Peristaltic solid state fermentation reactor for cellulose fermentation volatile alcohol and fermentation method thereof

A solid-state fermentation and reactor technology, applied in specific-purpose bioreactors/fermenters, solid-phase fermentation bioreactors, bioreactor/fermenter combinations, etc., can solve the problems of mass transfer, heat transfer, microbial Cell damage, damage to microbial cells and other problems, to achieve the effect of improving fermentation efficiency, reducing product inhibition, and solving fermentation microbial cell damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

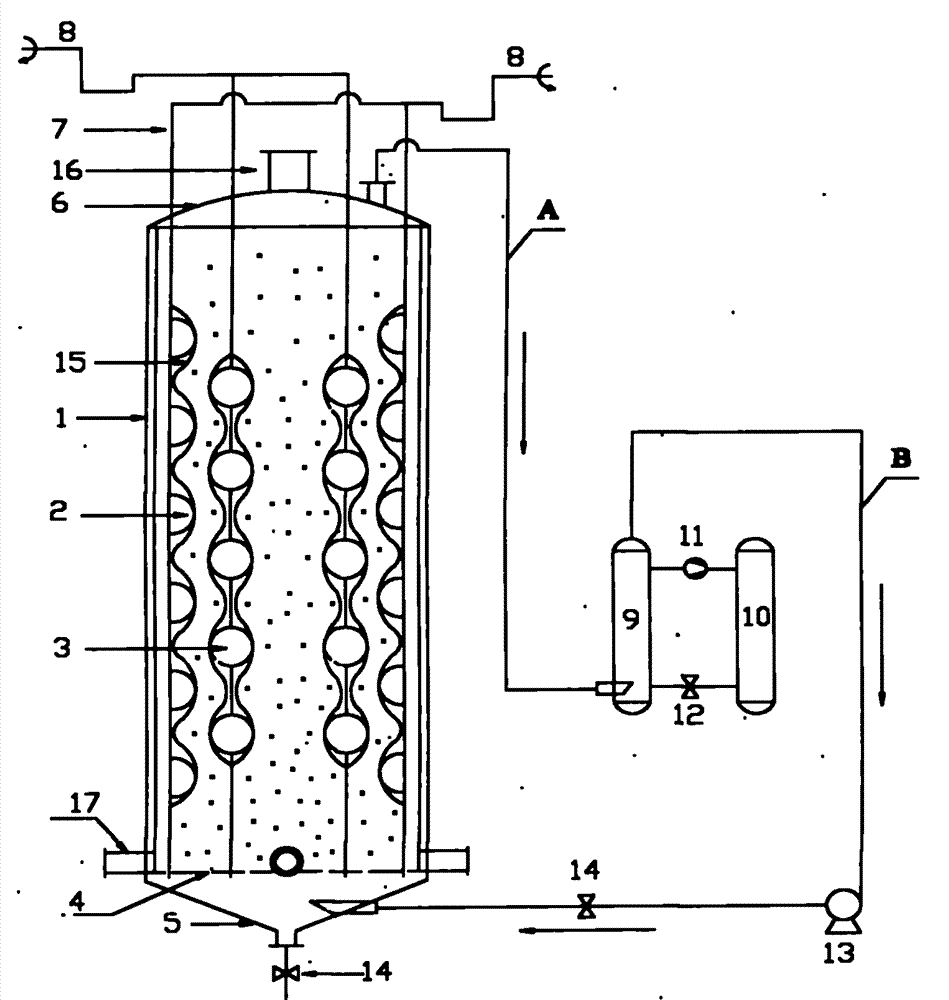

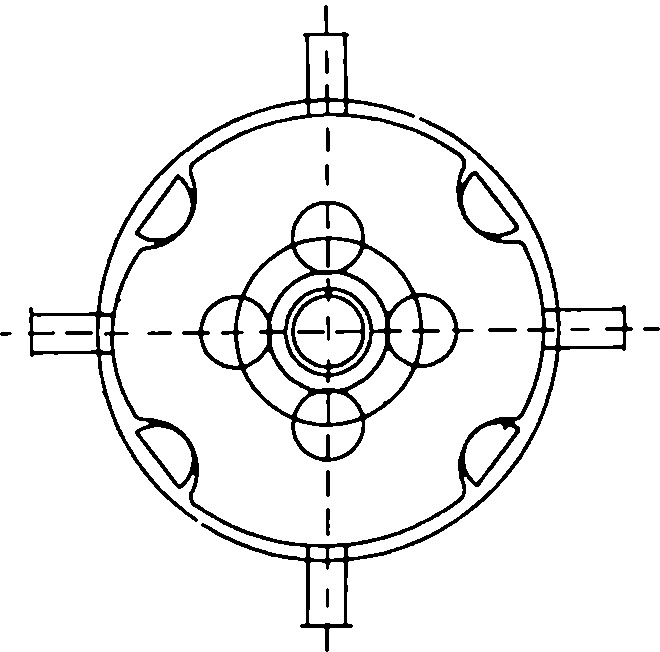

[0032] A peristaltic solid-state fermentation reactor for cellulose fermentation of volatile alcohol in this embodiment has an aspect ratio of 3, a total design volume of 50 L, and the up and down reciprocating motion of the shaft is realized by a motor combined with a crankshaft and connecting rod.

[0033] The fermentation operation steps are as follows: use crushed steam-exploded corn stalks with a water content of 50% and a cellulose content of 35% as raw materials, use 0.1Mpa high-pressure steam to sterilize, and use a cellulase dosage of 20IU filter paper enzyme activity / g pre-treated cellulose Raw material, cellulase is sterilized by 0.45μm ultrafiltration membrane, 40L of cellulose raw material and cellulase are added to the fermenter, inoculated with Angelica high activity dry yeast Saccharomyces cerevisiae (0.2% inoculum), and added nutrients (0.1% (NH 4 ) 2 SO 4 , 0.1% KH 2 PO 4 ), adjust the pH to 4.8-5.0, control the temperature in the fermentation tank at 35°...

Embodiment 2

[0035] This embodiment adopts the fermentation reactor of Embodiment 1, and its fermentation operation steps are as follows: use the pulverized steam-exploded corn stalks with a water content of 50% and a cellulose content of 35% as raw materials, use 0.1Mpa high-pressure steam to sterilize, and cellulase Amount of 20IU filter paper enzyme activity / g pretreatment cellulosic raw material, cellulase use 0.45 μ m ultrafiltration membrane filtration sterilization, 40L of cellulosic raw material and cellulase are added in the fermenter together, inoculate Clostridium acetobutylicum ( C.acetobutylicum AS1.132), inoculum size 10%, and added nutrients (0.2% (NH 4 ) 2 SO 4 , 0.2% yeast extract, 0.05% KH 2 PO 4 , 0.05%K 2 HPO 4 ), adjust the pH to 6.5-7.0, control the temperature in the fermenter at 37°C, turn on the motor on the shaft, make the shaft drive the ball to move up and down, push the solid material to move back and forth, and use CO 2 Replace the air in the system, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com