Graft copolymer of amino-containing starch and methyl acrylate

A technology of methyl acrylate and graft copolymer, applied in the field of graft copolymer, can solve problems such as heavy metal ions need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0013] The grafting rate and nitrogen content of the following examples are determined by the following method:

[0014] Determination of nitrogen content: use the Kjeldahl method to determine the nitrogen content in the sample, and then calculate it according to the following formula:

[0015] Nitrogen content%=[(V-V 0 )N / W]×0.014×100

[0016] Where: V-the number of milliliters of HCl consumed, mL;

[0017] V 0 -Milliliters of HCl consumed in the blank experiment;

[0018] N-HCl equivalent concentration

[0019] W- sample weight, g

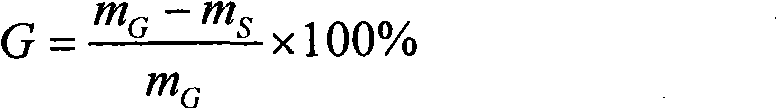

[0020] Method for measuring grafting rate: Gravimetric method is used to determine the grafting rate (G, %). Wrap the dried crude product with filter paper, place it in a 250ml Soxhlet extractor to extract the homopolymer, wash, filter and vacuum dry to constant weight to obtain a pure graft copolymer.

[0021] Calculated as follows:

[0022] G = m G - m S m G X 100 %

[0023] Where: m S ——Reaction starch quality, g;

[002...

example 1

[0026] Take 5g of tapioca starch and 50mL of distilled water into a 250mL three-necked flask, stir into starch milk and then pass nitrogen into it; add 0.15g of cerium ammonium nitrate and 15g of methyl acrylate, heat up to 30℃ and react for 9h, use NaCO 3 The solution is neutralized to neutrality to obtain starch grafted methyl acrylate copolymer. Take 2g of the obtained copolymer (dry basis), add 30mL of hydrazine hydrate, stir, condense and reflux at 85°C for 10h to obtain a white gel-like product, precipitate and wash the product with absolute ethanol, and dry under vacuum at 50°C to obtain hydrazine amine hydrate The modified starch is grafted with methyl acrylate copolymer. The graft ratio (G) of the copolymer was measured to be 73.2%, and the nitrogen content was 13.8%.

example 2

[0027] Example 2 Take 10g of potato starch and 50mL of distilled water into a 250mL three-necked flask, stir into starch milk and then pass in nitrogen; add 0.05g of ammonium persulfate and 6.5g of methyl acrylate, heat up to 30℃ for 2h reaction, use NaCO 3 The solution is neutralized to neutrality to obtain starch grafted methyl acrylate copolymer. Take 2g of the obtained copolymer (dry basis), add 15mL of hydrazine hydrate, stir, condense and reflux at 95°C for 6h to obtain a white gel-like product, precipitate and wash the product with absolute ethanol, and dry under vacuum at 50°C to obtain hydrazine amine hydrate The modified starch is grafted with methyl acrylate copolymer. The graft rate (G) of the copolymer was measured to be 29.12%, and the nitrogen content was 1.88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com