Method for preparing shell-core micrometer/nanometer spheres capable of preventing functional materials

A technology of functional substances and nanospheres is applied in the field of preparation of core-shell micro/nanospheres, which can solve the problems of easily damaged active substance activity, difficult biomacromolecule coupling, limited biomedical applications, etc. The preparation method is simple and easy to operate, and the operability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

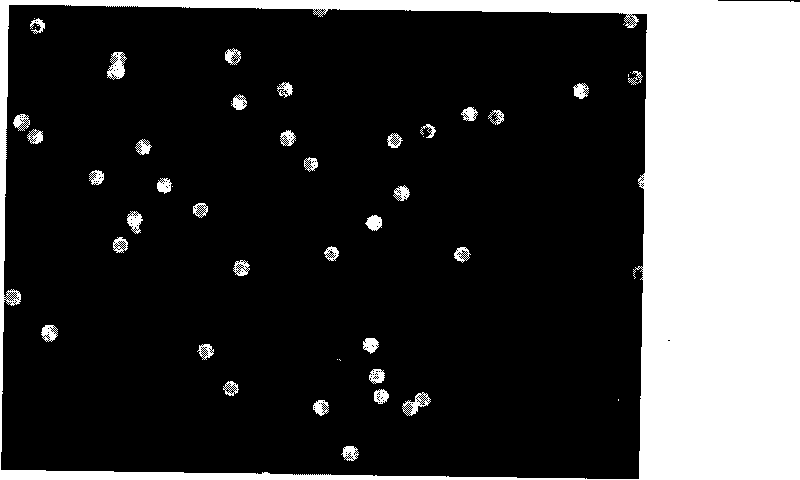

[0033](1) Prepare a mixed solution of deionized water and isopropanol with a volume ratio of 1:5, and add 100 mg of fluorescent polystyrene microspheres (12 μm) loaded with CdSe / ZnS quantum dots to the above 100 mL mixed solution; (2 ) Weigh 10mg of polyvinylpyrrolidone (PVP) into the above system, stir to dissolve and disperse for 60min; (3) Add 1mL tetraethyl orthosilicate (TEOS) to the above system at room temperature, and stir for 30min; (4) Add 1mL Ammonia water was added to the above system, and the reaction was closed with stirring for 24 hours. The obtained product is centrifuged at high speed, washed with water, and the obtained product can be maintained for a long time in PBS buffer solution. It can be seen from the figure that the quantum dot fluorescent microspheres with the core-shell structure have good dispersion and high fluorescence intensity (calculated, after the core-shell structure wraps, the fluorescence efficiency of the quantum dot fluorescent microsphe...

Embodiment 2

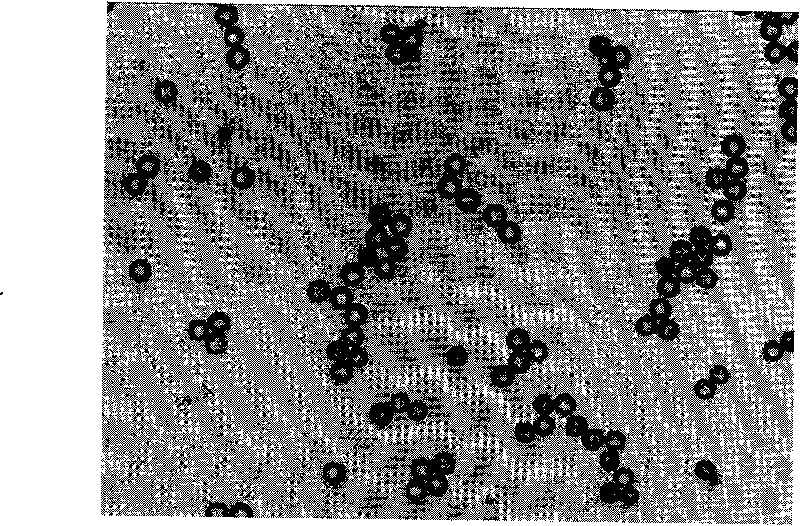

[0035] (1) Prepare a mixed solution of deionized water and isopropanol with a volume ratio of 1:3, and 10 mg of Fe 3 o 4 Magnetic polystyrene microspheres (12μm) were added to the above 10mL mixed solution; (2) 1mg of polyvinylpyrrolidone (PVP) was weighed and added to the above system, and stirred to dissolve and disperse for 10min; (3) At room temperature, 0.01mL of normal Ethyl silicate (TEOS) was added to the above system, and stirred for 30 minutes; (4) 0.01 mL of ammonia water was added to the above system, and stirred for 24 hours to seal the reaction. The obtained product is centrifuged at high speed, washed with water, and the obtained product can be kept in deionized water for a long time. It can be seen from the figure that the ferroferric oxide magnetic microspheres with a core-shell structure have good dispersion, and a single sphere is black, and black ferric oxide nanoparticles are successfully wrapped in the microspheres.

Embodiment 3

[0037] (1) Prepare a mixed solution of deionized water and isopropanol with a volume ratio of 1:7, add 50 mg of Cy5-loaded fluorescent polyacrylamide microspheres (3 μm) to the above 50 mL mixed solution; (2) weigh 6 mg Add polyvinylpyrrolidone (PVP) to the above system, stir to dissolve and disperse for 30 minutes; (3) add 0.5mL tetraethyl orthosilicate (TEOS) to the above system at room temperature, and stir for 30 minutes; (4) Add 0.5mL ammonia water to To the above-mentioned system, stir and close the reaction for 24h. The obtained product is centrifuged at high speed, washed with water, and the obtained product can be kept in ethanol for a long time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com