Solution temperature and humidity adjustment air treatment system

An air treatment system, temperature and humidity adjustment technology, applied in air conditioning systems, ventilation systems, shielding with air flow, etc., can solve the problem of high energy consumption, damage to the thermal comfort of air-conditioned rooms, and easy breeding of bacteria and mold, etc. problem, to achieve the effect of large mass transfer driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

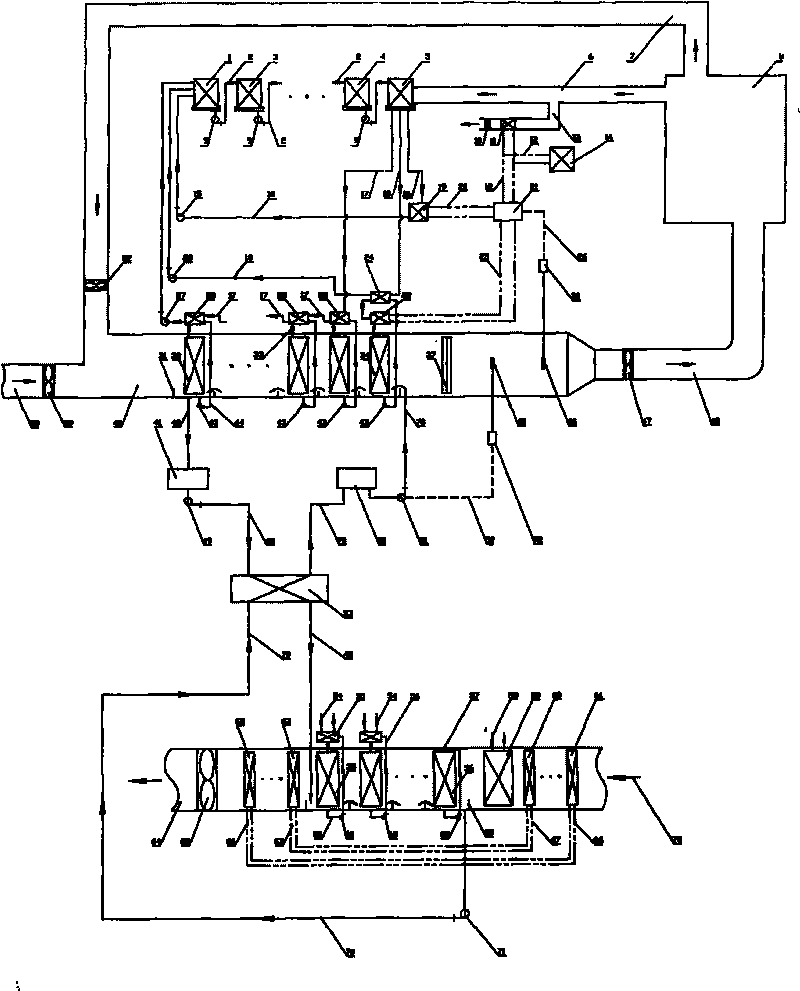

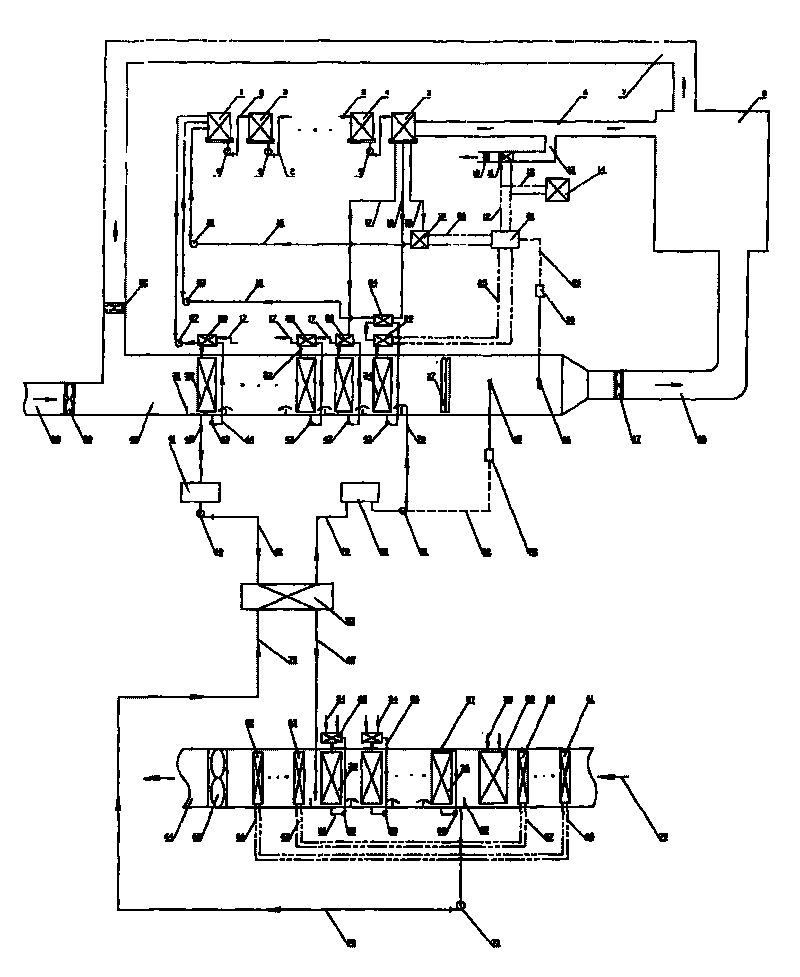

Embodiment 1

[0037] Fresh air duct 38, fresh air fan 39, return air duct 7, return air fan 22, air treatment section 40, liquid baffle 37, air supply fan 47, air supply duct 48, air user (air-conditioned room) of the present embodiment or drying room) 8, main exhaust air duct 6, branch exhaust air duct 13, and exhaust fan 10 constitute an air circulation subsystem, which makes the air circulate in the air duct and air treatment section through the power provided by various fans. and air users (air-conditioning room or drying room) between reasonable circulation, according to indoor and outdoor temperature and humidity changes, reasonable adjustment of fresh air, return air and exhaust air ratio, to achieve scientific air volume regulation; the working solution