Method for separating and purifying immunoglobulin A, immunoglobulin G and lactoferrin from bovine colostrum in industrializing way

A technology for separation and purification of immunoglobulins, which is applied in the field of industrial separation and purification of immunoglobulin A, immunoglobulin G and lactoferrin, can solve the problems of inability to carry out industrial amplification, purification of immunoglobulins, and restrictions on industrial production, and achieve High production efficiency, pollution reduction, high biological activity and high purity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

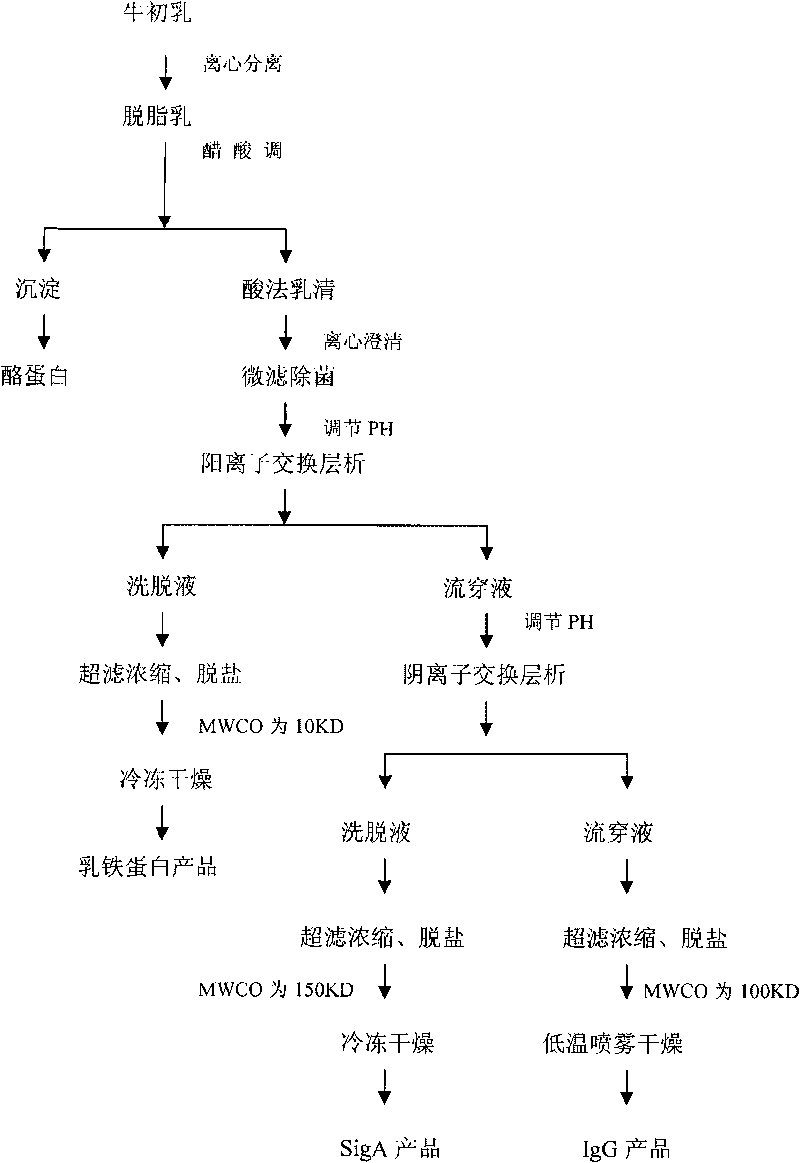

[0024] Example 1 Industrial separation and purification of immunoglobulin A, immunoglobulin G and lactoferrin from bovine colostrum

[0025] (1) Preparation of whey

[0026] Selection of bovine colostrum raw materials: select the milk produced within 48 hours after giving birth;

[0027] Degreasing: continuous disc centrifuge degreasing, temperature 45°C, speed 5500rpm;

[0028] Whey preparation: Use acetic acid to adjust the pH of skim milk to 4.6, keep it warm at 40°C for 20 minutes, use a horizontal centrifuge to separate casein, and then go through a continuous disc clarifier centrifuge to remove casein particles. The whey pH was adjusted to 6.0.

