Method for directly chemically synthesizing rare-earth vanadium-doped yttrium phosphate nanocrystalline material

A nanocrystalline material and rare earth doping technology, applied in chemical instruments and methods, nanotechnology, luminescent materials, etc., can solve the problems of easy agglomeration of rare earth doped vanadium yttrium phosphate nanocrystals, high energy consumption, environmental pollution, and uneven particle size and other issues to achieve unique competitive advantages, low cost, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

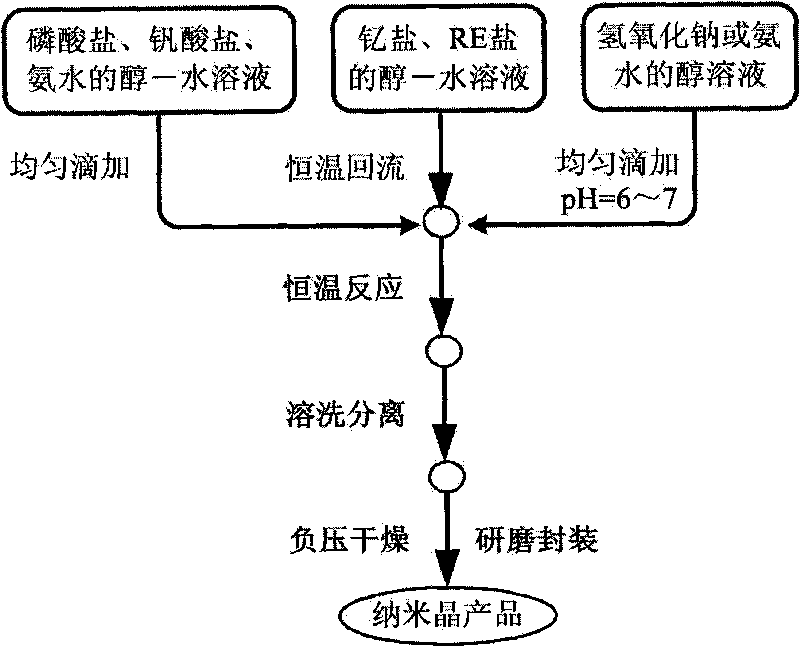

Method used

Image

Examples

Embodiment 1

[0042] 0.091mol yttrium nitrate is dissolved in 1000ml dehydrated alcohol and is placed in the reflux vessel; 0.009mol europium oxide (Eu 2 o 3 ) was dissolved in 3g concentrated nitric acid (63wt%) to obtain an aqueous solution of europium nitrate, then diluted with 200ml of deionized water to obtain a transparent solution, and moved into the above-mentioned reflux container to obtain a mixed solution A; 0.05mol ammonium metavanadate, 0.05mol hydrogen phosphate Dissolve diammonium and 0.10mol-0.20mol ammonia water into 300ml deionized water to obtain a mixed solution B; dissolve 0.05mol caustic soda into 100ml absolute ethanol to obtain a solution C; put the mixed solution A in the above-mentioned reflux container at a constant temperature around 76°C Reflux, add solution C dropwise, and adjust the pH value of mixed solution A to 5-7; then, start to drop mixed solution B evenly into mixed solution A, and add solution C appropriately during the period to control the pH value b...

Embodiment 2

[0044] Dissolve 0.08mol yttrium chloride and 0.02mol europium nitrate in a mixed solvent of 150ml ethanol and 1000ml deionized water to obtain a solution, and move it into a reflux container to obtain a mixed solution A; 0.05mol ammonium metavanadate, 0.05mol hydrogen phosphate Dissolve diammonium and 0.10mol-0.20mol ammonia water into 500ml deionized water to obtain mixed solution B; dissolve 0.05mol caustic soda into 100ml absolute ethanol to obtain solution C; put the mixed solution A in the above-mentioned reflux container at a constant temperature around 76°C Reflux, add solution C dropwise, and adjust the pH value of mixed solution A to 5-7; then, begin to drop mixed solution B evenly into mixed solution A, during which solution C is added dropwise to control the pH value between 5-7. After the dropwise addition is completed, continue the constant temperature reaction for 4h-6h to fully crystallize the nanocrystals; then alternately wash with ethanol, methanol, and deioni...

Embodiment 3

[0046] Dissolve 0.085mol of yttrium nitrate and 0.015mol of terbium chloride in 1000ml of absolute ethanol and place in a reflux container, then dilute with 1000ml of deionized water to obtain mixed solution A; mix 0.05mol of ammonium metavanadate, 0.05mol of sodium phosphate and 0.10mol of - Dissolve 0.20mol of ammonia water into 1000ml of deionized water to obtain mixed solution B; dissolve 0.025mol of caustic soda into 100ml of absolute ethanol to obtain solution C; reflux the above-mentioned mixed solution A in the reflux container near a constant temperature of 76°C, and add the solution dropwise C. Adjust the pH value of the mixed solution A to 5-7; then, start to evenly drop the mixed solution B into the mixed solution A, during which the solution C is properly added to control the pH value between 5-7. After the dropwise addition is completed, continue the constant temperature reaction for 4h-6h to fully crystallize the nanocrystals; then alternately wash with ethanol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com