Beta''-Al2O3 solid electrolyte precursor aqueous tape casting slurry and preparation method thereof

A solid electrolyte, water-based casting technology, which is applied in the field of β″-Al2O3 solid electrolyte precursor water-based casting slurry and its preparation, can solve the problems of undiscovered solid electrolyte film, etc. The effect of good capacitance and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

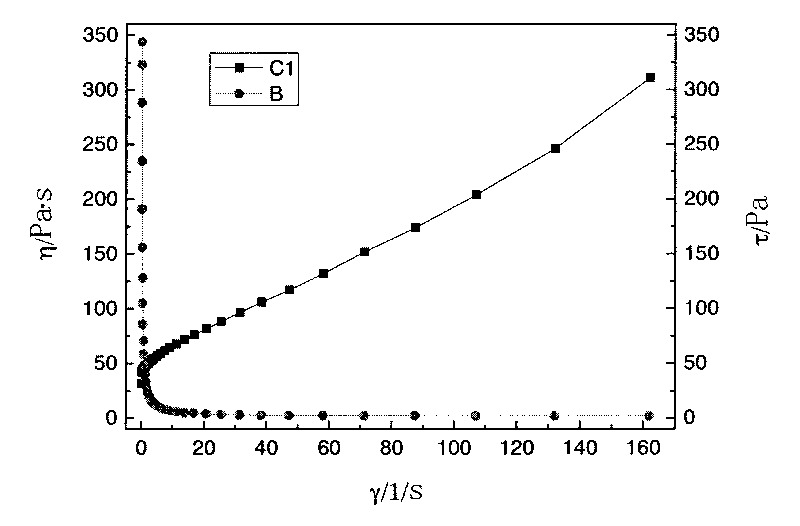

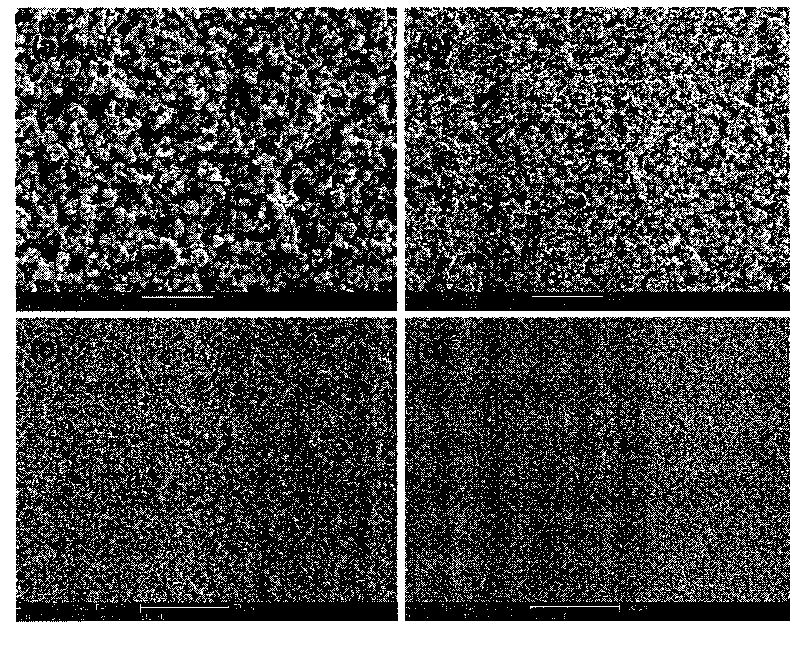

Embodiment 1

[0021] The ammonium citrate dispersant that accounts for 0.05wt% of the total amount is uniformly dispersed in 54.95wt% deionized water, and 15wt% (corresponding volume percentage content is 36%) of β"-Al 2 o 3 The precursor powder was ball milled for 18 hours, and the powder was evenly dispersed in deionized water to form slurry A; in A, the mixture of polyvinyl alcohol (PVA) and polyvinylpyrrolidone (PVB) was added (wherein PVA Accounting for 25% of the total weight percentage of PVA and PVB) as a binding agent, then add 5wt% propylene glycol as a plasticizer, continue ball milling for 20 hours, or stir for 8 hours to obtain slurry B; slurry B is filtered, vacuum Degassing to get β″-Al 2 o 3 Water-based casting slurry for solid electrolyte precursor. The slurry is cast on a polyethylene terephthalate (PET) casting film tape coated with silicone oil, and after the casting film is dried at 25° C. for 6 hours, the casting film is separated from the PET film tape, namely The...

Embodiment 2

[0023] The polyammonium methacrylate dispersant that accounts for 0.5wt% of the total amount is uniformly dispersed in 56.5wt% deionized water, and 20wt% (corresponding volume percentage content is 44%) of β"-Al 2 o 3 The precursor powder was ball milled for 15 hours, and the powder was uniformly dispersed in deionized water to form slurry A; in A, the mixture of polyvinyl alcohol (PVA) and polyvinylpyrrolidone (PVB) was added (wherein PVA account for 20% of the total weight percentage of PVA and PVB) as a binding agent, then add 3wt% glycerol as a plasticizer, continue ball milling for 12 hours, or stir for 8 hours to obtain slurry B; slurry B is filtered, vacuum Degassing to get β″-Al 2 o 3 Water-based casting slurry for solid electrolyte precursor. The slurry is cast on a polyethylene terephthalate (PET) cast film tape coated with silicone oil, and after the cast film is dried at 35° C. for 4 hours, the cast film is separated from the PET film tape, and then It can obta...

Embodiment 3

[0025] The Duramax D3005 ammonium polyacrylate dispersant, which accounts for 0.8wt% of the total amount, is uniformly dispersed in 53.2wt% deionized water, and 27wt% (corresponding to a volume percentage of 54%) of β″-Al is added 2 o 3 The precursor powder was ball milled for 12 hours, and the powder was evenly dispersed in deionized water to form slurry A; 18wt% of WB4101 polyacrylic acid was added to A as a binding agent, and then 1wt% of polyethylene glycol (PEG ) as a plasticizer, continue ball milling for 8 hours, or stir for 8 hours to obtain slurry B; filter slurry B and vacuum degas to obtain β″-Al 2 o 3 Water-based casting slurry for solid electrolyte precursor. The slurry is cast on a polyethylene terephthalate (PET) cast film tape coated with silicone oil, and after the cast film is dried at 45° C. for 2 hours, the cast film is separated from the PET film tape, and then It can obtain β″-Al with flat and smooth surface, uniform particle distribution, good flexibi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com