Cu-Mn-based catalytic combustion catalyst for treatment of 'triphen' waste gas and preparation method thereof

A catalyst, copper-manganese technology, applied in physical/chemical process catalysts, combustion methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of less "triphenyl" exhaust gas and less catalyst research, and achieve Improve the activity, improve the low temperature catalytic activity, improve the effect of dispersion and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

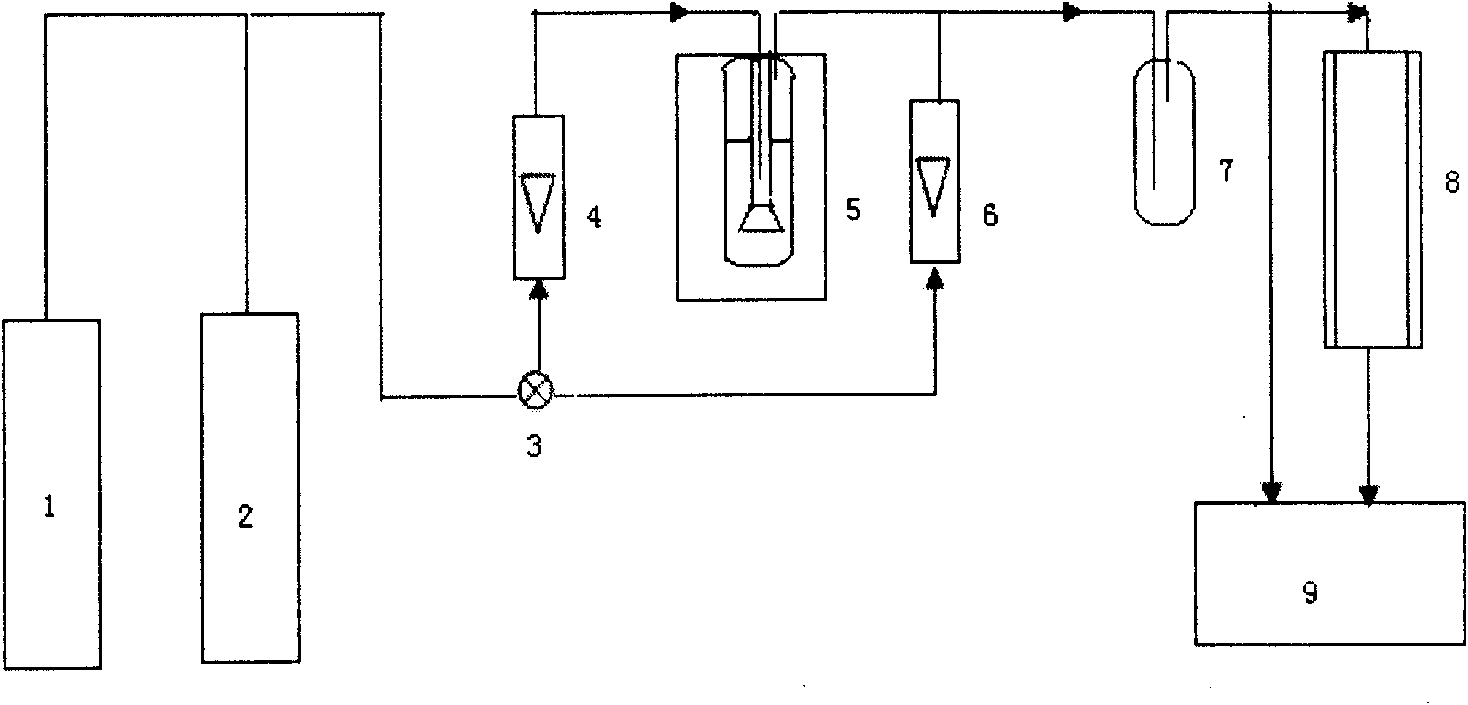

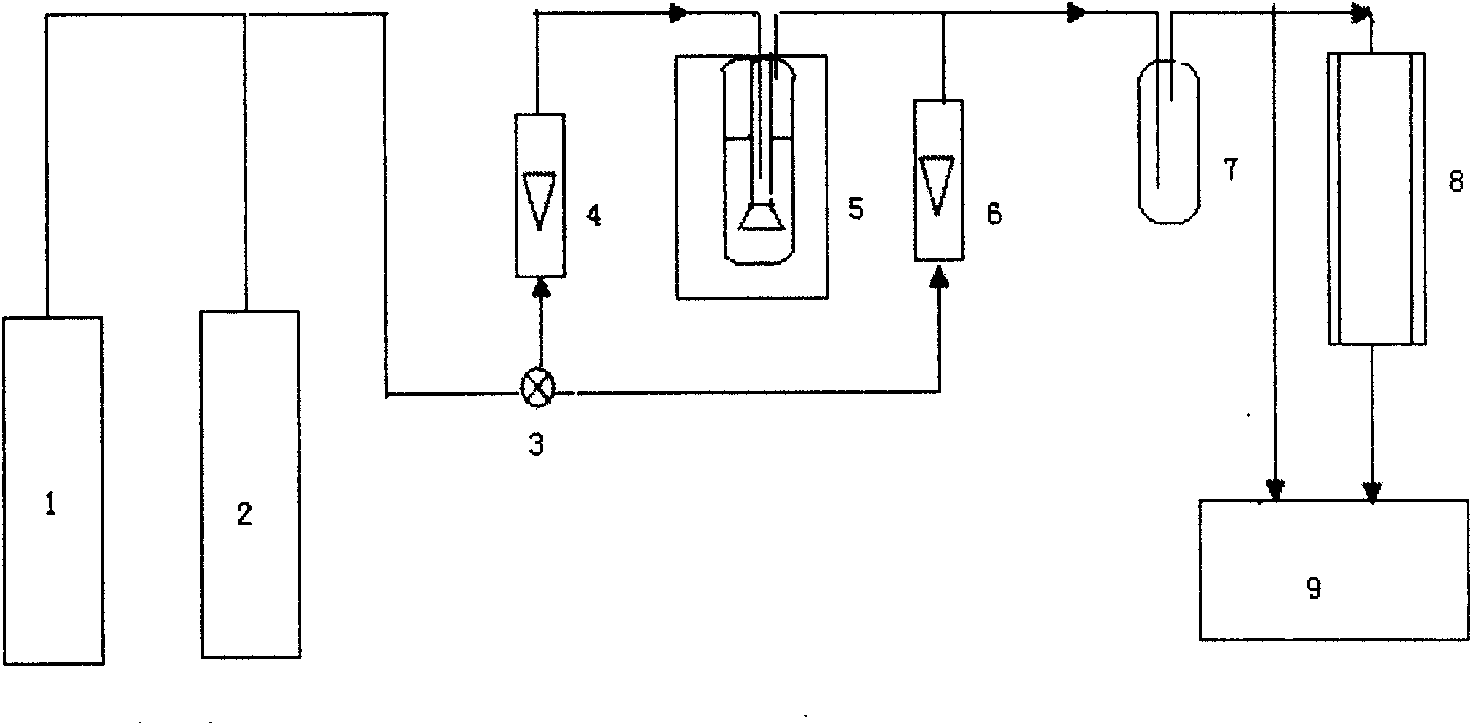

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Preparation of 8% CuMn 2 o 4 / 6%CeO 2 / Al 2 o 3

[0016] (a) 6% CeO 2 / Al 2 o 3 Preparation of composite carrier

[0017] According to the impregnating solution concentration C of cerium nitrate is 0.2147g / ml, take 8.6g of cerium nitrate and add 40ml of deionized water to fully dissolve to obtain a salt solution, immerse the dry spherical alumina, soak it at room temperature for 2 hours, and place it in a water bath at 50°C After soaking for 3 hours, take it out, dry it in an oven at 100°C for 5 hours, and then bake it in a muffle furnace at 550°C for 5 hours to obtain a 6% CeO 2 composite carrier. Catalyst activity test results: at a reaction temperature of 200-550°C, the conversion rate of benzene reaches 20%-70%, the conversion rate of toluene reaches 20%-70%, and the conversion rate of xylene reaches 20%-70%.

[0018] (b) 8% CuMn 2 o 4 / 6%CeO 2 / Al 2 o 3 Catalyst preparation

[0019] According to the concentration C of the impregnation ...

Embodiment 2

[0020] Embodiment 2: Preparation of 15% CuMn 2 o 4 / 6%CeO 2 / Al 2 o 3

