Method for preparing Ag-SnO2-doped electrical contact material

A technology of electrical contact materials, silver tin oxide, applied in circuits, electrical switches, electrical components, etc., can solve problems such as contact resistance and excessive temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

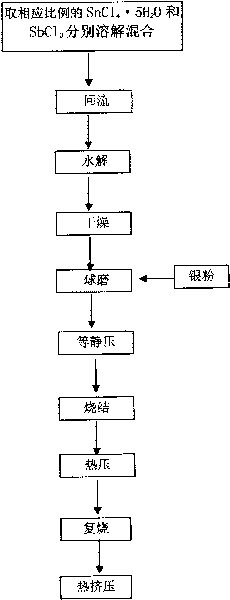

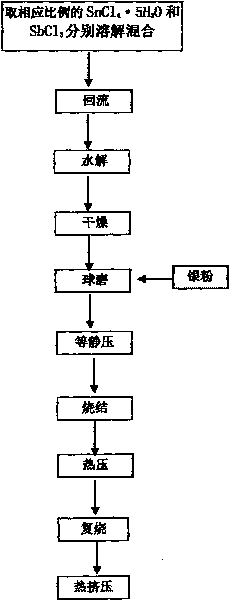

Method used

Image

Examples

Embodiment 1

[0030] 1. Take the corresponding SbCl at a mass ratio of 5:100 3 with SnCl 4 .5H 2 O, respectively dissolved in isopropanol and mixed.

[0031] 2. The mixed liquid was refluxed at 75°C and then centrifuged to remove the white precipitate to obtain the supernatant.

[0032] 3. Use ammonia water to drip into the clear liquid at 50°C, adjust the pH to between 2 and 3, and obtain milky yellow colloid.

[0033] 4. Dry the milky yellow colloid at 120°C for 4 hours and then dry at 600°C for 2 hours to obtain modified SnO 2 powder.

[0034] 5. Take modified SnO 2 powder and silver powder ball milling, wherein modified SnO 2 The powder accounted for 18% of the total weight, the ball-to-material ratio was 3:1, and the ball milling time was 20 hours.

[0035] 6. Then the ball-milled powder is pressed into a billet under an isostatic pressure of 300 MPa.

[0036] 7. Sinter the pressed green body at 900° C. for 4 hours in an air atmosphere.

[0037] 8. Hot press the sintered green...

Embodiment 2

[0042] 1. Take the corresponding SbCl at a mass ratio of 6:100 3 with SnCl 4 .5H 2 O, respectively dissolved in isopropanol and mixed.

[0043] 2. The mixed liquid was refluxed at 78°C and then centrifuged to remove the white precipitate to obtain the supernatant.

[0044] 3. Use ammonia water to drip into the clear liquid at 60°C, adjust the pH to between 2 and 3, and obtain milky yellow colloid.

[0045] 4. Dry the milky yellow colloid at 120°C for 4 hours and then dry at 600°C for 2 hours to obtain modified SnO 2 powder.

[0046] 5. Take modified SnO 2 powder and silver powder ball milling, in which modified SnO 2 The powder accounts for 4% of the total weight, the ball-to-material ratio is 10:1, and the ball milling time is 20 hours.

[0047] 6. Then the ball-milled powder is pressed into a billet under isostatic pressure of 100MPa.

[0048] 7. Sinter the pressed green body at 700°C for 8 hours in an air atmosphere.

[0049] 8. Hot press the sintered green body at...

Embodiment 3

[0054] 1. Take the corresponding SbCl at a mass ratio of 7:100 3 with SnCl 4 .5H 2 O, respectively dissolved in isopropanol and mixed.

[0055] 2. The mixed liquid was refluxed at 80°C and then centrifuged to remove the white precipitate to obtain the supernatant.

[0056] 3. Use ammonia water to drip into the clear liquid at 70°C, adjust the pH to between 2 and 3, and obtain milky yellow colloid.

[0057] 4. Dry the milky yellow colloid at 120°C for 4 hours and then dry at 600°C for 2 hours to obtain modified SnO 2 powder.

[0058] 5. Take modified SnO 2 powder and silver powder ball milling, in which modified SnO 2 The powder accounts for 10% of the total weight, the ball-to-material ratio is 5:1, and the ball milling time is 6 hours.

[0059] 6. Then the ball-milled powder is pressed into a billet under isostatic pressure of 250MPa.

[0060] 7. Sinter the pressed green body at 800° C. for 6 hours in an oxygen atmosphere.

[0061] 8. Hot press the sintered green bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com