Tetramethyl-diphenol type polyarylether ketone (polyarylether sulphone) containing bromine at phenmethyl position and preparation method thereof

A tetramethylbiphenol type, polyaryletherketone technology, applied in the field of brominated polyaryletherketone/polyarylethersulfone and its preparation, can solve the problems of high melting point, harsh processing conditions and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

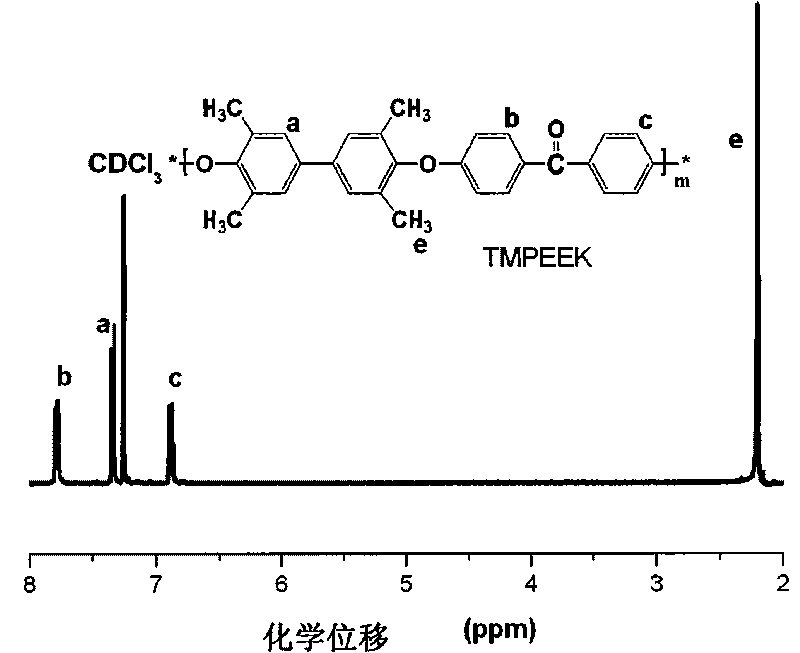

Embodiment 1

[0034] In a 500ml three-neck flask equipped with a stirrer, air duct, water separator and condenser, add 0.02mol 3,3',5,5'-tetramethylbiquinone, 0.02mol difluorobenzophenone, 0.024 mol potassium carbonate, under a nitrogen atmosphere, use 65ml sulfolane as a solvent, 30ml toluene as a water-carrying agent, heat up to 140°C and react with water for 3 hours, then distill off the toluene, and then heat up to 180°C for 4 hours. After the reaction, the mixed solution was poured into deionized water to obtain a white strip polymer. Break the strip polymer into powder with a tissue grinder, boil and wash with acetone several times to remove the solvent, and repeatedly boil and wash with distilled water to remove salts, and then put it in an oven for 24 hours at 60°C to obtain a white powdery solid 7.78 g, is tetramethylbiphenol-type polyaryletherketone, and its yield is 90.8%.

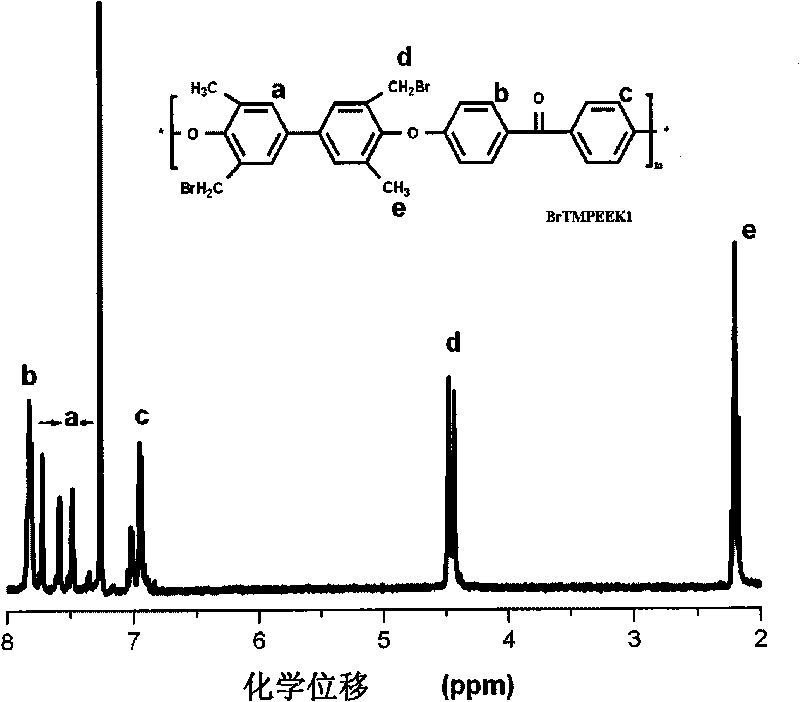

[0035] Take by weighing 4.2g of tetramethylbiphenol type polyaryletherketone of above-mentioned gained, N...

