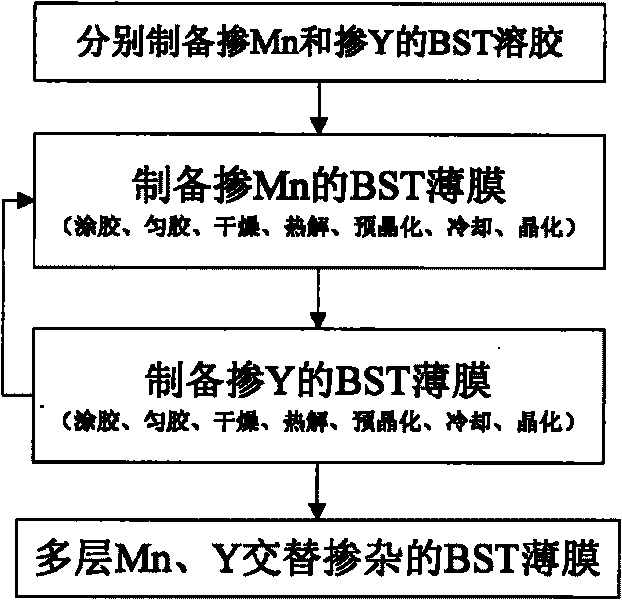

Method for preparing binary alternatively-doped BST membrane

A technology of alternate doping and thin film, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of large difference in composition between thin film and target material, expensive equipment, and slow deposition rate of radio frequency magnetron sputtering, etc., to achieve improvement Interface matching relationship, the effect of improving the comprehensive dielectric tuning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

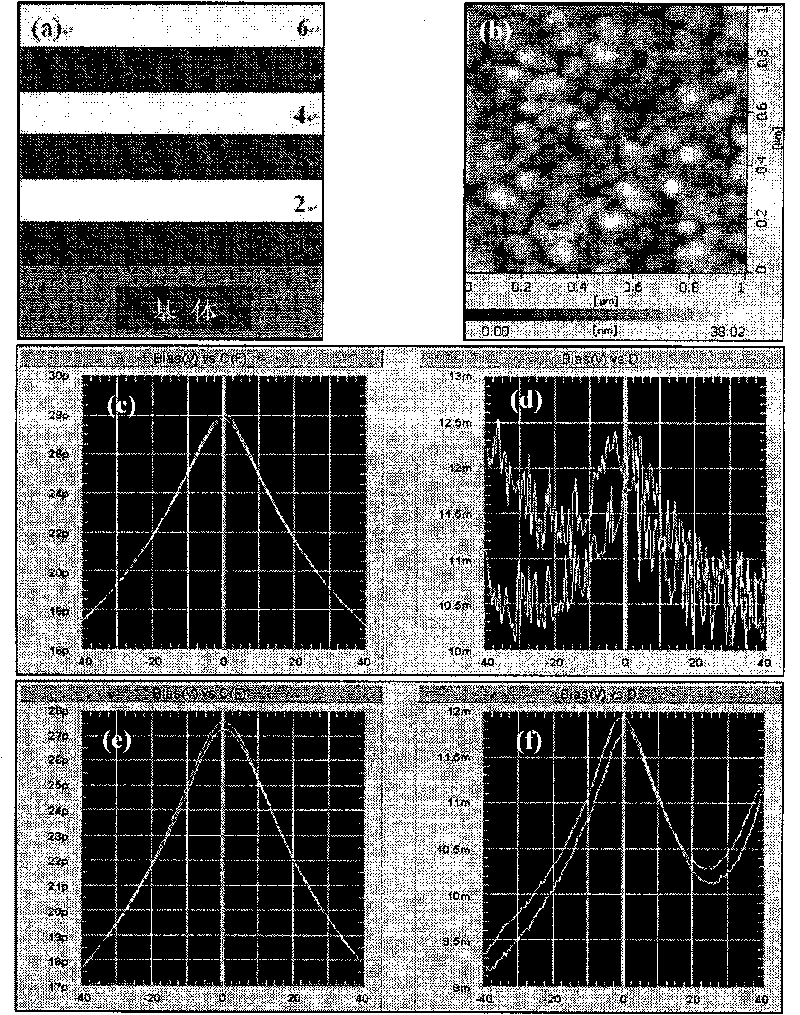

[0045] Embodiment 1 prepares Si / SiO 2 Six layers of 1mol% Mn and 1mol% Y alternately doped BST films on / Ti / Pt substrate.

[0046] According to technical scheme described in the present invention in Si / SiO 2 / Ti / Pt substrate prepared six layers of 1mol% Mn and 1mol% Y alternately doped BST thin films, such as figure 2 shown. Wherein, the doping concentration of Mn or Y refers to the percentage doping concentration relative to the molar weight of barium strontium in the BST sol (all the following examples are the same); Odd layers are doped with Mn and pre-crystallized, and even layers are doped with Y and pre-crystallized. crystallize.

