Preparation method of multi-pore canal nuclear shell type magnet gold compound nano-particle

A technology of composite nanoparticles and composite nanomaterials, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of poor chemical stability of magnetic nanoparticles, easy to be oxidized or agglomerated, unfavorable recoupling of biomolecules, etc. To achieve the effect of avoiding severe decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a method for preparing porous core-shell magnetic gold composite nanoparticles, which mainly includes the following steps:

[0019] (1) Ultrasonic disperse the hydrophilic magnetic nanoparticles in the sugar solution, transfer to a reaction kettle, and react at 160-200° C. for 4-8 hours. After the reaction, the homogeneously nucleated carbon spheres were removed by magnetic separation, and the obtained carbon spheres coated with magnetic particles were washed three times with deionized water, and then dried in a vacuum oven at 60°C for 24 hours.

[0020] (2) Take 100 mg of carbon spheres coated with magnetic cores, disperse them ultrasonically in secondary water at 0.5-20 mg / mL, and add dropwise 10-500 micrograms of chloroauric acid solution with a mass fraction of 1%-5% after reflux for 5 min. liter, continue to reflux for 20-120min, the color of the solution gradually changes from yellowish brown to red, and a magnetic composite nanomaterial wit...

Embodiment 1

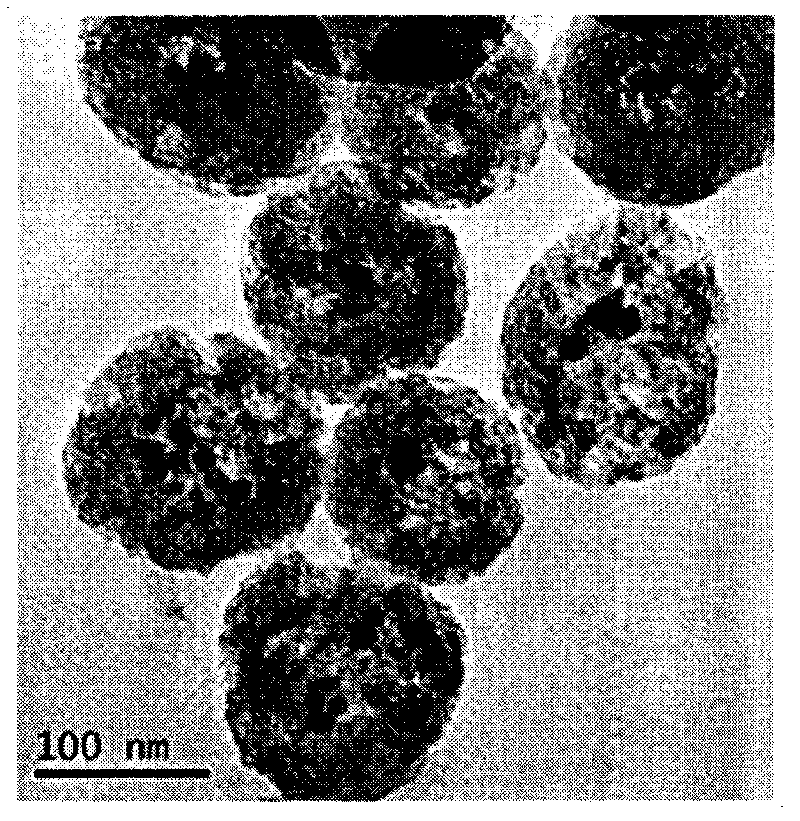

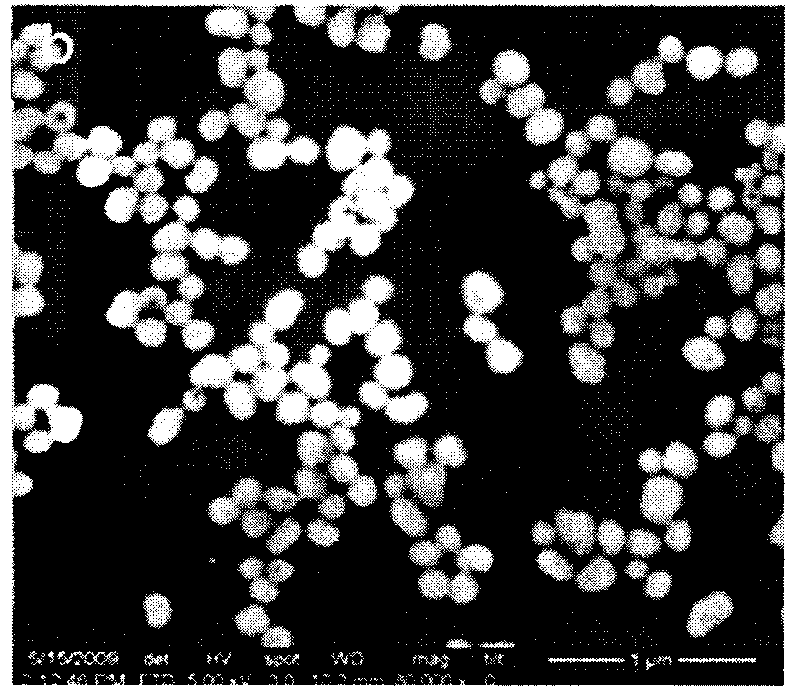

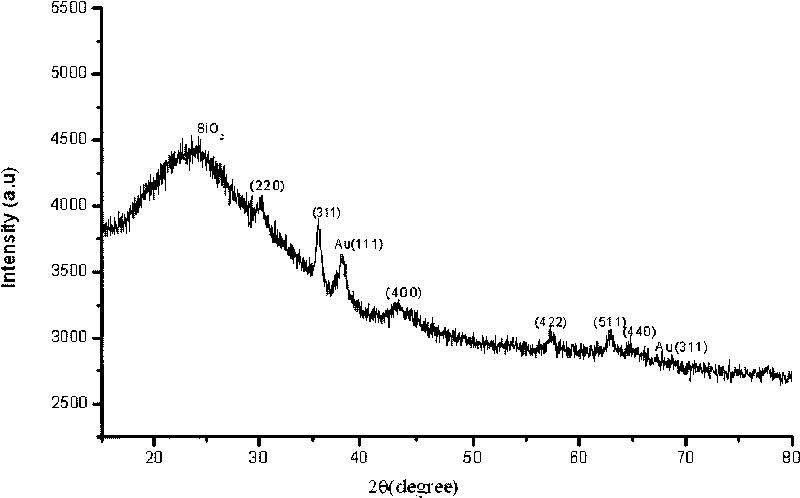

