Method for simultaneously preparing hydrogen and zinc oxide powder

A technology of zinc oxide powder and hydrogen, which is applied in the field of energy chemistry and can solve problems such as the inability to obtain hydrogen and zinc oxide powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

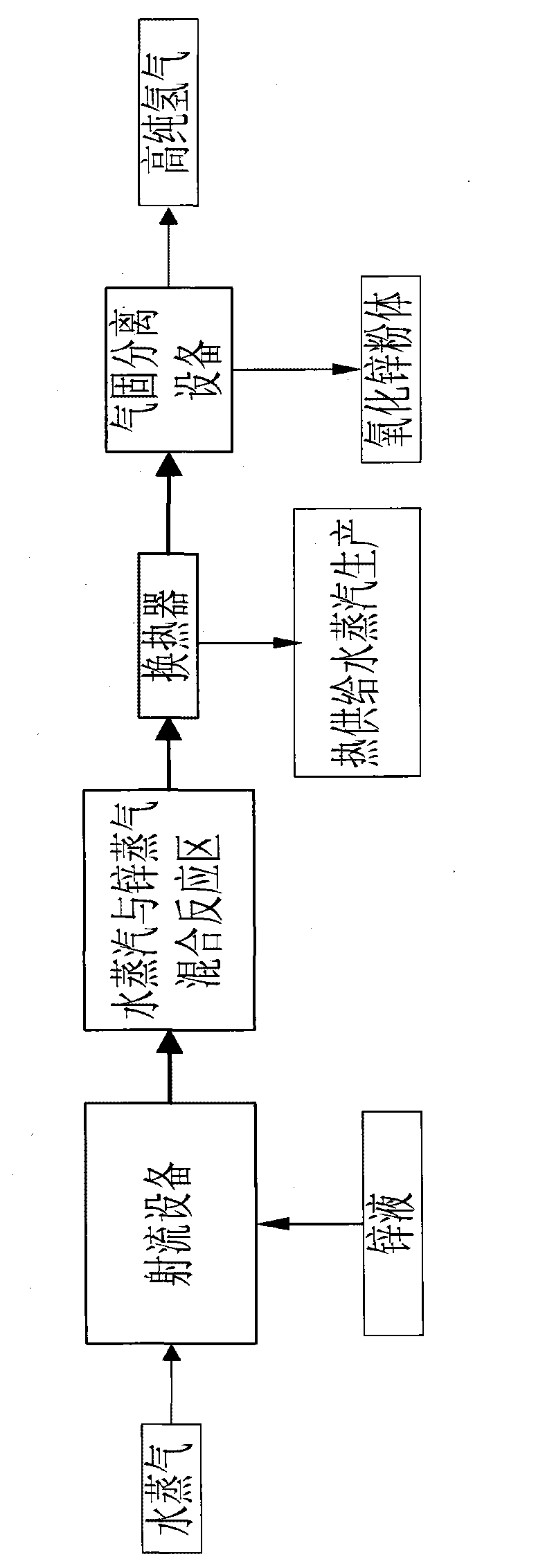

Image

Examples

Embodiment 1

[0025] Water vapor flow: 0.2g / min

[0026] Water vapor inlet temperature: 673K

[0027] Zinc liquid temperature: 1000K

[0028] Vacuum pressure of liquid zinc container: 0.01MPa (saturated evaporation temperature 989K)

[0029] The temperature of the mixed reaction zone of water vapor and zinc vapor is 900K

[0030] Metal zinc chemical conversion rate: 93%

[0031] Zinc oxide powder particle size: 0.10μm~2.0μm

[0032] Zinc oxide crystal form: hexagonal crystal structure

[0033] Hydrogen yield: 125Ncm 3 / min

Embodiment 2

[0035] Water vapor flow: 2.4g / min

[0036] Water vapor inlet temperature: 673K

[0037] Zinc liquid temperature: 1120K

[0038] Vacuum pressure of liquid zinc container: 0.05MPa (saturated evaporation temperature 1114K)

[0039] The temperature of the mixed reaction zone of water vapor and zinc vapor is 1020K

[0040] Metal zinc chemical conversion rate: 90%

[0041] Zinc oxide powder particle size: 0.05μm~1.5μm

[0042] Zinc oxide crystal form: hexagonal crystal structure

[0043] Hydrogen yield: 1.8×10 4 Ncm 3 / min

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com