Preparation method of humic acid organic fertilizer

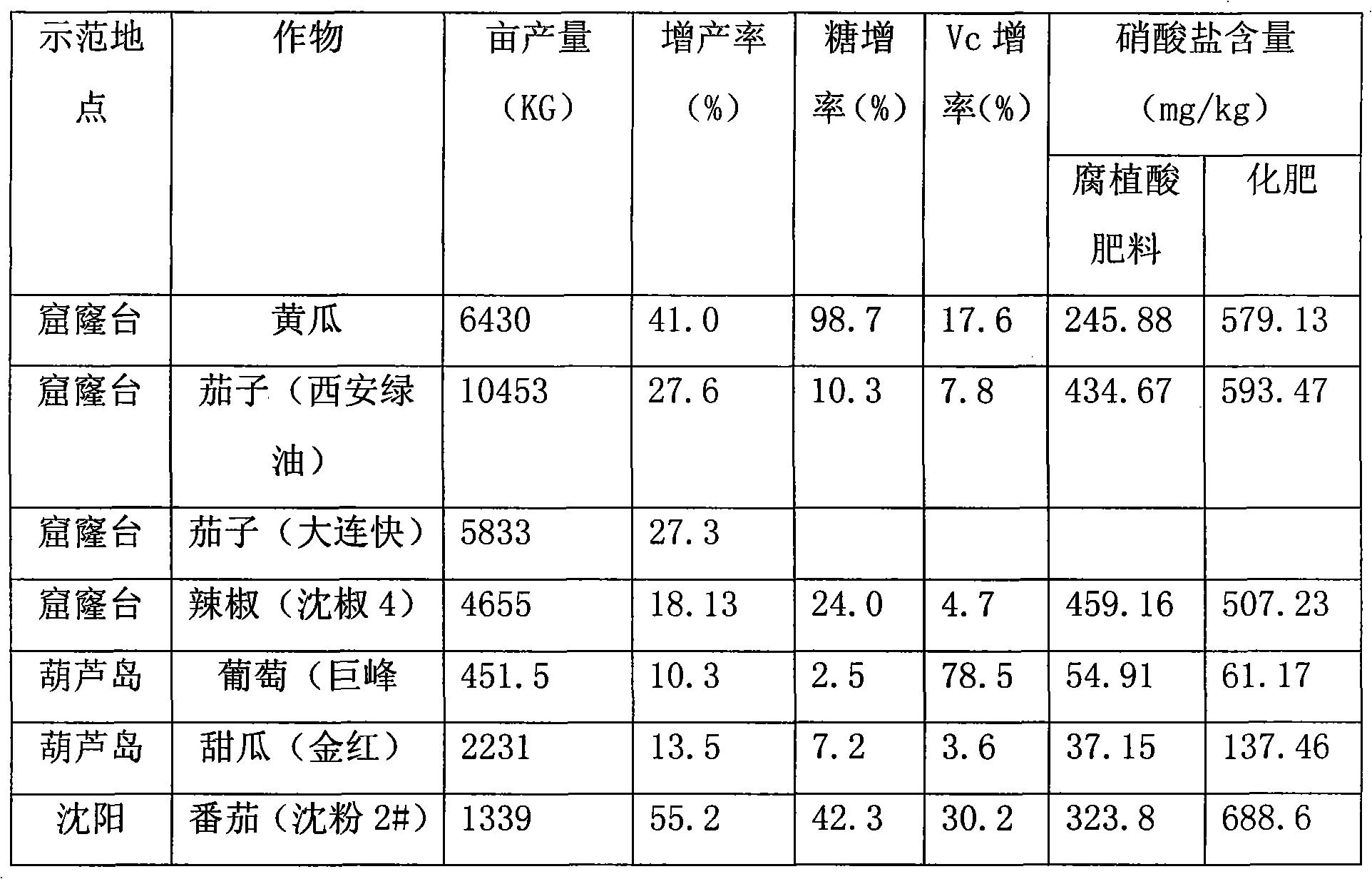

A humic acid and organic fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of high incidence of gastric cancer and esophageal cancer, poor crop quality, loss of soil fertility, etc., to extend the harvest period, improve water retention capacity, increase The effect of fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Prepare the raw material of humic acid organic fertilizer of the present invention, by mass percentage, mass concentration is 25% hydrogen peroxide (hydrogen peroxide solution) 5%, ammonium bicarbonate 15%, superphosphate 9%, potassium sulfate 0.7%, Sodium hydroxide 2.0%, potassium permanganate 0.8%, zinc sulfate 1.2%, borax 1.3%, ferrous sulfate 1.1%, activator (using sodium carbonate) 0.7%, and the balance is lignite.

[0049] The inventive method adopts common commercial lignite.

[0050] The method for preparing humic acid organic fertilizer of the present invention is as follows.

[0051] (1) Crushing and pulverizing the lignite so that the particle size reaches ≤0.2mm;

[0052] (2) Put pulverized lignite coal powder, sodium carbonate and hydrogen peroxide into the reaction kettle according to the ratio, vibrate with 20khz ultrasonic wave for 7 minutes, then heat to 135°C, and keep it warm for 17 minutes under the pressure of 0.5MPa to carry out cracking , Oxidat...

Embodiment 2

[0058] Prepare the raw material of humic acid organic fertilizer of the present invention, by mass percent, mass concentration is 30% hydrogen peroxide (hydrogen peroxide solution) 4%, ammonium bicarbonate 17%, superphosphate 10%, potassium sulfate 0.8%, Sodium hydroxide 2.2%, potassium permanganate 0.9%, zinc sulfate 1.4%, borax 1.5%, ferrous sulfate 1.3%, activator (using sodium carbonate) 0.8%, and the balance is lignite.

[0059] The inventive method adopts common commercial lignite.

[0060] The method for preparing humic acid organic fertilizer of the present invention is as follows.

[0061] (1) Crushing and pulverizing the lignite so that the particle size reaches ≤0.2mm;

[0062] (2) Put pulverized lignite coal powder, sodium carbonate and hydrogen peroxide into the reaction kettle according to the ratio, vibrate with 25khz ultrasonic wave for 3 minutes, then heat to 150°C, and keep it warm for 15 minutes under the pressure of 0.6MPa to carry out cracking , Oxidatio...

Embodiment 3

[0068] Prepare the raw material of humic acid organic fertilizer of the present invention, by mass percent, mass concentration is 20% hydrogen peroxide (hydrogen peroxide solution) 6%, ammonium bicarbonate 12%, superphosphate 8%, potassium sulfate 0.6%, Sodium hydroxide 1.7%, potassium permanganate 0.7%, zinc sulfate 1%, borax 1%, ferrous sulfate 0.9%, activator (using sodium carbonate) 0.5%, and the balance is lignite.

[0069] The inventive method adopts common commercial lignite.

[0070] The method for preparing humic acid organic fertilizer of the present invention is as follows.

[0071] (1) Crushing and pulverizing the lignite so that the particle size reaches ≤0.2mm;

[0072] (2) Put pulverized lignite coal powder, sodium carbonate and hydrogen peroxide into the reaction kettle according to the ratio, vibrate with 15khz ultrasonic wave for 10 minutes, then heat to 120°C, and keep it warm for 20 minutes under the pressure of 0.4MPa to carry out cracking , Oxidation re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com