Soluble polyimide liquid crystal vertical alignment agent, prepration method and liquid crystal box prepared thereby

A soluble polyimide, vertical alignment technology, used in liquid crystal materials, chemical instruments and methods, nonlinear optics, etc., can solve the problems of narrow viewing angle, slow response time, low contrast, etc. , the effect of fast response time and simple molecular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

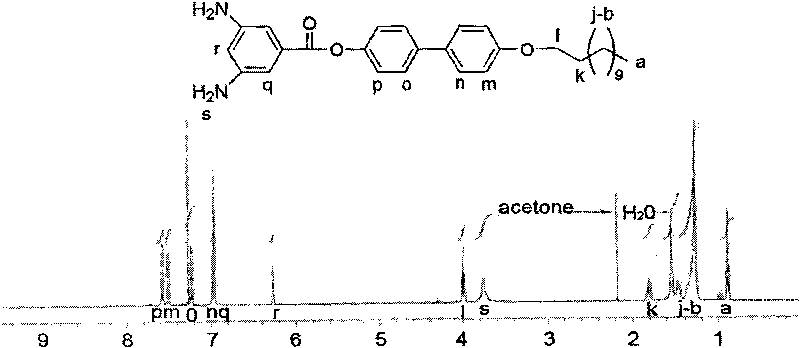

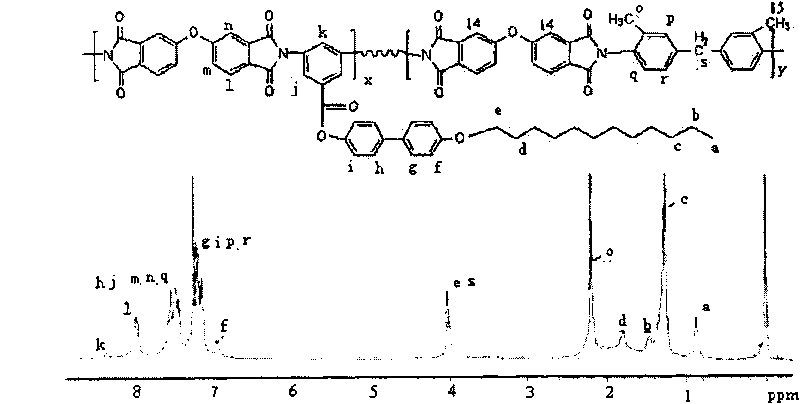

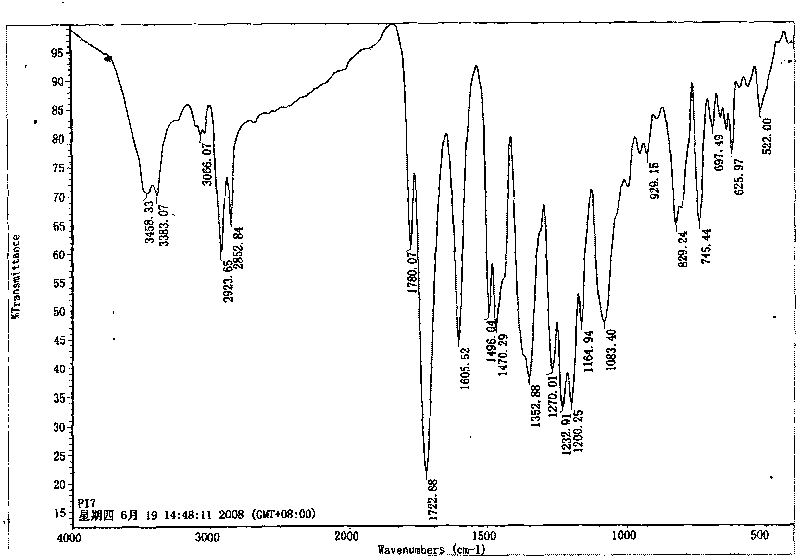

[0037] 1.1 Preparation of monomer specific structure diamine

[0038] a. Preparation of 4'-dodecyloxy-4-hydroxybiphenyl

[0039] Add 1 part of 4,4'-dihydroxybiphenyl and 1 part of potassium hydroxide into a three-necked flask with a stirrer, add 40 parts of methanol and stir at a temperature of about 70°C to dissolve completely, then add 1 part of bromo Add dodecane into the reactor, stir and react for about 24 hours, stop the reaction, cool to about 15°C and filter, pour the filtrate into distilled water about 4 times its volume for precipitation, and suction filter after sufficient precipitation, the obtained white solid is first Washing with dilute hydrochloric acid with a weight concentration of 8%, then repeatedly washing with distilled water for 3 times, drying for 24 hours, and recrystallizing with ethanol, the obtained product is the primary product for preparing diamine with a specific monomer structure;

[0040] b. Preparation of 4-dodecyloxybiphenol-3', 5'-dinitrob...

Embodiment 2

[0049] 2.1 Preparation of monomer specific structure diamine

[0050] a. Preparation of 4'-dodecyloxy-4-hydroxybenzene

[0051] Add 10 parts of 4,4'-dihydroxybenzene and 15 parts of potassium hydroxide into a three-necked flask with a stirrer, add 80 parts of methanol and stir at a temperature of about 50°C to dissolve completely, then add 10 parts of decabromide Add dioxane into the reactor, stir and react for about 36 hours, stop the reaction, cool to about 25°C and filter, pour the filtrate into distilled water about 5 times its volume for precipitation, and carry out suction filtration after sufficient precipitation, the obtained white solid is first used Washing with dilute hydrochloric acid with a weight concentration of 5%, then repeatedly washing with distilled water for 3 times, drying for 24 hours, and recrystallizing with ethanol, the obtained product is the primary product for preparing diamine with a specific monomer structure;

[0052] b. Preparation of 4-dodecy...

Embodiment 3

[0061] 3.1 Preparation of monomer specific structure diamine

[0062] a. Preparation of 4'-octyloxy-4-hydroxybiphenyl

[0063] Add 5 parts of 4,4'-dihydroxybiphenyl and 8 parts of potassium hydroxide into a three-necked flask with a stirrer, add 80 parts of methanol and stir at a temperature of about 60°C to dissolve completely, then add 5 parts of bromo Add n-octane into the reactor, stir and react for about 30 hours, stop the reaction, cool to about 20°C and filter, pour the filtrate into distilled water about 6 times its volume for precipitation, and suction filter after sufficient precipitation, the obtained white solid is first Washing with dilute hydrochloric acid with a weight concentration of 4%, then repeatedly washing with distilled water for 3 times, drying for 36 hours, and recrystallizing with ethanol, the obtained product is the primary product for preparing diamine with a specific monomer structure;

[0064] b. Preparation of 4-octyloxybiphenol-3', 5'-dinitrobe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com