Anti-impact epoxy structural rubber and preparation method thereof

An epoxy structural adhesive and impact-resistant technology, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of poor aging resistance, low impact resistance and compression strength, poor toughness, etc., and achieve thermal stability The effects of non-reduced resistance, good compatibility, and improved impact strength and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

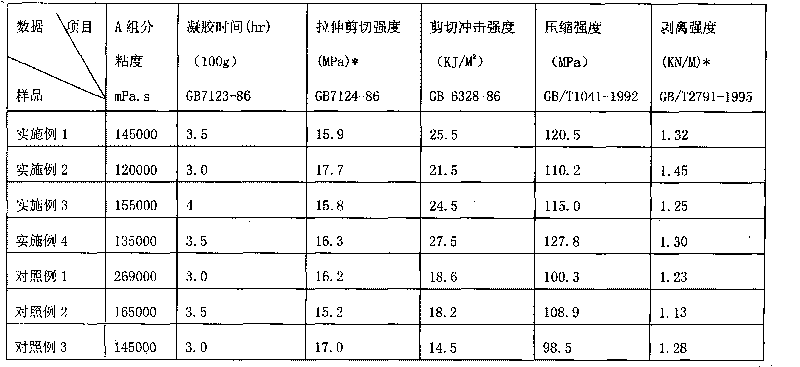

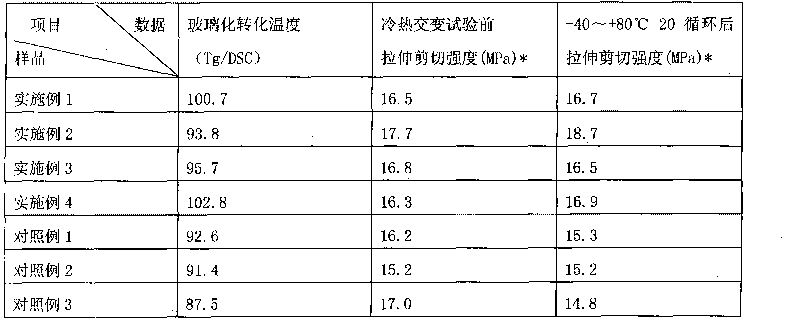

Examples

Embodiment 1

[0042]Embodiment 1: Taking nanometer rubber particle modified bisphenol A epoxy resin E-51 as example:

[0043] Pretreatment of nano-rubber particles: Weigh 200g of epoxy resin active diluent 1.6 hexanediol diglycidyl ether, 275g of E-51 bisphenol A epoxy resin in a 2000ML glass beaker, add 25g of BYK-P104S wetting and dispersing agent , stirred with a stirrer for 10 minutes; Weighed 500g of superfine fully vulcanized carboxylated nitrile rubber powder and slowly added it to the beaker while stirring, stirred for 1 hour, and left standstill for 24 hours to obtain pretreated nano-rubber particles for subsequent use (total amount 1Kg) ;

[0044] Nano-rubber particle modified E-51: Weigh 389g of E-51 epoxy resin, place it in a 1.5L double planetary power mixing kettle with a high-speed emulsifier, heat the resin to 90°C, and weigh the above-mentioned pretreated nano-rubber particles Add 150g of 150g to the mixing kettle in small amounts while stirring at a speed of 600 rpm; turn...

Embodiment 2

[0050] Embodiment 2: Taking nanometer rubber particle modified bisphenol A epoxy resin E-51 as example:

[0051] Pretreatment of nano-rubber particles: Weigh 200g of epoxy active diluent butyl glycidyl ether BGE, 283.3g of E-51 bisphenol A epoxy resin, put them in a 2000ML glass beaker; add 16.7g of BYK-161 wetting and dispersing agent , stirred with a mixer for 10 minutes; Weighed 500 g of superfine fully vulcanized carboxylated nitrile rubber powder and slowly added it to the beaker while stirring, stirred for 1 hour, and left to stand for 24 hours to obtain pretreated nano-rubber particles for subsequent use;

[0052] Nano-rubber particle modified E-51: Weigh 466g of E-51 epoxy resin, place it in a 1.5L dual planetary power mixing kettle with a high-speed emulsifier, heat the resin to 90°C, and weigh the above-mentioned pretreated nano-rubber particles 120g was added to the mixing tank several times while stirring at a speed of 600 rpm; the high-speed emulsifier was turned ...

Embodiment 3

[0058] Embodiment 3, taking nanometer rubber particle modified bisphenol F epoxy resin BFE170 as example:

[0059] Pretreatment of nano-rubber particles: Weigh 200g of epoxy resin active diluent 1.6 hexanediol diglycidyl ether, 275g of bisphenol F epoxy resin BFE170 in a 2000ML glass beaker, add 25g of BYK-P104S wetting and dispersing agent, and use Mixer stirred for 10 minutes; Weighed 500g of nano-rubber particle powder, slowly added to the beaker while stirring, stirred for 1 hour, and left standstill for 24 hours to obtain pretreated nano-rubber particle, which was set aside (total amount 1Kg);

[0060] Bisphenol F epoxy resin BFE170 modified by nano-rubber particles: Weigh 295g of BFE170 epoxy resin, place it in a 1.5L double planetary power mixing kettle with a high-speed emulsifier, heat the resin to 90°C, and weigh the above-mentioned pretreated nano Add 200g of rubber particles to the mixing kettle in small amounts and multiple times while stirring at a speed of 600 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com