Environment-friendly antibiosis glazing agent and preparation method thereof

An environmentally friendly, fungicide technology, applied in the fields of botanical equipment and methods, chemical instruments and methods, biocides, etc., can solve the problems of environmental and human harm, pungent odor, poor sterilization effect, etc. Good bacteriostatic effect, convenient storage, and the effect of preventing the growth and spread of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

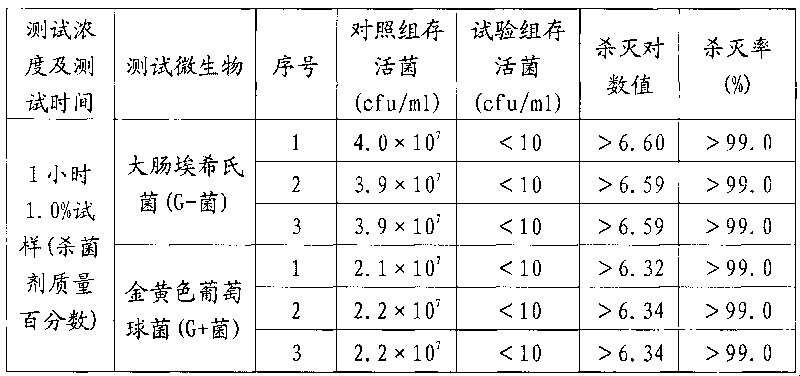

Image

Examples

Embodiment approach 1

[0040] Put 7.0 parts of olive oil and 3.5 parts of wax agent (by weight ratio: beeswax: carnauba wax = 1:6, uniform mixture) into the reactor according to the weight ratio, and stir to dissolve at 400r / min; Under the rotation speed of 800r / min, sequentially add 6.0 parts of silicone oil (parts by weight: medical dimethyl silicone oil: aminosiloxane = 5:1, uniform mixture) 6.0 parts, Span-60 2.0 parts, and deionized water 1.0 parts , Stir for 20 minutes; add 5.0 parts of surfactant (parts by weight: alkyl polyglycoside: Tween-80=3:2, uniform mixture), bactericide (parts by weight: water-soluble chitosan: Nano-silver aqueous solution=3:5, uniform mixture) 0.8 part, sorbic acid 0.1 part, heated and dissolved in 6.0 parts deionized water at 50°C to make a premixed liquid; at 1000r / min, slowly add the premixed liquid into the reactor Add the remaining deionized water at a speed of 1400r / min and stir for 50min; cool to room temperature, add 0.4 part of pineapple flavor and 1.0 part o...

Embodiment approach 2

[0042] Put 6.0 parts of oleic acid and 3.0 parts of wax agent (by weight ratio: beeswax: carnauba wax = 1:2, uniform mixture) into the reaction kettle according to the proportion by weight, and stir to dissolve at 500r / min; At 800r / min, add 7.0 parts of silicone oil (parts by weight ratio: medical dimethyl silicone oil: aminosiloxane = 6:1, uniform mixture), 3.0 parts of fatty alcohol polyoxyethylene ether, and deionized water. 1.5 parts, stirring for 25 minutes; add 4.0 parts of surfactant (parts by weight ratio: Tween-80: Span-60 = 6:1, uniform mixture), and bactericide (parts by weight ratio: neogermide: nano silver Aqueous solution=3:7, homogeneous mixture) 0.8 part of sodium benzoate, 0.2 part of sodium benzoate, heated and dissolved in 6.0 parts of deionized water at 50°C to make a premixed solution; at a rotation speed of 1000r / min, the premixed solution is slowly added to the reactor, Stir for 30min; add the remaining deionized water at a speed of 1500r / min and stir for...

Embodiment approach 3

[0044] Put 7.5 parts of coconut oil and 4.0 parts of wax agent (by weight ratio: beeswax: carnauba wax = 1:4, uniform mixture) into the reaction kettle according to the proportion by weight, and stir and dissolve at 500r / min; At a speed of 900r / min, add 5.0 parts of silicone oil (parts by weight: medical dimethyl silicone oil: aminosiloxane = 4:1, uniform mixture), 3.0 parts of fatty alcohol polyoxyethylene ether, and deionized water. 2.0 parts, stirring for 20 minutes; add 5.0 parts of surfactant (parts by weight ratio: alkyl polyglycoside: Tween-80 = 3:1, uniform mixture), bactericide (parts by weight ratio: neogermide: water-soluble Chitosan=2:1, homogeneous mixture) 1.0 part, sorbic acid 0.2 part, heated and dissolved in 8.0 parts of deionized water at 50°C to make a premixed liquid; at a speed of 1000r / min, slowly add the premixed liquid to the reactor Add the remaining deionized water at a speed of 1300r / min and stir for 50min; cool to room temperature, add 0.3 part of st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Saponification value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com