Plate lug connecting method used in process of assembling power soft-packed lithium-ion storage batteries

A connection method and flexible packaging technology, applied in battery pack components, secondary batteries, circuits, etc., can solve problems such as operator hazards, easy to cause virtual welding, complicated connections, etc., to facilitate operation and management, and prevent tab corrosion. , the effect of streamlining the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

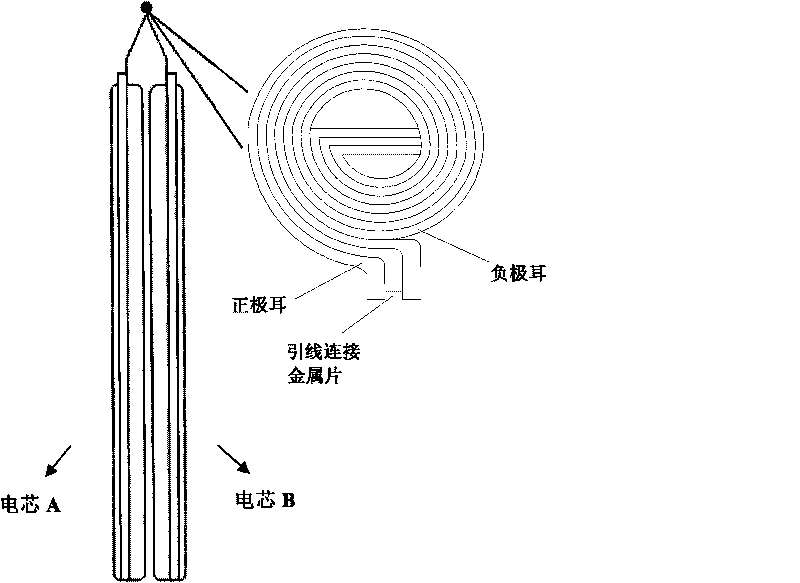

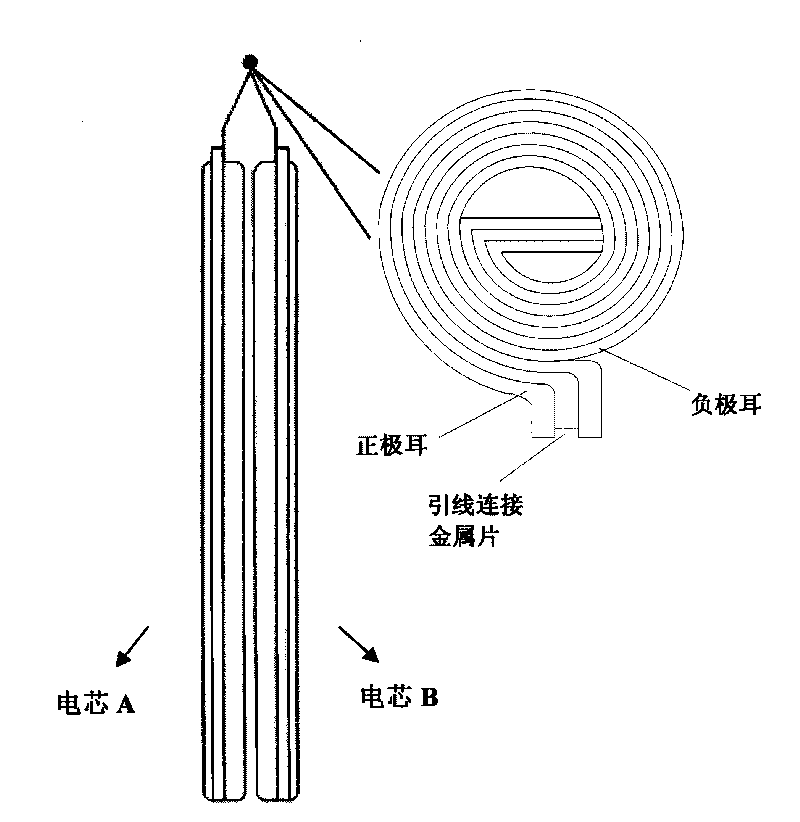

[0031] Such as figure 1 and figure 2 As shown, a tab connection method used in the assembly process of power-type soft-packaged lithium-ion batteries includes the following steps:

[0032] 1. According to the size of the tabs, design and manufacture suitable rolling needles in advance;

[0033] 2. Weld the leads of the circuit protection board with the prepared metal sheet;

[0034] 3. Pre-treat the tabs and the metal sheets connected by the lead wires: remove the dirt on the surface and the oxide film on the metal surface;

[0035] 4. Put the positive and negative tabs and the metal sheets connected by the lead wires together in a certain order, and fix them with the pre-made mold;

[0036] 5. Fix the winding needle of the winding equipment and the stacked pole pieces together, adjust the speed, and then start the winding equipment;

[0037] 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com