tank 31 of this embodiment, working solution Circulation pump 43, working solution supply pipe 44, working solution heat exchanger 28, 29, working solution liquid pipe 33, solution processing liquid device (internal structure is packe...

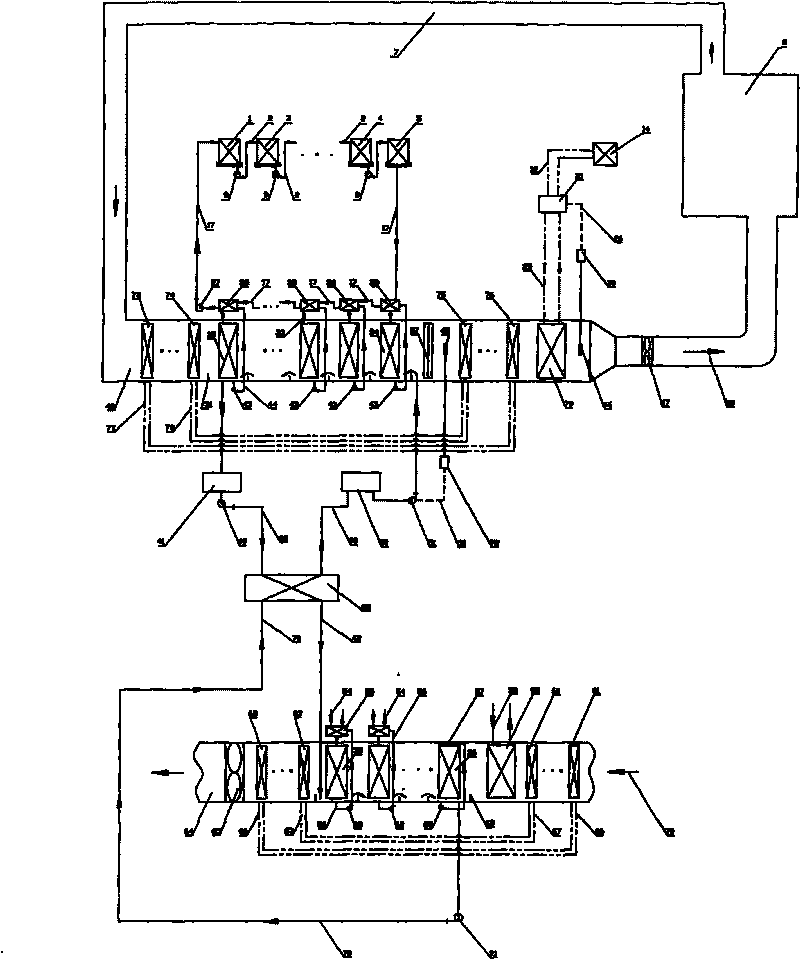

Embodiment 2

[0040] The return air duct 7 of the present embodiment, the air treatment section 40, the liquid baffle plate 37, the blower fan 47, the air supply duct 48, the air user (air-conditioning room or drying room) 8 etc. constitute the air circulation subsystem, and the subsystem The power provided by the blower fan makes the air circulate reasonably between the air duct, the air treatment section and the air user (air-conditioned room or drying room); the working solution tank 31 of this embodiment, the working solution circulating pump 43, the working solution Liquid supply pipe 44, working solution heat exchanger 28, working solution liquid distribution pipe 33, solution processing liquid separation device (internal structure can be packed bed type, can be packed tower type, can be spray chamber type, also can be spray Shower tube type; the packing in the packed tower type can be structured packing or bulk packing) 32, 34, etc. constitute an N-level solution processing subsystem ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com