Ordered short-channel magnetic mesoporous material

A technology of mesoporous materials and short channels, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., to achieve the effect of orderly and uniform channels, prevention of exposure and erosion, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

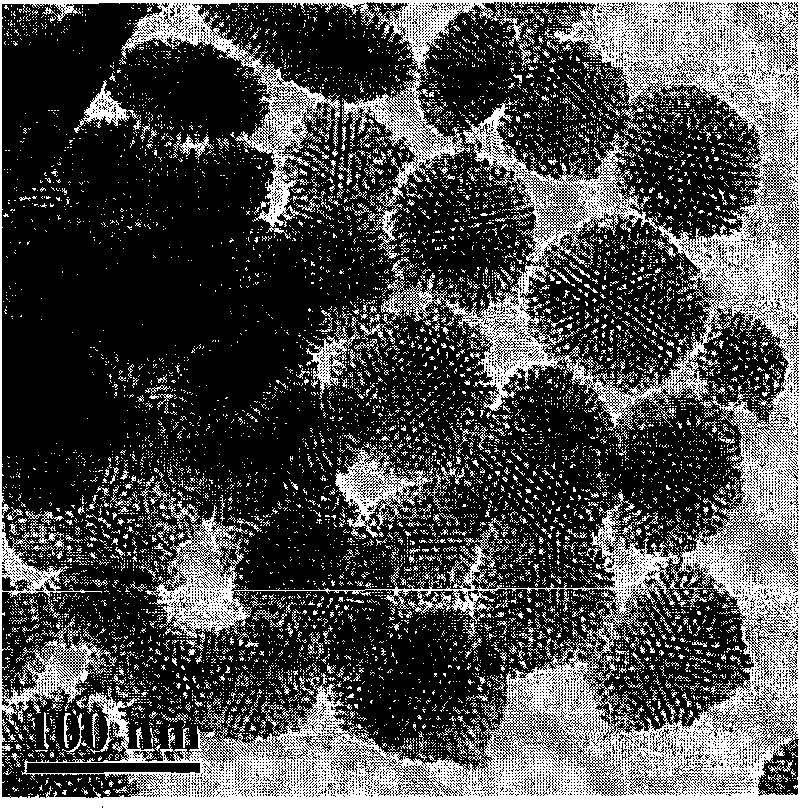

[0027] (1) Ferroferric oxide magnetic beads are prepared by hydrothermal method. Dissolve 7.4g of a mixture of ferrous chloride and ferric chloride with a molar ratio of 1:2 in 2M hydrochloric acid. After passing through nitrogen, add 30ml of ammonia water in a water bath at 40°C under mechanical stirring. The average diameter of the triferromagnetic nanoparticles is (6-16nm).

[0028](2) Under the action of ultrasound, the iron ferric oxide nano-magnetic beads are dispersed in 60ml of absolute ethanol solution, and under stirring in a water bath at 35°C, ethyl tetrasilicate is added, and the mass ratio of ethyl tetrasilicate to the magnetic beads is 5. After reacting for 3 hours, use a magnet to hold the magnetic beads; pour off the supernatant, wash the magnetic beads with absolute ethanol for 2-3 times, then add 50ml of absolute ethanol, and reflux in a water bath at 50°C for 8 hours; The magnet attracts the magnetic beads, pours off the supernatant, and obtains nano-magne...

Embodiment 2

[0034] (1) Ferroferric oxide magnetic beads are prepared by hydrothermal method. Dissolve 10.5 g of a mixture of ferrous chloride and ferric chloride with a molar ratio of 1:2 in 2M hydrochloric acid. After passing through nitrogen, add 60 ml of ammonia water in a water bath at 40°C under mechanical stirring. The average diameter of the triferromagnetic nanoparticles is (6-16nm).

[0035] (2) Under the action of ultrasound, the iron ferric oxide nano-magnetic beads are dispersed in 70ml of absolute ethanol solution, and under stirring in a water bath at 50°C, ethyl tetrasilicate is added, and the mass ratio of ethyl tetrasilicate to the magnetic beads is 2. After reacting for 5 hours, use a magnet to absorb the magnetic beads; pour off the supernatant, wash the magnetic beads with absolute ethanol for 3 times, then add 60ml of absolute ethanol, and reflux in a 70°C water bath for 10 hours; absorb with a magnet Hold the magnetic beads, pour off the supernatant, and get nano-ma...

Embodiment 3

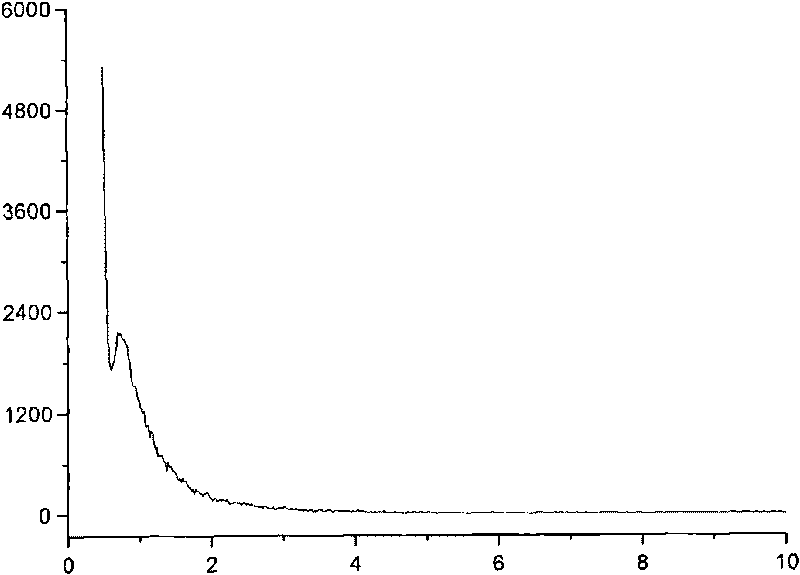

[0040] The obtained magnetic mesoporous material is used as the carrier of isobuprofen medicine.

[0041] Add 5mg of magnetic mesoporous material to a series of concentrations of isobuprofen in 3ml of n-hexane solution, the prepared concentration is as follows: 0.25mg / ml, 0.50mg / ml, 1.00mg / ml, 2.50mg / ml, 5.00mg / ml, 10.00mg / ml, 15mg / ml. Shake at a speed of 200rm for 12 hours, the carrier with the drug adsorbed is sucked by a magnet, and the concentration of the isobuprofen drug in the supernatant is calculated by the external standard method under the ultraviolet absorption of 264nm, and the isobuprofen in the supernatant is subtracted Drug content, and then calculate the adsorption amount of the isobuprofen drug of the magnetic mesoporous material. The resulting adsorption capacity curves are shown in Figure 4 , the maximum adsorption capacity of 5mg magnetic mesoporous material reached 1096.70mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com