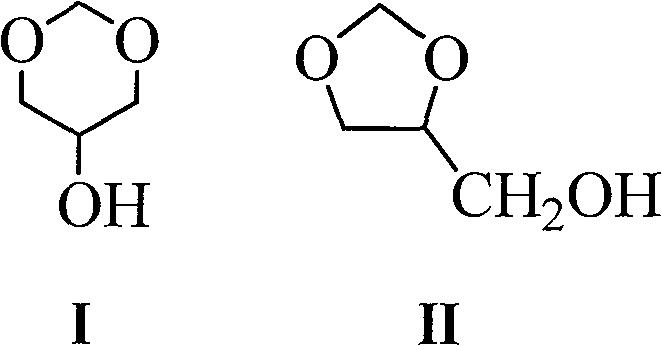

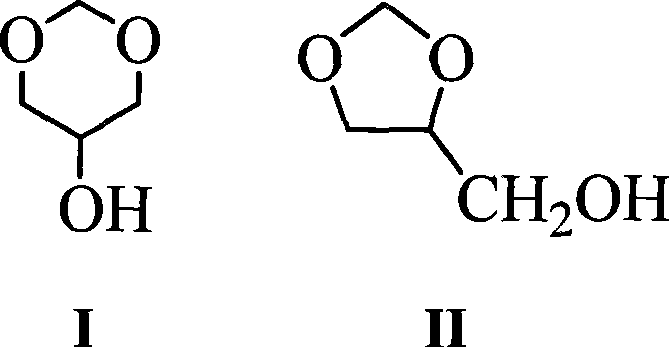

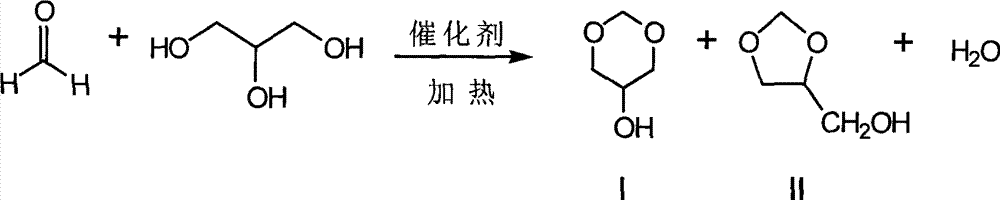

Method for synthesizing glycerol formal through reaction of glycerol and formaldehyde

A technology of glycerin formal and glycerin, which is applied in the direction of organic chemistry, can solve the problems of low selectivity of target products, poisonous and harmful catalysts, and non-recyclability, etc., and achieve good industrial application prospects, environmental friendliness, and pollution reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add glycerin 18.4g (0.2mol), 37% formaldehyde aqueous solution 19.4g (0.24mol), N-methyl-N'-butanesulfonic acid in the 100ml round-bottomed flask with water trap and reflux condenser Functionalized ionic liquid of imidazole trifluoromethanesulfonate 1×10 -3 mol, cyclohexane with water, reflux at 100°C for 4 hours. After the reaction was finished, the internal standard was added to the reaction solution, and the yield of the product was 85.2% according to GC quantitative analysis, and the ratio of I and II in the product was 72:28.

Embodiment 2

[0029] Add glycerin 18.4g (0.2mol), 37% formaldehyde aqueous solution 19.4g (0.24mol), N-methyl-N'-butanesulfonic acid in the 100ml round-bottomed flask with water trap and reflux condenser Functionalized ionic liquid of imidazole trifluoromethanesulfonate 4×10 -4 mol, cyclohexane with water, reflux at 100°C for 4 hours. After the reaction was finished, the internal standard was added to the reaction solution, and the yield of the product was 75.2% according to GC quantitative analysis, and the ratio of I and II in the product was 76:24.

Embodiment 3

[0031] Add glycerol 18.4g (0.2mol), 37% formaldehyde aqueous solution 19.4g (0.24mol), N-methyl-N'-butanesulfonic acid in the 100ml round-bottomed flask with water trap and reflux condenser Functionalized ionic liquid of imidazole trifluoromethanesulfonate 4×10 -3 mol, cyclohexane with water, reflux at 100°C for 4 hours. After the reaction was finished, the internal standard was added to the reaction solution, and the yield of the product was 81.9% according to GC quantitative analysis, and the ratio of I and II in the product was 59:41.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com