Method for detecting content of calcium element in calcium powder

A detection method and technology of calcium element, applied in material excitation analysis, thermal excitation analysis and other directions, can solve the problems of inability to guarantee the accuracy of the results, incomplete ashing, complicated processing methods, etc., and achieve low element loss and pollution rate, parallel Good results and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

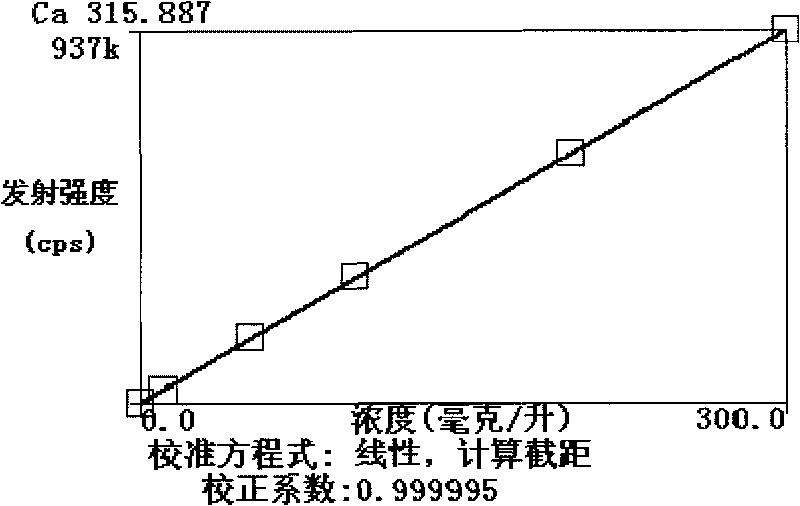

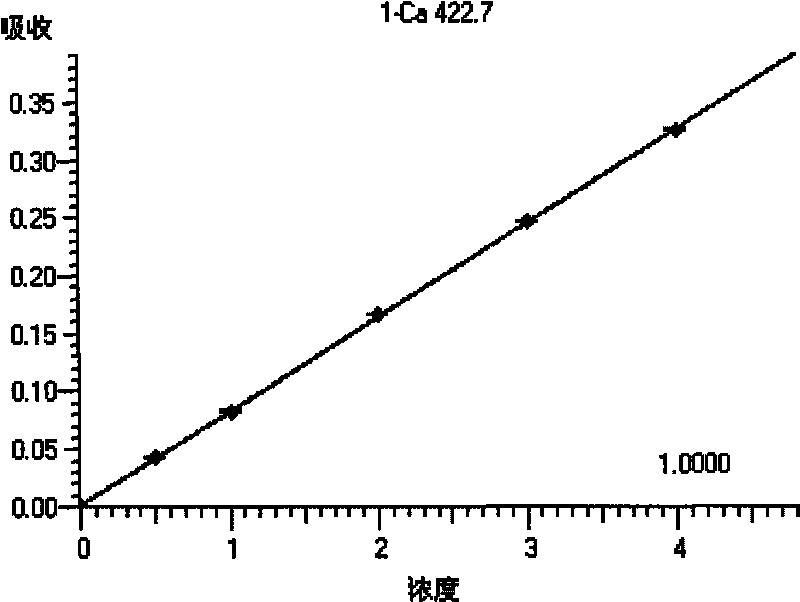

[0029] The drawing of embodiment 1 standard curve

[0030] 1. Preparation of standard solution

[0031] Prepare the standard solution of calcium: accurately draw the calcium standard stock solution (concentration 1000 μ g / ml, the single standard purchased by the National Standard Material Research Center) according to the volume listed in Table 1, in the 50ml volumetric flask, use 2% hydrochloric acid to make the volume accurately, Prepare a standard solution and mix well. The flame configuration standard solution is to make the standard stock solution into a 50ug / ml intermediate solution, and then take the intermediate solution to configure a series of solutions. Get the final standard series solutions, transfer them to polyethylene bottles, and store them in a refrigerator at 2-6°C in the dark for 2 weeks.

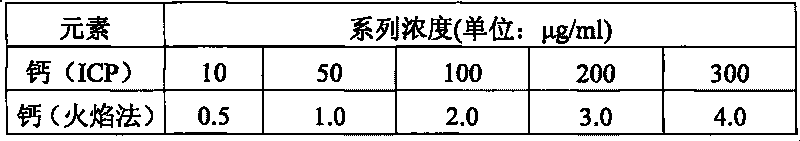

[0032] Table 1 The amount of stock solution required to prepare the standard series of solutions (unit: ml)

[0033]

[0034] The converted concentration is shown ...

Embodiment 2

[0054] The detection of calcium content in embodiment 2 calcium powder

[0055] Methods: The OPtima5300DV inductively coupled plasma optical emission spectrometer (ICP-OES) produced by Perkin-Elmer, USA was used to determine the calcium element in the calcium powder, and the Hitachi Z-2000 flame atomic absorption spectrophotometer was used to detect the calcium element content in the calcium powder.

[0056] Detection steps:

[0057] 1. Instrument preparation:

[0058] (1) Turn on the host and operating software, adjust the instrument to the best state, turn on the argon gas and water cooling cycle, and preheat for four hours.

[0059] (2) Check the water seal, install the hollow cathode lamp, open the operating software and the host, adjust the instrument to the best state, and preheat. After the instrument is preheated, turn on the water-cooling cycle, turn on the acetylene gas switch, and ignite the test sample.

[0060]2. Preparation of samples: Calcium powder was weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com