[0021] The impregnating solution concentration C by copper-manganese composite oxide is 0.0014mol / ml, gets 10g copper nitrate, gets 20ml manganese nitrate solution and adds 10ml deionized water and fully dissolves and obtains salt solution, the composite carrier prepared in embodiment 1 (a) step Immerse in salt solution, immerse in room temperature for 2h, take out after immersing in 50°C water bath for 3h, dry in 100°C oven for 5h, and then bake in 550°C muffle furnace for 5h to obtain 15% CuMn 2 o 4 / 6%CeO 2 / Al 2 o3 catalyst. Activity evaluation of the catalyst: at a reaction temperature of 200-550°C, the conversion rate of benzene reaches 40%-90%, the conversion rate of toluene reaches 50%-100%, and the conversion rate of xylene reaches 50%-100%.

Embodiment 3

[0022] Embodiment 3: Preparation of 8% CuMn 2 o 4 / 11%CeO 2 / Al 2 o 3

[0023] (a) 11% CeO 2 / Al 2 o 3 Preparation of composite carrier

[0024] According to the concentration C of the cerium nitrate impregnating solution being 0.4533g / ml, take 27g of cerium nitrate and add 60ml of deionized water to fully dissolve to obtain a salt solution, immerse the dry spherical alumina, immerse at room temperature for 2h, then immerse in a water bath at 50°C for 3h and take it out. Dry in an oven at 100°C for 5h, and then bake in a muffle furnace at 550°C for 5h to obtain 2 composite carrier. Activity evaluation of the catalyst: at a reaction temperature of 200-550°C, the conversion rate of benzene reaches 20%-80%, the conversion rate of toluene reaches 20%-80%, and the conversion rate of xylene reaches 20%-80%.

[0025] (b) 8% CuMn 2 o 4 / 11%CeO 2 / Al 2 o 3 Catalyst preparation

[0026] According to the concentration C of the impregnation solution of copper-manganese com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com