Embodiment 2

[0040] According to the method described in Example 1, tetramethylbiphenol-type polyaryletherketone was prepared.

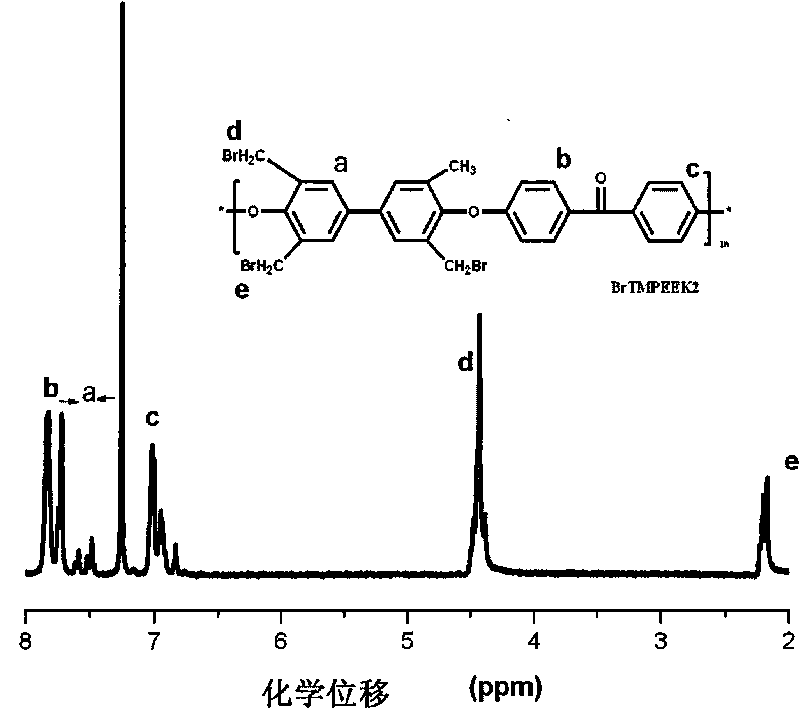

[0041] Take by weighing 4.2g of the above-mentioned tetramethylbiphenol type polyaryletherketone, N-bromosuccinimide (NBS) 6.4g (0.04mol), benzoyl peroxide (BPO) 0.05g, and 100ml of carbon tetrachloride was sequentially added into a 250ml three-necked bottle equipped with an electric stirrer, an air duct, and a reflux device, and reacted at 76°C for 2 hours under a nitrogen atmosphere. After the reaction, the mixed solution was poured into an aqueous solution of ethanol with a volume concentration of 50% to obtain an orange-yellow precipitate; Boil for one hour, then filter while hot, repeat 5 times; then boil with water for half an hour, then filter while hot, repeat 5 times; Tetramethylbiphenol-type polyaryletherketone BrTMPEEK2 (6.12g) containing bromine in the benzyl position of three structural units with a yield of 92.7%.

[0042] Table 2 provides the che...

Embodiment 3

[0046] In a 500ml three-necked flask equipped with a stirrer, an air duct, a water separator and a condenser, add 0.02mol of 3,3',5,5'-tetramethylbiphenol, 0.02mol of 4,4'- Dichlorodiphenyl sulfone, 0.024mol potassium carbonate, under nitrogen atmosphere, take sulfolane as solvent, 30ml toluene as water-carrying agent, reaction system solid content is 30% (wt), be warming up to 140 ℃ of band water reaction 3 hours, then The toluene was distilled off, and then the temperature was raised to 200°C for 7 hours of reaction. After the reaction, the mixed solution was poured into deionized water to obtain white strips. Use a tissue grinder to crush the strip-shaped polymer into powder, boil and wash it with acetone several times to remove the solvent, and wash it repeatedly with distilled water to remove the salt, then put it in an oven and dry it at 60°C for 24 hours to obtain a white powder 9.63 g of the solid is tetramethylbiphenol type polyaryl ether sulfone, and its yield is 94...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com