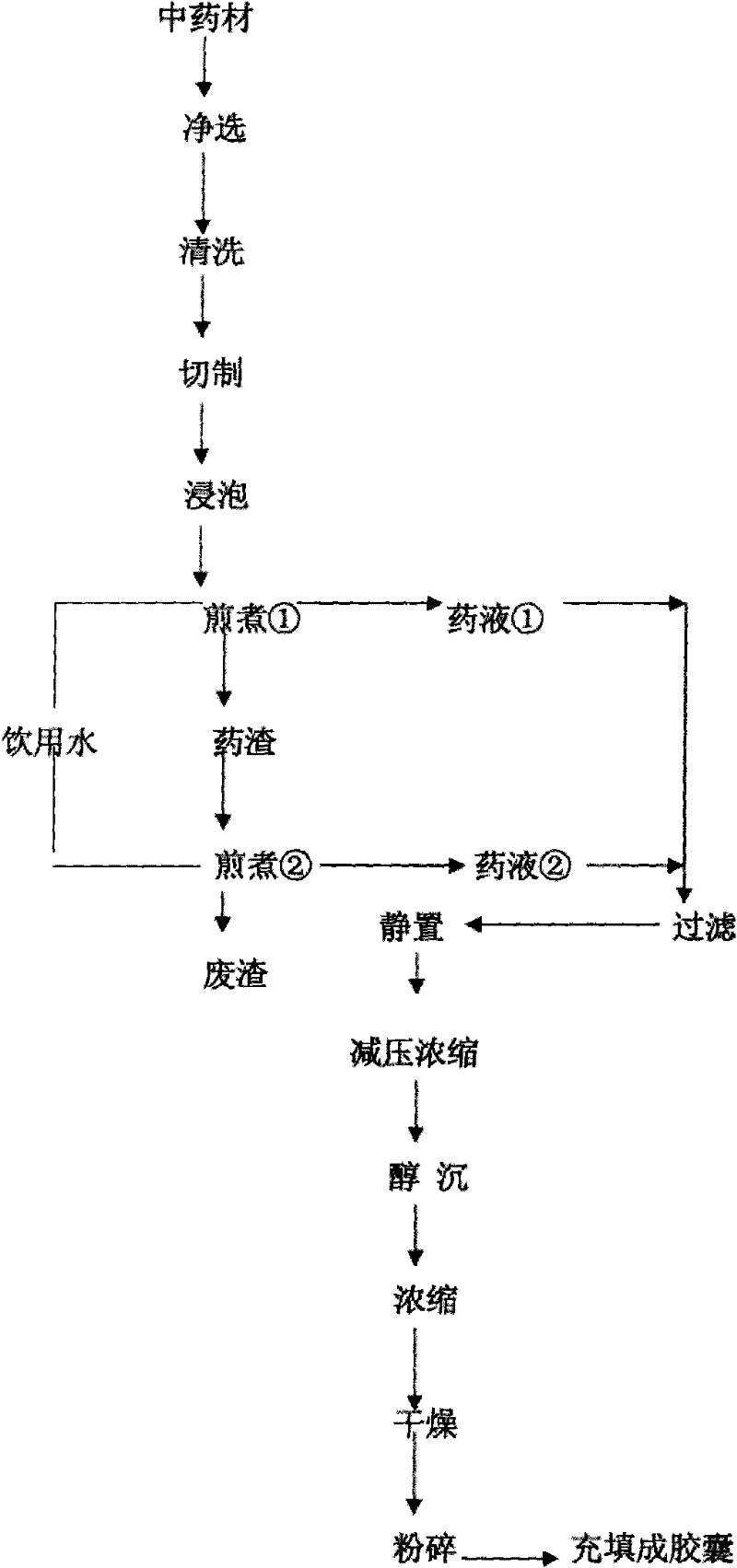

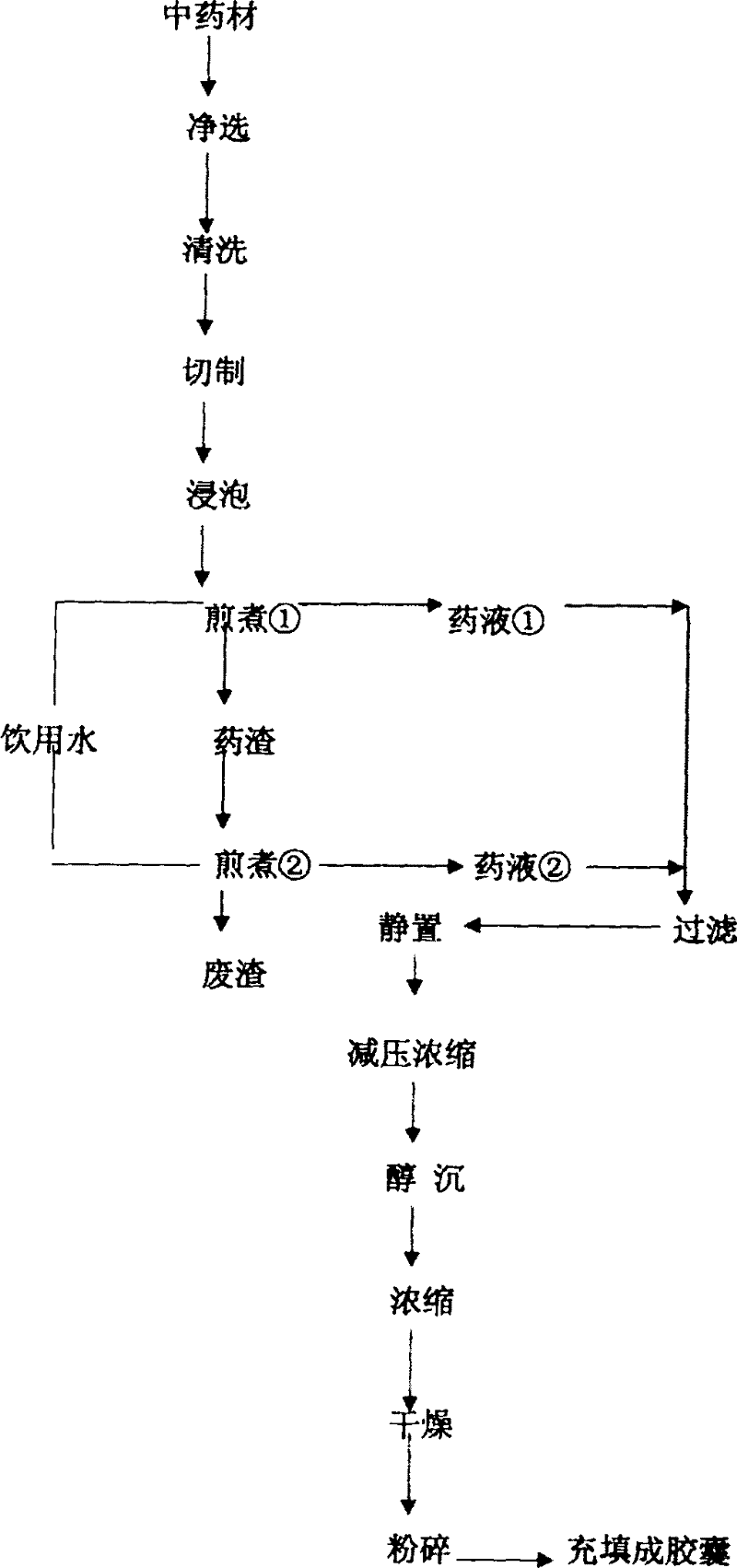

Preparation method of guava leaf extract and traditional Chinese medicine preparation thereof

A guava leaf and extract technology, applied in the field of preparation of guava leaf extract, can solve the problems of unacceptable industrial production, difficult control of production links, large ethanol consumption, etc., and achieve simple operation equipment and process flow, The effect of direct curative effect and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 (preliminary test)

[0037] Grind 64kg of guava leaf medicinal material, pack part of the fine powder into bags, put into a decoction tank, add 640kg of drinking water, heat to boil, keep warm and soak until the next day, heat and decoct for 3 hours, add 600kg of water for the second decoction, and decoct After 3 hours, the decoction liquid was combined with three effects and concentrated to a density of 1.15g / mL and a weight of about 15kg. Then, 4 times the amount of 95% ethanol was added to about 60kg. The ethanol concentration at this time was measured to be 75%. Clear liquid, the concentration of ethanol at this time is about 88%, concentrated in vacuum to a density of 1.30g / mL, and 2.5kg of extract is collected, and the precipitate is alcohol-precipitated once according to the above method, and a total of about 1.5kg of extract is collected, dried , vacuum-drying the above two received extracts at 80°C for about 4 hours (part of the baking tray is cove...

Embodiment 2

[0040] Embodiment 2 (on the basis of preliminary test, alcohol precipitation process is improved)

