Long-effective corrosion-prevention physical resistance-reducing agent

A long-term anti-corrosion and resistance-reducing agent technology, applied in conductive materials, conductors, conductive materials, etc., can solve the problem that bentonite cannot be used well, and achieve superior resistance-reducing performance, good anti-corrosion effect, and resistivity characteristics. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

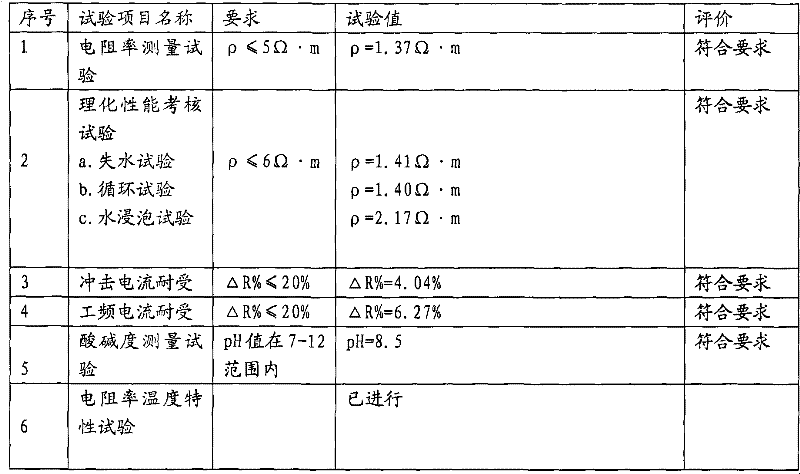

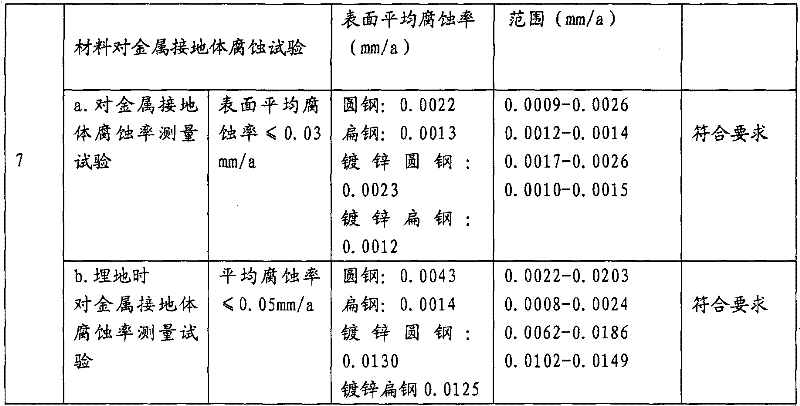

[0025] Example: take 15 kilograms of water-absorbing resin gel, 25 kilograms of conductive material graphite, 15 kilograms of activated carbon, 20 kilograms of sodium bentonite, and 25 kilograms of conductive cement at normal temperature and pressure to carry out physical mixing, after stirring evenly, bagging, and ready to serve. finished product.

[0026] The activated carbon used in this example is a columnar purified activated carbon with a strength of 100%, an iodine value (mg / g)=1100, a drying loss of 8%, a pH value of 8, and a phenol adsorption capacity (mg / g)=430, Ash content = 4%, packing density (g / mg) is 0.55.

[0027] The using method of the long-acting anti-corrosion physical drag-reducing agent of the present embodiment is:

[0028] Add the long-acting anti-corrosion physical drag-reducing agent (add water at the weight ratio of water:drag-reducing agent=0.4:0.6:1.0 and stir well until it becomes a sticky paste), and gently pour the prepared paste-like drag-redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com