[0032] Weigh 100mg of Fe with an average particle size of 10nm 3 o 4 Nanoparticles were ultrasonically dispersed in 30ml of an aqueous solution containing 0.5g of glucose, and the dispersion was transferred to a reaction kettle and reacted at 170°C for 4h. After the reaction, cool to room temperature, and remove the homogeneous nucleated carbon spheres by magnetic separation to obtain carbon spheres containing magnetic particles. The thickness of the carbon layer is about 1nm. Wash it three times with deionized water and place it in a vacuum drying oven. Dry at 60°C for 24h. Take 100 mg of carbon spheres containing magnetic cores in the resulting mixture, ultrasonically disperse them in 20 ml of water at a rate of 5 mg / mL, add 500 microliters of chloroauric acid solution with a mass fraction of 1% after reflux for 5 minutes, and continue to reflux for 20 minutes. The color of the solution changes from yellowish brown to is red, and the magnetic composite nanomaterial with go...

Embodiment 2

[0035] Weigh 100mg of Fe with an average particle size of 10nm 3 o 4 Nanoparticles were ultrasonically dispersed in 30ml of an aqueous solution containing 0.5g of glucose, and the dispersion was transferred to a reaction kettle and reacted at 170°C for 4h. After the reaction, cool to room temperature, and remove the homogeneous nucleated carbon spheres by magnetic separation to obtain carbon spheres containing magnetic particles. The thickness of the carbon layer is about 1nm. Wash it three times with deionized water and place it in a vacuum drying oven. Dry at 60°C for 24h. Take 100 mg of carbon spheres containing magnetic cores in the resulting mixture, ultrasonically disperse them in 20 ml of water at a rate of 5 mg / mL, add 300 microliters of chloroauric acid solution with a mass fraction of 1% after reflux for 5 minutes, and continue to reflux for 20 minutes. The color of the solution changes from yellowish brown to is red, and the magnetic composite nanomaterial with go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com