A method of preparing wear-resistant ceramic lining board by active brazing method

A technology of wear-resistant ceramics and active brazing, which is applied in the field of preparation of wear-resistant ceramic lining boards, which can solve the problems of easy aging of rubber materials, easy falling off of ceramics, and low bonding strength, so as to achieve not easy falling off, greater bonding strength, and improved strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

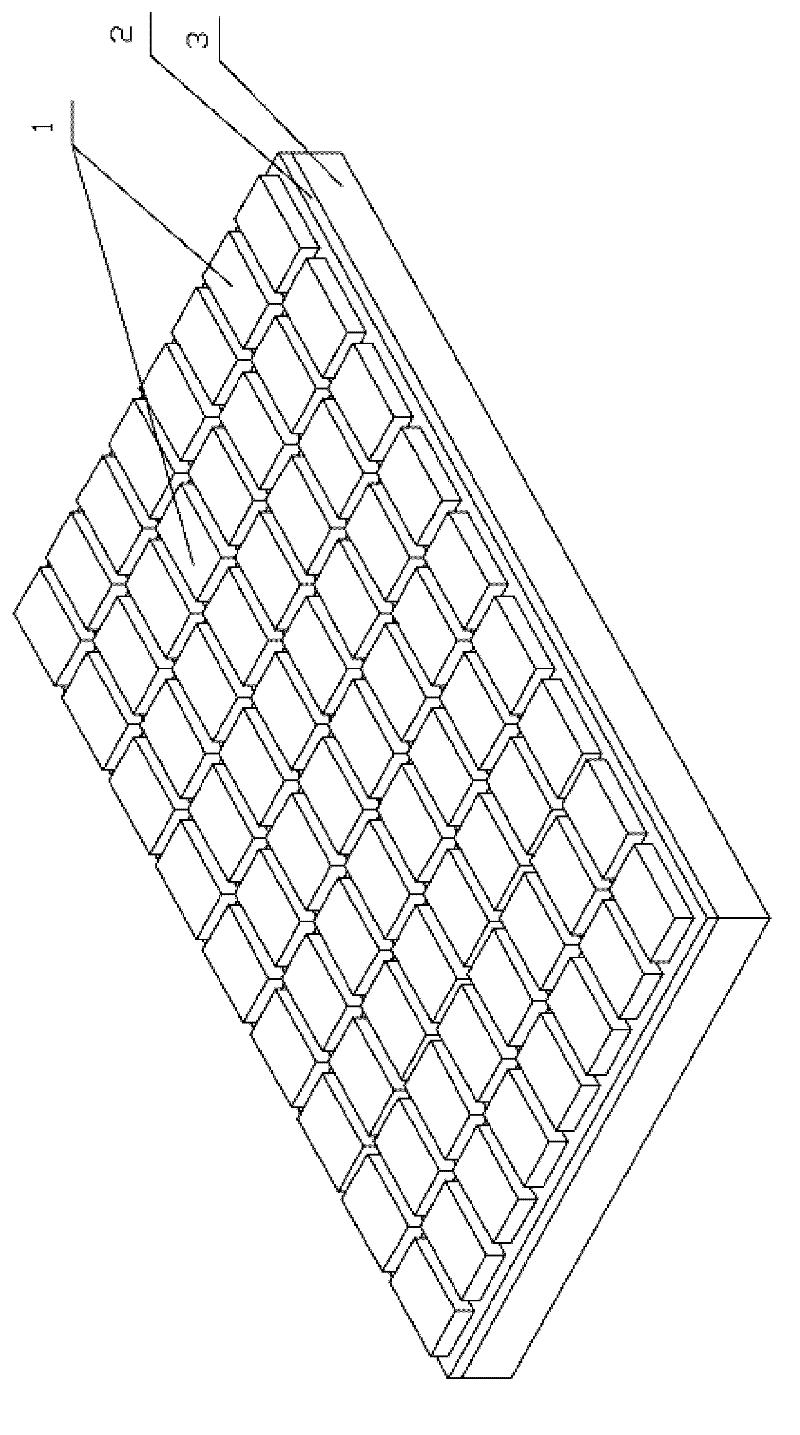

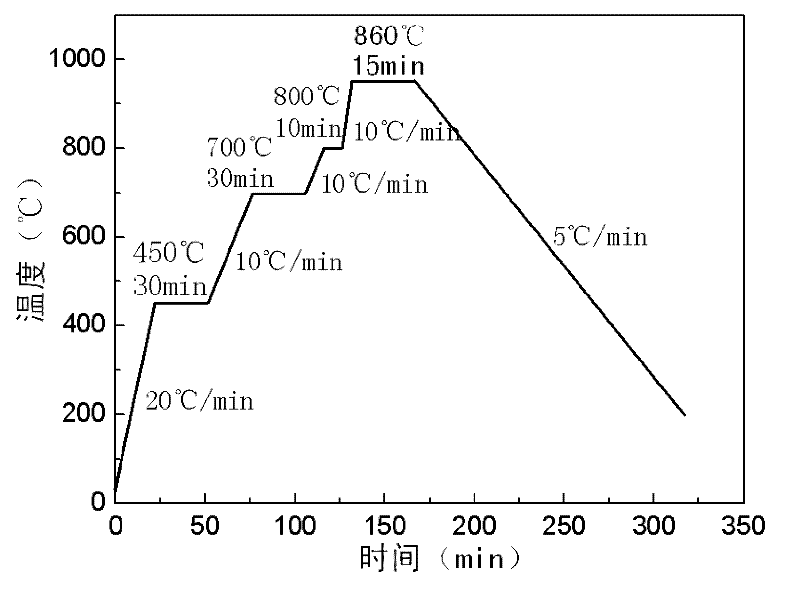

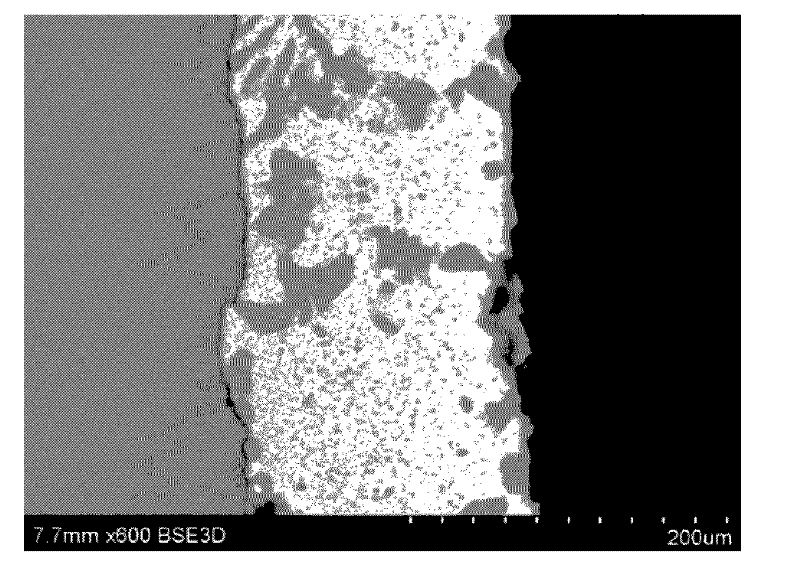

[0018] Specific embodiment one: the method for preparing the wear-resistant ceramic liner with the active brazing method in this embodiment is realized by the following method: one, by mass fraction, 60%~80% Ag powder, 18%~35% Cu Powder and 1%~5% TiH 2 Put the powder into a stainless steel tank after mixing, then add acetone to make the acetone 1-5cm higher than the mixed powder, then fill the stainless steel tank with inert gas, seal the stainless steel tank, and then ball mill for 25-30 hours, then mix the powder after ball milling Powder and binder are mixed to obtain active metal paste solder, wherein the mass ratio of ball to material is 20:1, the mass ratio of mixed powder to binder is 20:1, and the mass fraction of binder is from 0.8% to 1.2 % glycerol, 95% to 97% distilled water and 2% to 4% hydroxyethyl cellulose; 2. Clean the surface of the ceramic block and the low-alloy high-strength structural steel plate respectively, then dry it naturally, and then put the ceram...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, 70% Ag powder, 27% Cu powder and 3% TiH 2 The powder is mixed and placed in a stainless steel tank. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the inert gas in step 1 is argon or helium. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com