Pitch water emulsion and preparation method thereof

A technology for asphalt emulsion and asphalt raw materials, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of insufficient stability and unsuitability of asphalt emulsion, and achieves low production cost, small median particle size, and high stability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] According to the preparation method of asphalt emulsion provided by the present invention, comprises the following steps:

[0024] (1) Raise the temperature of 45-70% by weight of asphalt raw material to 80-150°C, then add 0.01-2% by weight, preferably 0.05-1% by weight of additives, stir evenly, and heat it to 100-190°C; The additive is selected from one or more of organic acids, esters, alkali metal salts of organic acids, alkali metal salts of esters, preferably formic acid, acetic acid, oxalic acid, tartaric acid, citric acid, fatty acid C10-22, alkyl One or more of sulfuric acid ester C10-22, aromatic acid, cycloalkane carboxylic acid, sulfonic acid, and alkali metal salts of the above-mentioned various acids and esters, more preferably oxalic acid, benzoic acid, fatty acid C10-22, Naphthalene acid, petroleum sulfonic acid, alkyl phosphate, alkyl sulfate C10-22, and one or more of the alkali metal salts of the above-mentioned acids and esters;

[0025] (2) Mixing ...

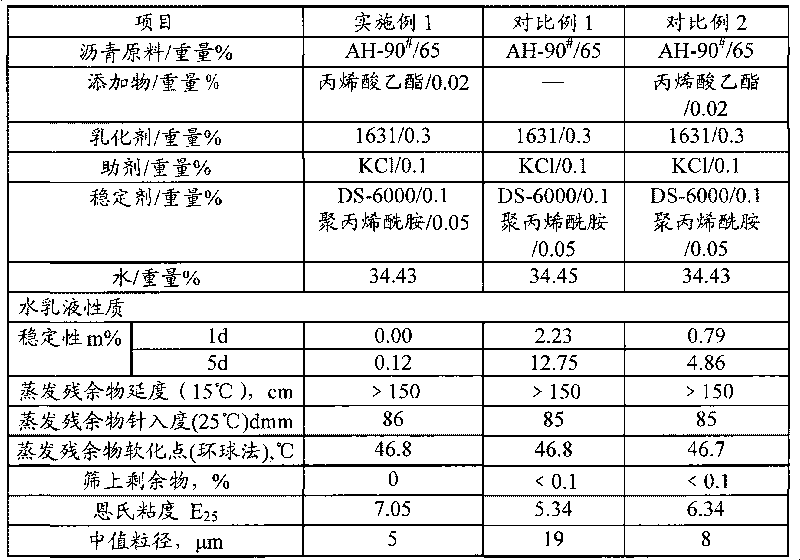

Embodiment 1

[0033] Heat 650g of asphalt raw material to a temperature of 110°C, add 0.2g of ethyl acrylate (produced by Beijing Dongfang Chemical Factory) under stirring, and then heat to 120°C. Mix 3g of cetyltrimethylammonium chloride (trade name 1631, produced by Shanghai Synthetic Detergent No. DS-6000, produced by Guangzhou Dongxing Fine Chemical Co., Ltd.), 0.5g polyacrylamide (Shanghai Shengzhong Fine Chemical Co., Ltd.) and 344.3g water were mixed, stirred to dissolve each component, and an emulsifier aqueous solution was obtained, and then heated to 70 ℃. The prepared asphalt containing ethyl acrylate and emulsifier aqueous solution were fully mixed with a colloid mill (type W4, produced by Wenzhou Colloid Mill Factory) to obtain an asphalt emulsion. The emulsion product has no skinning, and its properties are shown in Table 2.

[0034] The storage stability of this product meets the technical requirements of emulsified asphalt for roads. After being placed for one month, there ...

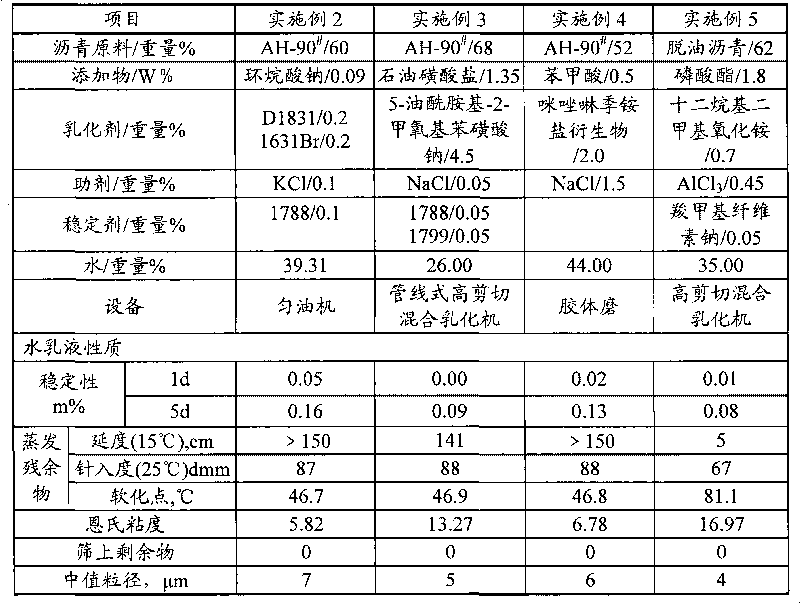

Embodiment 2

[0042] 600g of asphalt raw material was heated to a temperature of 100°C, mixed with 0.95g of sodium naphthenate (product of Shanghai Changfeng Chemical Factory) under stirring, and then heated to 140°C. 2g dioctadecyltrimethylammonium chloride (trade name D1831, produced by Shanghai Synthetic Detergent No. ) mixed with 1g Potassium Chloride (produced by Beijing Chemical Factory), 1g polyvinyl alcohol (trade name 1788, produced by Beijing Organic Chemical Factory), then add 393.1g water, stir to make each component dissolve, obtain emulsifier aqueous solution, and heat to a temperature of 80°C. The prepared asphalt containing sodium naphthenate and emulsifier aqueous solution were fully mixed with a homogenizer (model M50, produced by Shanghai Qidong Mixer Factory) to obtain an asphalt emulsion. This emulsion product has no skinning, and its properties are shown in Table 3 .

[0043] The product has been placed for one month without sedimentation and delamination. The storag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com