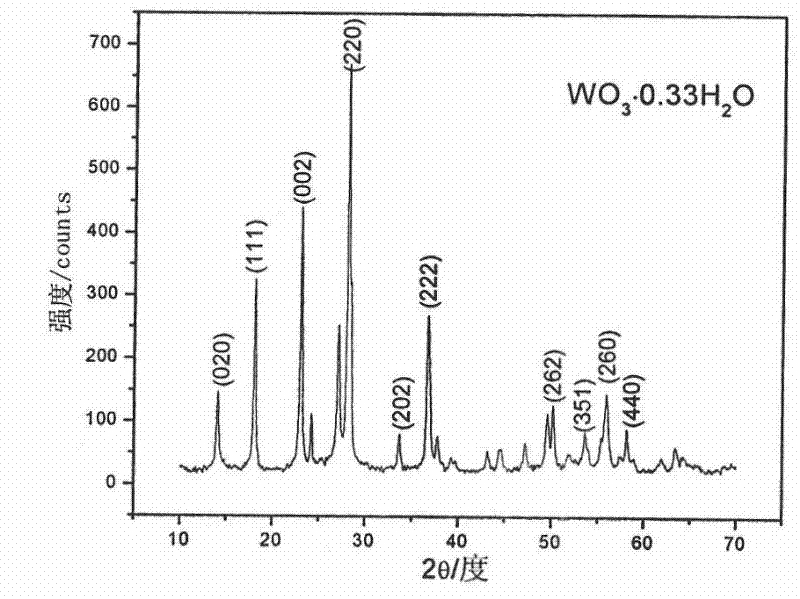

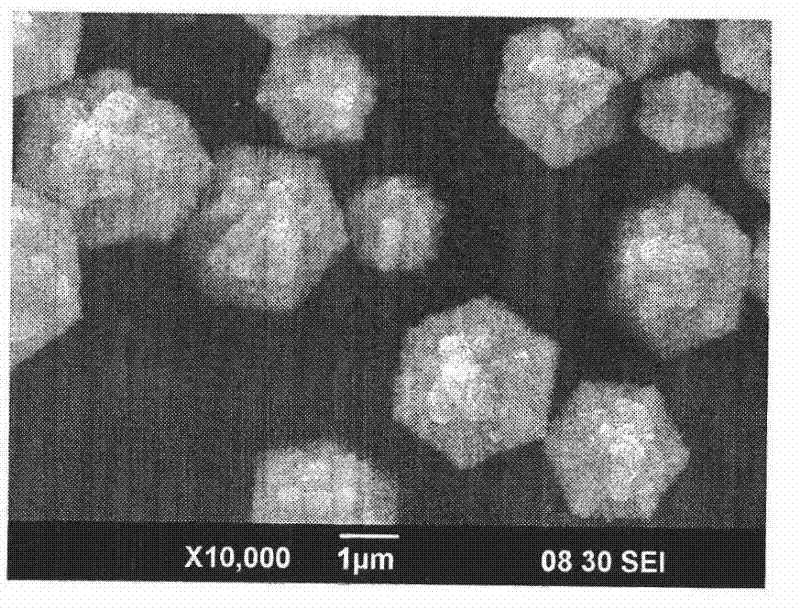

Preparation method of hexagon snow shaped WO3 nanometer disc

A snowflake-shaped and hexagonal technology, which is applied in the field of preparation of WO3 nanodiscs, can solve the problems of resource consumption or appearance, unsatisfactory crystal effect, and difficulty in precise control, and achieve short preparation cycle, uniform shape and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: 1) at first, add 20ml analytically pure hydrogen peroxide solution that volume fraction is 30% in the beaker, and beaker is placed in cold water bath, slowly, add 4g analytically pure, particle size is 200 Target tungsten powder, after the reaction is finished, collect the filtrate in the beaker and record it as solution A;

[0017] 2) Then, add deionized water to the A solution for dilution, so that W in the solution 6+ The concentration of is 0.1mol / L, obtains solution B;

[0018] 3) Pour the above-mentioned B solution into a microwave hydrothermal reaction kettle, and the filling degree is controlled at 60%; then seal the microwave hydrothermal reaction kettle, and put it into an MDS-8 type temperature-pressure dual-control microwave hydrothermal reaction apparatus; select The reaction was carried out in temperature control mode, the hydrothermal temperature was controlled at 180°C, the reaction time was controlled at 60 minutes, and naturally cooled t...

Embodiment 2

[0021] Embodiment 2: 1) at first, in beaker, add 20ml analytical pure hydrogen peroxide solution that the volume fraction is 30%, and beaker is placed in cold water bath, slowly, add 4g analytical pure, particle size is 200 Target tungsten powder, after the reaction is finished, collect the filtrate in the beaker and record it as solution A;

[0022] 2) Then, add deionized water to the A solution for dilution, so that W in the solution 6+ The concentration of is 0.1mol / L, obtains solution B;

[0023] 3) Pour the above-mentioned B solution into a microwave hydrothermal reaction kettle, and the filling degree is controlled at 60%; then seal the microwave hydrothermal reaction kettle, and put it into an MDS-8 type temperature-pressure dual-control microwave hydrothermal reaction apparatus; select The reaction is carried out in temperature control mode, the hydrothermal temperature is controlled at 140°C, the reaction time is controlled at 120min, and naturally cooled to room tem...

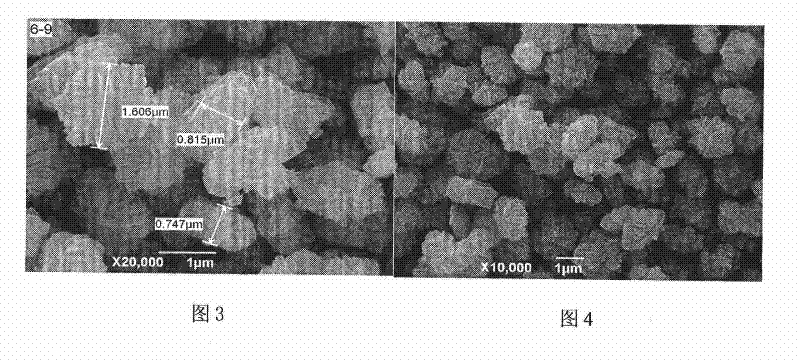

Embodiment 3

[0026] Embodiment 3: 1) at first, in beaker, add 20ml analytical pure hydrogen peroxide solution that the volume fraction is 30%, and beaker is placed in cold water bath, slowly, add 4g analytical pure, particle size is 200 Target tungsten powder, after the reaction is finished, collect the filtrate in the beaker and record it as solution A;

[0027] 2) Then, add deionized water to the A solution for dilution, so that W in the solution 6+ The concentration of is 0.03mol / L, obtains solution B;

[0028] 3) Pour the above B solution into the microwave hydrothermal reaction kettle, and the filling degree is controlled at 50%; then seal the microwave hydrothermal reaction kettle, and put it into the MDS-8 type temperature-pressure dual-control microwave hydrothermal reaction apparatus; select The reaction was carried out in temperature control mode, the hydrothermal temperature was controlled at 200°C, the reaction time was controlled at 20 minutes, and naturally cooled to room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com