[0047] The prepared BST thin film such as figure 2 , where: (a) is a schematic diagram of the film structure, (b) is the AFM morphology of the film, (c) and (d) correspond to the capacitance and dielectric loss of the film at 100kHz, respectively, (e) and (f) Corresponding to capacitance and dielectric loss at 1MHz, respectively.

[00...

Embodiment 2

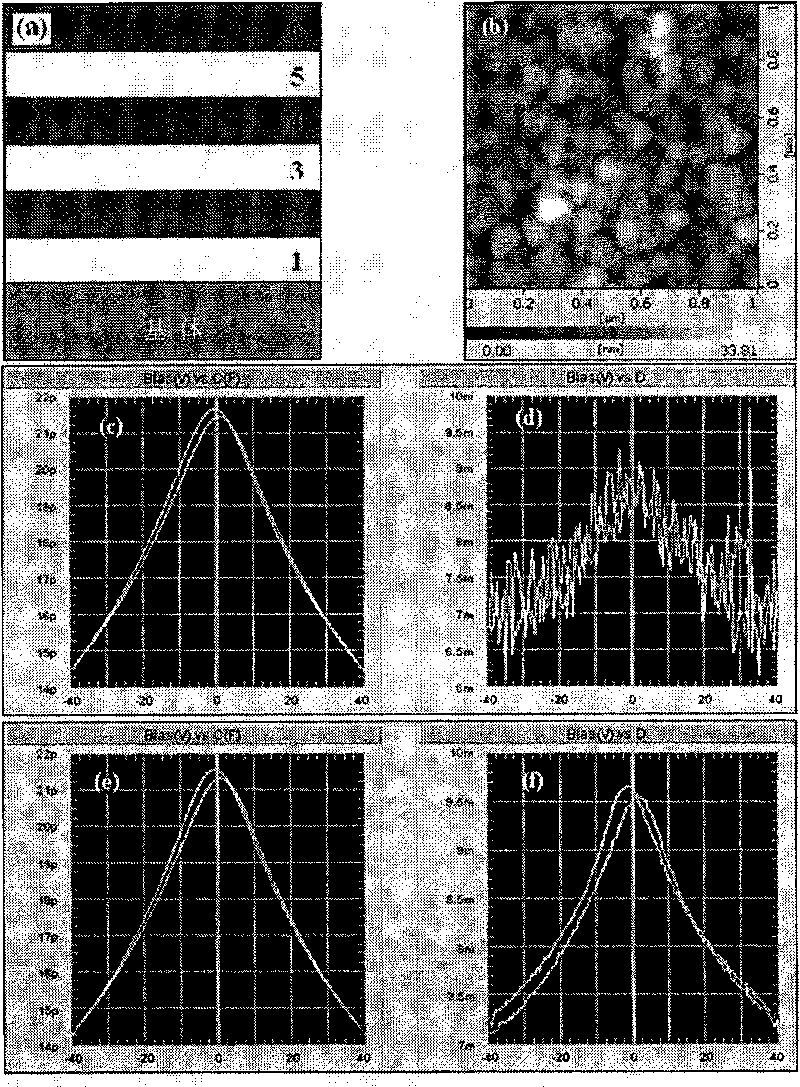

[0049] Embodiment 2 prepares Si / SiO 2 Six layers of 1mol% Y and 1mol% Mn alternately doped BST films on / Ti / Pt substrate.

[0050] According to technical scheme described in the present invention in Si / SiO 2 Six layers of 1mol% Y and 1mol% Mn alternately doped BST thin films prepared on / Ti / Pt substrate, such as image 3 shown. The odd-numbered layers are doped with Y and pre-crystallized, and the even-numbered layers are doped with Mn and pre-crystallized.

[0051] The prepared BST thin film such as image 3 , where: (a) is a schematic diagram of the film structure, (b) is the AFM morphology of the film, (c) and (d) correspond to the capacitance and dielectric loss of the film at 100kHz, respectively, (e) and (f) Corresponding to capacitance and dielectric loss at 1MHz, respectively.

[0052] Depend on image 3 It can be seen that the surface of the BST film is smooth, dense, and free of cracks, but the grain boundaries are clearer, and the average size of nanocrystal g...

Embodiment 3

[0053] Embodiment 3 prepares Si / SiO 2 Six layers of 1.5mol% Mn and 1.5mol% Y alternately doped BST films on / Ti / Pt substrate.

[0054] According to technical scheme described in the present invention in Si / SiO 2 Six layers of 1.5mol% Mn and 1.5mol% Y alternately doped BST thin films prepared on / Ti / Pt substrate, such as Figure 4 shown. The odd-numbered layers are doped with Mn and pre-crystallized, and the even-numbered layers are doped with Y and pre-crystallized.

[0055] The prepared BST thin film such as Figure 4 , where: (a) is a schematic diagram of the film structure, (b) is the AFM morphology of the film, (c) and (d) correspond to the capacitance and dielectric loss of the film at 100kHz, respectively, (e) and (f) Corresponding to capacitance and dielectric loss at 1MHz, respectively.

[0056] Depend on Figure 4 It can be seen that the surface of the BST thin film is smooth, dense and free of cracks, and the average grain size is about 50nm. At 100kHz: the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com