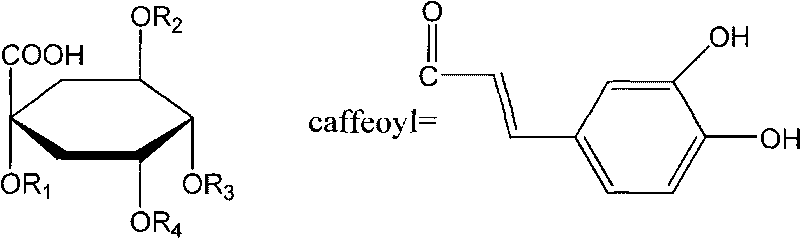

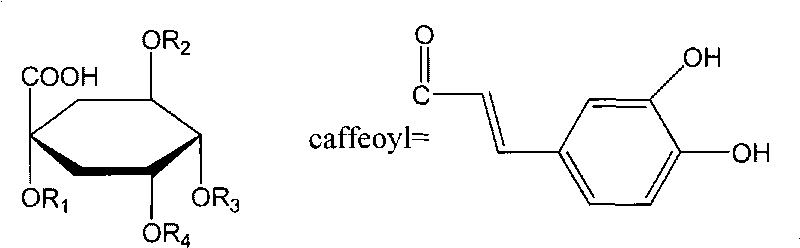

Separation purifying method for DCQA (dicaffeoylquinic acid) component in jerusalem artichoke

A caffeoylquinic acid and purification method technology, which is applied in the separation/purification of carboxylic acid esters, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of strong toxicity and side effects, and no extraction and purification methods. Achieve the effects of easy enrichment, rich content and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

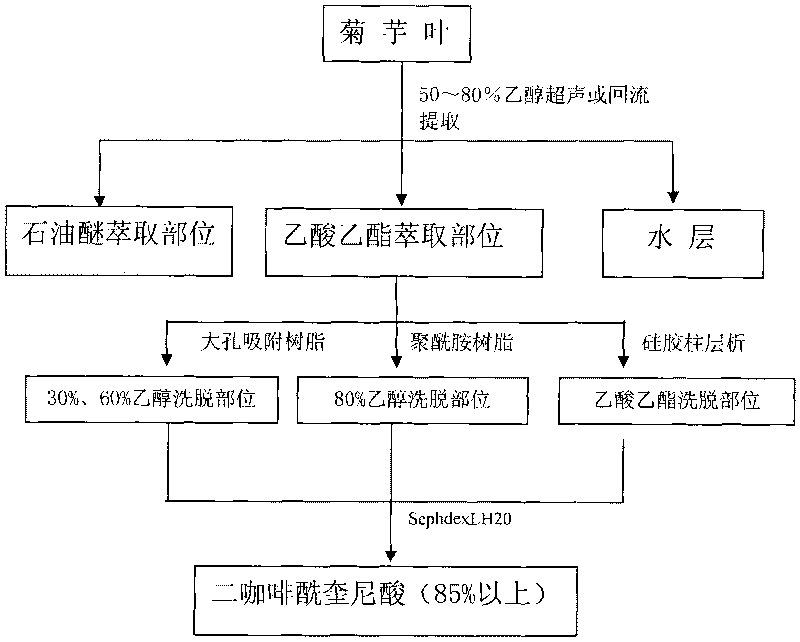

Method used

Image

Examples

Embodiment 1

[0027] Dry and crush Jerusalem artichoke leaves, weigh 40g, soak in 600ml of ethanol with a volume concentration of 70% for 12 hours, ultrasonicate for 45 minutes, filter, and save the filtrate for later use; add 520ml of ethanol with a volume concentration of 70% to soak for about 6 hours, and ultrasonically for 45 minutes , filtered; the filtrates were combined, and the filter residue was discarded. The filtrate was concentrated under reduced pressure to remove ethanol to obtain a crude extract, which was extracted with petroleum ether of the same volume as the crude extract for a total of 4 extractions. After removing the fat-soluble components, it was extracted with ethyl acetate of the same volume as the crude extract for a total of Extracted 4 times, the ethyl acetate extract was concentrated under reduced pressure to obtain an extract, which was dissolved in ethanol with a volume concentration of 20%, and then packed into a polyamide (30-60 mesh) column for chromatograph...

Embodiment 2

[0029]Dry and crush Jerusalem artichoke leaves, weigh 40g, soak in 600ml of ethanol with a volume concentration of 70% for 12 hours, ultrasonicate for 45 minutes, filter, and save the filtrate for later use; add 520ml of ethanol with a volume concentration of 70% to soak for about 6 hours, and ultrasonically for 45 minutes , filtered; the combined filtrates were discarded. The filtrate was concentrated under reduced pressure to remove ethanol to obtain a crude extract, which was extracted with petroleum ether of the same volume as the crude extract for a total of 4 extractions. After removing the fat-soluble components, it was extracted with ethyl acetate of the same volume as the crude extract for a total of Extracted 4 times, concentrated the ethyl acetate extract under reduced pressure to obtain the extract, dissolved the extract in ethanol with a volume concentration of 20%, and packed it into a column with D101 macroporous adsorption resin for separation. , 60% ethanol el...

Embodiment 3

[0031] Dry and crush Jerusalem artichoke, weigh 40g, soak in 600ml of ethanol with a volume concentration of 70% for 12 hours, ultrasonicate for 45 minutes, filter, and save the filtrate for later use; add 520ml of ethanol with a volume concentration of 70% to soak for about 6 hours, and ultrasonically for 45 minutes , filtered; the combined filtrates were discarded. The filtrate was concentrated under reduced pressure to remove ethanol to obtain a crude extract, which was extracted with petroleum ether of the same volume as the crude extract for a total of 4 extractions. After removing the fat-soluble components, it was extracted with ethyl acetate of the same volume as the crude extract for a total of Extracted 4 times, the ethyl acetate extract was concentrated under reduced pressure to obtain an extract, and after the extract was dissolved in ethanol, silica gel with the same quality as the extract was added and concentrated under reduced pressure to dryness to obtain a sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com