[0041]Put 60.0kg of guava leaves into the traditional Chinese medicine extraction tank, add about 600kg of water, turn on the steam valve and heat to 80°C, soak for 14 hours. Heat and decoct until boiling and keep the boiling time for 3 hours, pour the decoction liquid into the three-effect concentration tank; add about 600kg of water to the second slag, decoct until boiling and keep the boiling time for 3 hours, filter the feed liquid to the concentration tank to concentrate When the density is 1.18g / mL, the ointment is collected, and the weight is about 40kg.

[0042] One-time alcohol precipitation: add 40kg extract into the alcohol precipitation tank, heat and stir, add 82kg of 95% ethanol at the same time, continue stirring, close the steam valve, and open the jacket cooling water, continue stirring for about 20 minutes, measure the alcohol precipitation supernatant Concent...

Embodiment 3

[0047] Embodiment 3 (scale-up test, further confirms the feasibility of technique)

[0048] 1. Put 200kg of guava leaves into the extraction tank, add 2 tons of water, heat to 80°C and soak for 14 hours, decoct for 3 hours, filter out the decoction to the concentration tank, add 2 tons of water to the second residue and decoct for 3 hours, three Efficiently concentrate until the density is 1.18g / mL to collect the extract, and the weight of the extract is 105kg.

[0049] 2. Alcohol precipitation process

[0050] (1) Primary alcohol precipitation: first add about 50kg of 92% ethanol to the alcohol precipitation tank, then add the three-effect extract into the alcohol precipitation tank at one time, add ethanol while stirring, pass cooling water, and add 92% in total About 210kg of ethanol, after adding, continue to stir, vacuum backflush, measure the ethanol concentration of the ethanol sink solution to be about 58%, let it stand for 40 hours, pump the supernatant, and measure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com