Method for removing phospholipids from paprika oleoresin

A technology for dephospholipting and capsicum, which is applied in the field of capsicum red dephospholipting, can solve the problems of affecting the dephosphorization process, exceeding the phospholipid content, and high phospholipid content, and achieving the effects of simple process and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the method for removing phospholipid in capsanthin in the production process

[0022] According to the different origins and varieties of capsanthin, the content of phospholipids in it varies greatly. So two options were tested. Option 1: Take 2.5L of mixed oil from the workshop, pour it into a separatory funnel and shake it evenly according to the weight ratio of mixed oil to acid aqueous solution of 1:0.5 (400g mixed oil, 200g 3‰ citric acid solution), and let it stand for stratification. Discard the acid solution in the lower layer, pour the mixed oil in the upper layer into a beaker, and place it in a 70-degree rotary evaporator to completely evaporate the solvent, then measure the color value and acetone insoluble matter of the remaining substances (AOCS method). Option 2, take 2.5L of mixed oil from the workshop, pour it into a separatory funnel according to the weight ratio of mixed oil to deionized water 1:0.5 (400g mixed oil, 200g deionized water...

Embodiment 2

[0024] Embodiment 2: the method for removing acetone insolubles in capsanthin in the production process

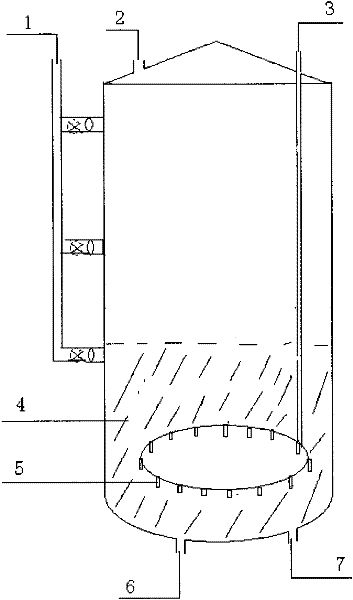

[0025] According to the test data, the 2007 production period will be officially applied. The raw materials are Jinta pepper and Yidu pepper from North China and Northeast China. Peppers are deseeded and stalked, crushed to 40-60 mesh, granulated, and sent to a 50-ton countercurrent rotary extractor on a conveyor belt. After continuous extraction, the saturated mixed oil solution is passed through a box filter and a double filter by a solvent pump. The device enters the pickling tank from bottom to top.

[0026] In advance, the treated softened water should be pumped into the acid water mixing tank in the workshop, and the weight of softened water is 2 tons per time. Open the inlet hole of the mixing tank and add 6kg of edible citric acid, stir to make the acid fully dissolve in water and enter the pickling tank from the acid water inlet. The acid water level is at the ...

Embodiment 3

[0027] Embodiment 3: the method for removing acetone insolubles in capsanthin in the production process

[0028] The operation step of embodiment two is identical, and raw material place of origin, kind are also identical, and 2008 annual production period changes citric acid aqueous solution into phosphoric acid aqueous solution. Finally, the acetone insoluble matter in all batches of the capsanthin product obtained is all between 0.5-1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com