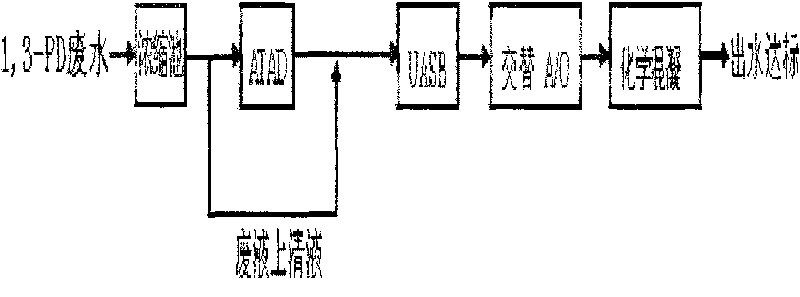

Biochemical comprehensive treatment method for 1, 3-propylene glycol fermentation organism waste water

A technology for fermenting microorganisms and comprehensive treatment, applied in the field of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

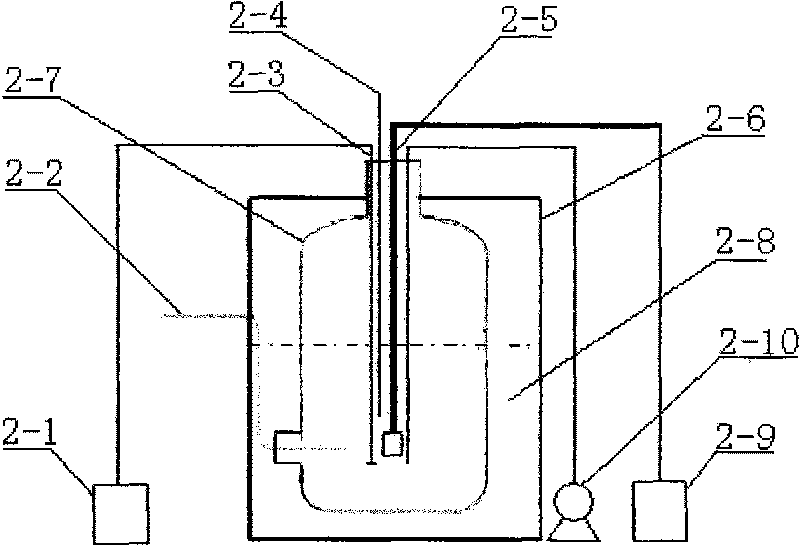

[0037] Embodiment 1 (ATAD processing)

[0038] Such as figure 2 shown by figure 1 The concentrated 1,3-PD fermented microbial wastewater of PetroChina Jilin Petrochemical Company is pumped into the reactor through the inlet pump 2-10 of the ATAD reactor 2-7 to carry out the automatic temperature-increasing degradation reaction of the fermented microorganism; the ATAD reactor is placed in In the water bath 2-8, the outside of the water bath is provided with an insulation layer 2-6; and the aeration rate of the aeration pipe 2-5 connected to it is adjusted by the aeration pump 2-9; the stirring device 2-1 is started to adjust the stirring The speed of the device 2-1 is stirred by the stirring paddle 2-3 to carry out the automatic temperature-increasing degradation reaction of the fermenting microorganism. A thermometer 2-4 is provided on the ATAD reactor; a sampling tube 2-2 is provided at the lower left side of the reactor. See Table 1 for the quality of wastewater entering...

Embodiment 2

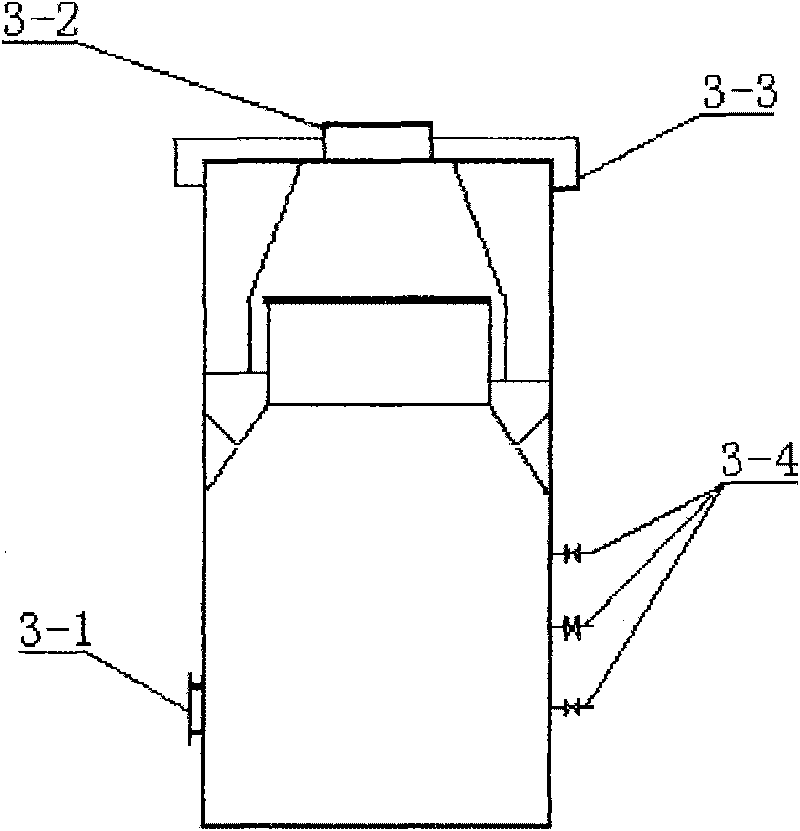

[0046] Embodiment 2 (UASB processing)

[0047] From image 3 It can be seen that a water inlet pipe 3-1 is provided at the lower part of the UASB reactor side, a biogas pipe 3-2 and a water outlet pipe 3-3 are provided at the top; three sampling pipes 3-4 are provided at the middle and lower part of the other side of the reactor. 10-30 parts by mass of waste liquid after ATAD treatment and 70-90 parts by mass of concentrated 1,3-propanediol fermentation microbial waste water are mixed (supernatant produced by waste water after ATAD treatment and 1,3-propanediol product The sum of liquid and waste liquids is 100 parts by mass, the waste water after the automatic temperature-increasing degradation treatment of fermentation microorganisms accounts for 10-30 parts, and the supernatant liquid waste liquid produced by 1,3-propanediol products accounts for 70-90 parts), at a temperature of At 30-60°C, it is sent to the UASB reactor, and the biogas generated during the experiment is ...

Embodiment 3

[0052] Embodiment 3 (alternate A / O processing)

[0053] From Figure 4 It can be seen that the outlet water of the UASB in the present invention enters the alternate anoxic / aerobic (alternative A / O) pool through the pipe 4-1. The alternate A / O process tank 4-4 of the device is provided with a variable wattage heating rod 4-5, and the bottom of the tank is provided with a microporous aeration head 4-6 connected with an ACO-280 electromagnetic air compressor 4-7 , the upper left of the A / O pool is provided with a water inlet pipe 4-1, and the upper right is provided with an outlet pipe 4-3. The stirring paddle installed in the A / O pool is driven by the JJ-1 type precision timing electric agitator 4-2 . The fermentation waste liquid of 1,3-PD product of PetroChina Jilin Petrochemical Company is treated by UASB process and then by alternate A / O process. See Table 3 for the water quality after alternate A / O process treatment and polyaluminum chloride coagulation treatment.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com