending bobbin 19b, wound around the guide roller 19a and the main roller 19 several times, and then collected on the recovery bobbin 19c. A silicon ingot 1 is mounted on a waterproof anode 3 provided on the bottom of an electrolytic tank 5, and the electrolytic tank 5 is filled with an electrolytic solution 4 to such an extent that the silicon ingot is soaked. The main roller 19 is electrically connected to the cathode side of the power supply 6 , and the anode side of the power supply 6 is electrically connected to the bottom of the silicon ingot 1 through the waterproof anode 3 at the bottom of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com