[0029] (2) Prepare lactoferrin

[0030] Microfiltration sterilization: use French TAMI ceramic membrane with a pore size of 0.45um for microfiltration sterilization, operating pressure 0.1-0.2Mpa, operating temperature 20-35°C, tangential flow rate 4-6m / s, sterilization rate 100%;

[0031] Cation exchange chromatography: sel...

Embodiment 2

[0037] The identification of the lactoferrin product that embodiment 2 method of the present invention obtains

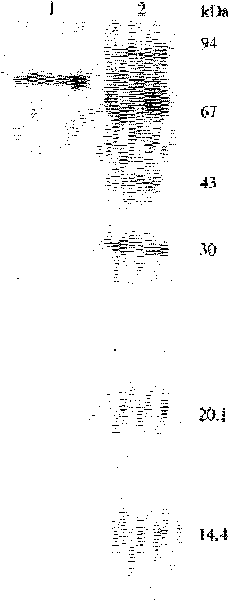

[0038] Determination of Sodium Dodecyl Sulfate Polyacrylamide Electrophoresis (SDS-PAGE)

[0039]The lactoferrin product that embodiment 1 is obtained is measured through sodium dodecyl sulfate polyacrylamide electrophoresis (SDS-PAGE), and the lactoferrin of gained is a single band, as figure 2 As shown, the single strip on column 1 is the lactoferrin band with a relative molecular weight of 80000Da.

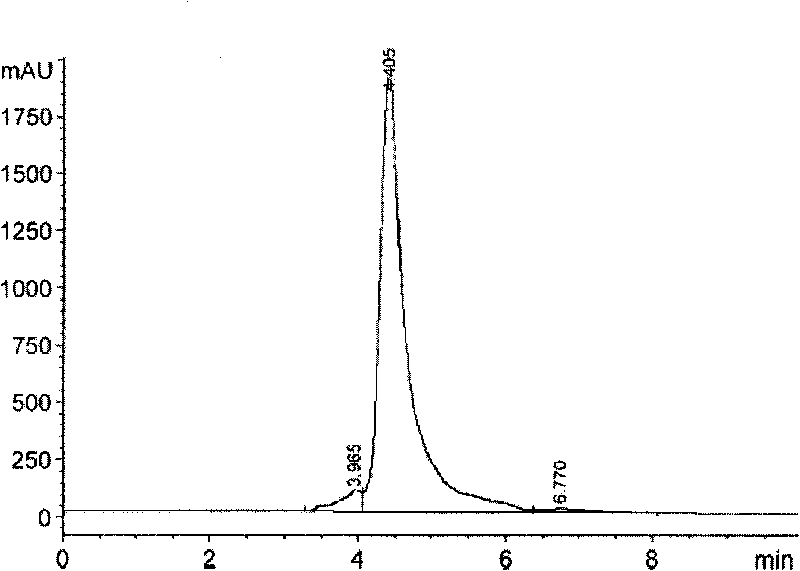

[0040] HPLC (High Performance Liquid Chromatography) Determination

[0041] HPLC conditions of use: TSK-G3000PWxl gel chromatography column is selected, mobile phase: 0.02mol / L, pH 6.8 phosphate buffer, the prepared mobile phase needs to use pure water, and the mobile phase is filtered through a 0.22μm microporous filter before use. Membrane suction filtration to prevent insoluble particles in the salt from damaging the equipment, and ultrasonic degassing for 20 m...

Embodiment 3

[0046] The identification of the immunoglobulin A product that embodiment 3 method of the present invention obtains

[0047] Determination of Sodium Dodecyl Sulfate Polyacrylamide Electrophoresis (SDS-PAGE)

[0048] The immunoglobulin A (SigA) product obtained in Example 1 was determined by sodium dodecyl sulfate polyacrylamide electrophoresis (SDS-PAGE), and the obtained SigA band was clear, and the relative molecular weight was 390000Da.

[0049] Western blot detection

[0050] Western blot detection method: cut 2 pieces of 3MM ultra-thick filter paper and a piece of nitrocellulose membrane (NC membrane), the size of which is about gel > filter paper ≥ NC membrane. The NC membrane was equilibrated with deionized water for 30 minutes, and the cut 3MM ultra-thick filter paper and NC membrane were soaked in the transfer buffer for 5 minutes. After SDS-PAGE is over, remove the gel and pre-equilibrate in deionized water for 5 minutes. On the semi-dry electroporation instrument,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com