Adsorbent for polyaromatic hydrocarbon pollutant, preparation method and application thereof

A technology for polycyclic aromatic hydrocarbons and pollutants, which is applied to water pollutants, chemical instruments and methods, and adsorption water/sewage treatment. It can solve the problems of high cost and difficult regeneration of adsorption materials, and achieve good water effluent effect and lipophilicity. The effect of increasing and increasing the number of lipophilic groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

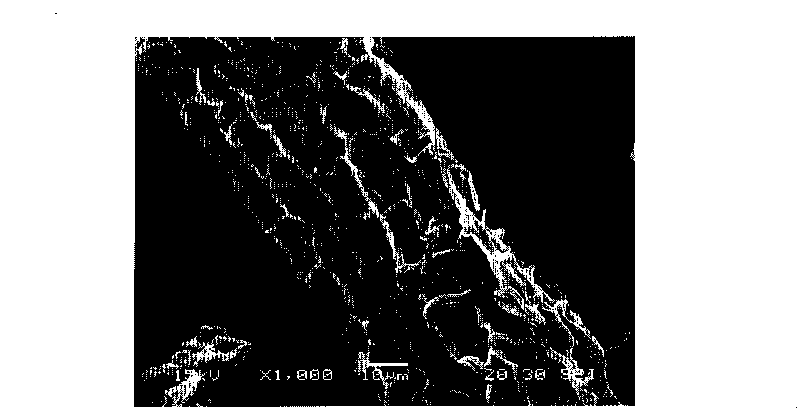

[0031] Crush the natural peat through a 100-200 mesh sieve, weigh 10g of natural peat and add it to 1250ml NaOH solution with pH=12, stir at 500r / m for 20min, filter with suction, and wash with deionized water repeatedly until the pH of the cleaning water is ≈7. Dry at 80° C. for 10 h to obtain peat after alkali washing (alkali washing peat B). Take by weighing 5g of alkali-washed peat again, modify according to the ratio of peat: CTAB: water=1: 1: 250 (mass ratio), shake in a water bath at 55°C for 6h, and rotate at 150r / m. Wash with deionized water until no foam is generated, take it out and dry it at 80°C for 10 hours, grind and sieve to obtain alkali-washed modified peat (modified peat C). The modified peat prepared by the above steps is analyzed by SEM scanning electron microscope, and the photos obtained are shown in the attached description. figure 1 .

Embodiment 2

[0033]Crush the natural peat through a 100-200 mesh sieve, weigh 10g of natural peat and add it to 1250ml of NaOH solution with pH=12, stir at 500r / m for 20min, filter with suction, and wash with deionized water repeatedly until the pH of the cleaning water is ≈7 , and dried at 80°C for 10 hours to obtain peat after alkali washing. Then weigh 5g of alkali-washed peat, modify it according to the ratio of peat: CTAB: water=1: 1: 250 (mass ratio), oscillate in a water bath at 40°C for 6 hours, and rotate at 150r / m. After the reaction is completed, the solution is suction filtered and used Wash with deionized water until no foam is generated, take it out and dry it at 80°C for 10 hours, grind and sieve to obtain alkali-washed modified peat. The alkali-washed peat and modified peat worth the above steps are subjected to a static adsorption test at room temperature (25°C) to 50ml, 1mg / L phenanthrene solution. After 12h, the maximum adsorption capacity of natural peat is 0.75mg / g. T...

Embodiment 3

[0035] Dry and crush the natural rice straw through a 100-mesh sieve, weigh 20g of natural rice straw powder and add it to 1250ml of NaOH solution with pH = 12, stir at 500r / m for 30min, filter with suction, and wash with deionized water repeatedly until the pH of the washing water ≈ 7. Dry at 80°C for 10 hours to obtain alkali-washed straw. Then take 10g of alkali-washed rice straw, modify it according to the ratio of rice straw: tetrabutylammonium bromide (TBAB): water=1: 0.5: 250 (mass ratio), shake in a water bath at 80°C for 6h, and rotate at 150r / m. After the completion, filter the solution with suction, wash it with deionized water until no foam is generated, take it out and dry it at 80°C for 10 hours, grind it and sieve it to obtain the alkali-washed TBAB modified straw. The alkali-washed rice straw and modified rice straw worth the above steps are carried out static adsorption test at room temperature (25°C) to 100ml, 1mg / L phenanthrene solution. After 12h, the adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com