Probiotic tablet and preparation method thereof

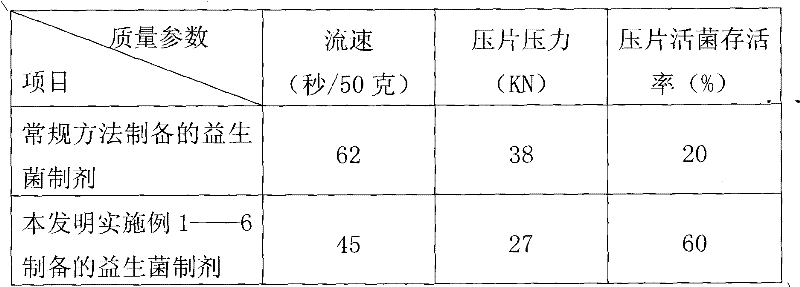

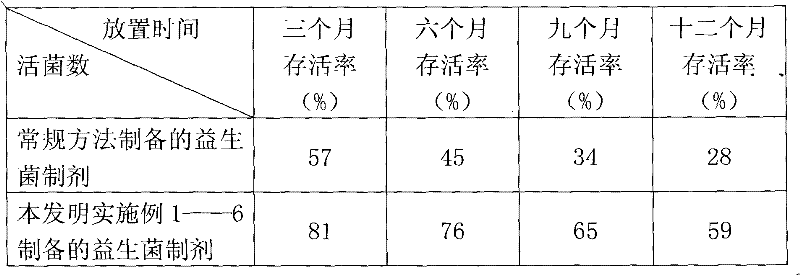

A probiotic tablet and tablet compression technology, which is applied in pill delivery, pharmaceutical formula, medical raw materials derived from bacteria, etc., can solve problems such as the inability of direct granulation of probiotic powder, poor fluidity of direct compression of powder, and low survival rate of viable bacteria, etc. problem, to achieve the effect of low cost, good reproducibility, and high survival rate of live bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Using dry granulation technology and tabletting technology, granules are prepared from auxiliary materials such as glucose, lactose, microcrystalline cellulose, and skimmed milk powder, and then mixed with active ingredients probiotic powder and magnesium stearate for tabletting, and finally probiotics are obtained tablet.

[0021] Its production method comprises the following steps:

[0022] (1) Preparation of pharmaceutical excipients: prepared in parts by weight, including 20 parts of glucose, 40 parts of lactose, 10 parts of microcrystalline cellulose, 10 parts of skimmed milk powder, 5 parts of sodium carboxymethyl starch, 1 part of sucrose, and 1 part of citric acid , 0.01 part of magnesium stearate;

[0023] (2) Dry granulation: After mixing the pharmaceutical excipients, add them to a dry granulator for granulation, and collect granules of 10-60 mesh for raw material mixing;

[0024] (3) Mixing of raw materials: the prepared granules and probiotic powder are m...

Embodiment 2

[0027] Using dry granulation technology and tabletting technology, granules are prepared from auxiliary materials such as glucose, lactose, microcrystalline cellulose, and skimmed milk powder, and then mixed with active ingredients probiotic powder and magnesium stearate for tabletting, and finally probiotics are obtained tablet.

[0028] Its production method comprises the following steps:

[0029] (1) Preparation of pharmaceutical excipients: prepared in parts by weight, including 40 parts of glucose, 20 parts of lactose, 30 parts of microcrystalline cellulose, 30 parts of skimmed milk powder, 15 parts of sodium carboxymethyl starch, 10 parts of sucrose, and 10 parts of citric acid , 1 part of magnesium stearate;

[0030] (2) Dry granulation: After mixing the pharmaceutical excipients, add them to a dry granulator for granulation, and collect 60-120 mesh granules for raw material mixing;

[0031] (3) Mixing of raw materials: the prepared granules and probiotic powder are m...

Embodiment 3

[0034] Using dry granulation technology and tabletting technology, granules are prepared from auxiliary materials such as glucose, lactose, microcrystalline cellulose, and skimmed milk powder, and then mixed with active ingredients probiotic powder and magnesium stearate for tabletting, and finally probiotics are obtained tablet.

[0035] Its production method comprises the following steps:

[0036] (1) Preparation of pharmaceutical excipients: prepared in parts by weight, including 25 parts of glucose, 25 parts of lactose, 20 parts of microcrystalline cellulose, 20 parts of skimmed milk powder, 10 parts of sodium carboxymethyl starch, 5 parts of sucrose, and 5 parts of citric acid , 0.5 parts of magnesium stearate;

[0037] (2) Dry granulation: After mixing the pharmaceutical excipients, add them to a dry granulator for granulation, and collect 10-30 mesh granules for raw material mixing;

[0038] (3) Mixing of raw materials: the prepared granules and probiotic powder are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com