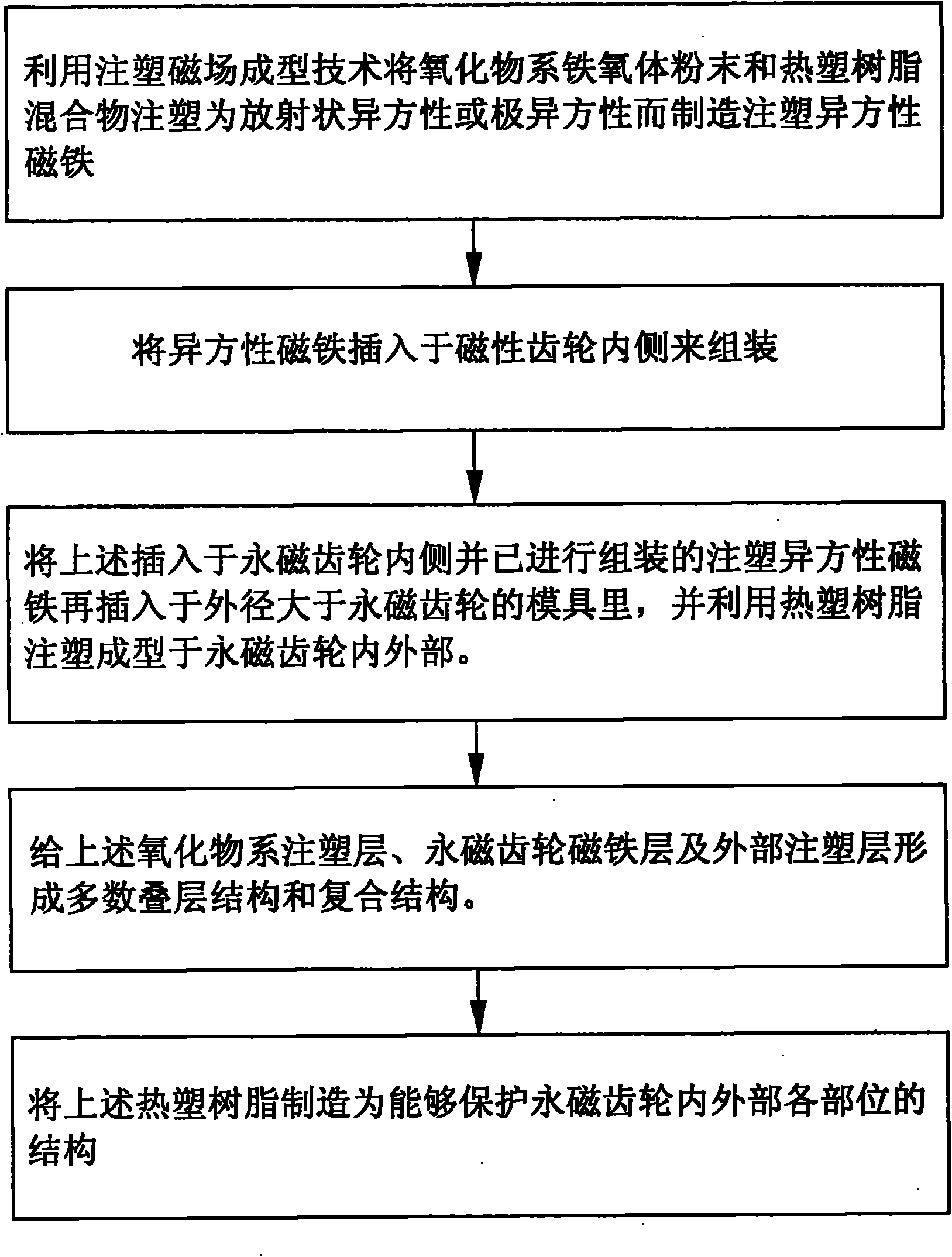

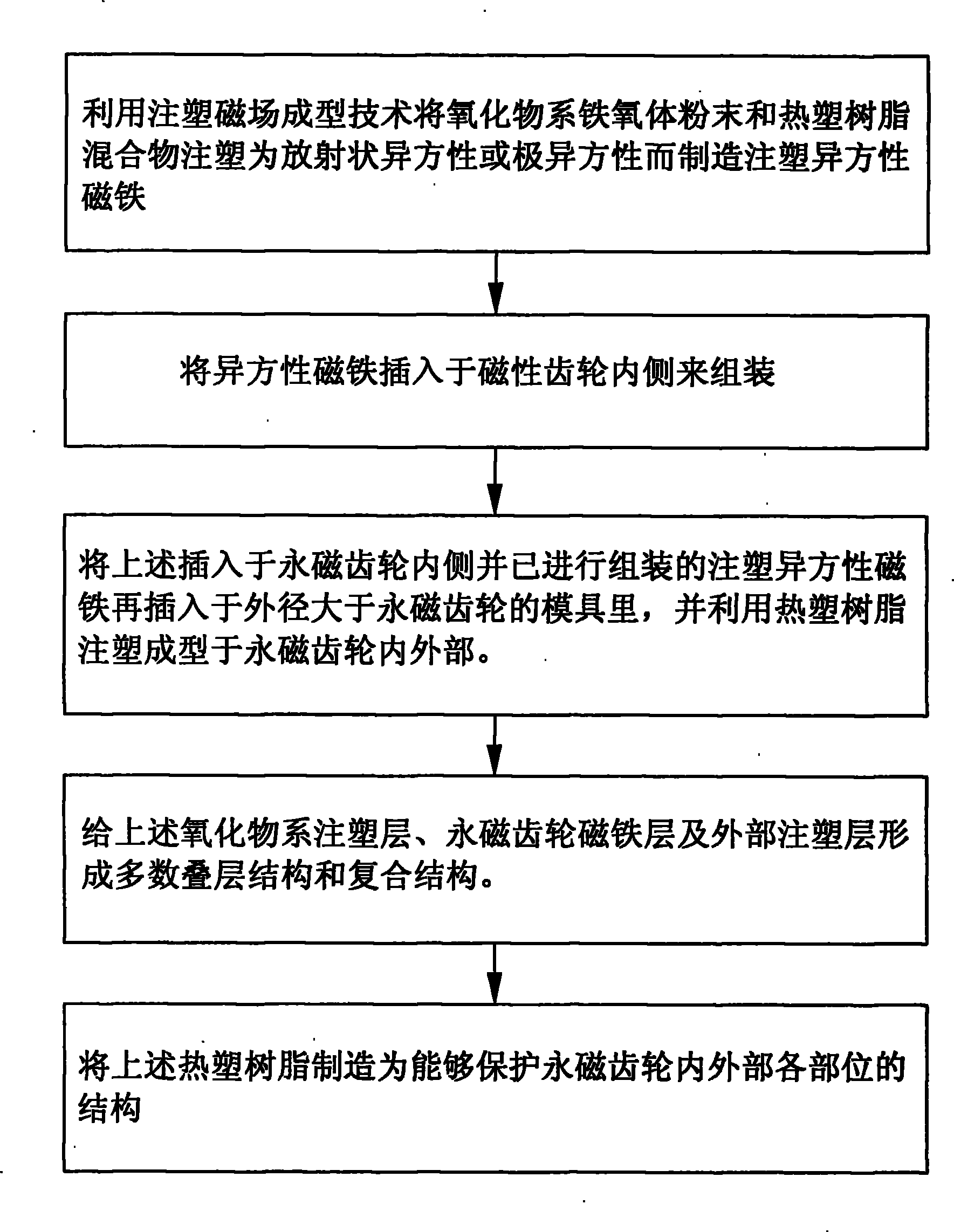

Manufacturing method of permanent magnetic gear

A manufacturing method and gear technology, applied in the manufacture of inductors/transformers/magnets, electrical components, pipes/pipe joints/pipe fittings, etc., can solve the problem of reduced reliability and it is difficult to apply to areas where the cleaning line is completely exposed to moisture. Low satisfaction and other issues, to achieve the effect of improving satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] According to the previous technology, its magnetism is 37HR grade (residual magnetic velocity density = 12.6kG, coercive force = 17kOe, maximum energy product = 37Moe) rare earth radial ring sintered magnet and JHNC157 grade (residual magnetic velocity density = 7kG, coercive force = 8kOe, maximum energy product = 9.5Moe) Each pair of rare earth equilateral bond magnets is coated with electrophoretic epoxy resin and coated on the surface, and then manufactured into a size of 39mmΦ x 32mmΦ x 26mm high. After assembling this with a non-magnetic POM Holder with an outer diameter of 32mmΦ x an inner diameter of 17mmΦ x a height of 30mm, it is magnetized with 10 poles and 45 degrees skew poles for use as permanent magnet gears. While rotating in the direction of the outer diameter of the magnet, the surface layer magnetic velocity density was measured with a Gauss meter and the results are shown in Table 1. The maximum surface magnetic velocity densities of the aforementione...

Embodiment 2

[0025] Sr-Ferrite powder (OP-71 manufactured by Nippon Bengara) and amine coupling agent A-1120 (manufactured by Unikar, Japan) were diluted with nucleic acid, etc., mixed uniformly with an attritor and dried to perform powder surface treatment. Add thermoplastic resin Nylon12 (ZZ3000P manufactured by Degussa) and fatty acid amide (manufactured by Huaxing Japan) that can improve fluidity to this powder, and use a 2-axis mixing air compressor to make small pellets at 210-260 ° C. Then, put the ball into the magnetic field injection mold, and under the injection molding conditions of mold temperature 80°C, injection temperature 220-270°C, and injection pressure 900-1500kg / cm2, the size of outer diameter 32mmΦ×inner diameter 17mmΦ×height 26mmt is produced. The 10-pole anisotropic resin magnet. Among the above-mentioned projects, the project of injection molding with extremely anisotropic magnetic field for each mixture is the most important project to implement isotropicization o...

Embodiment 3

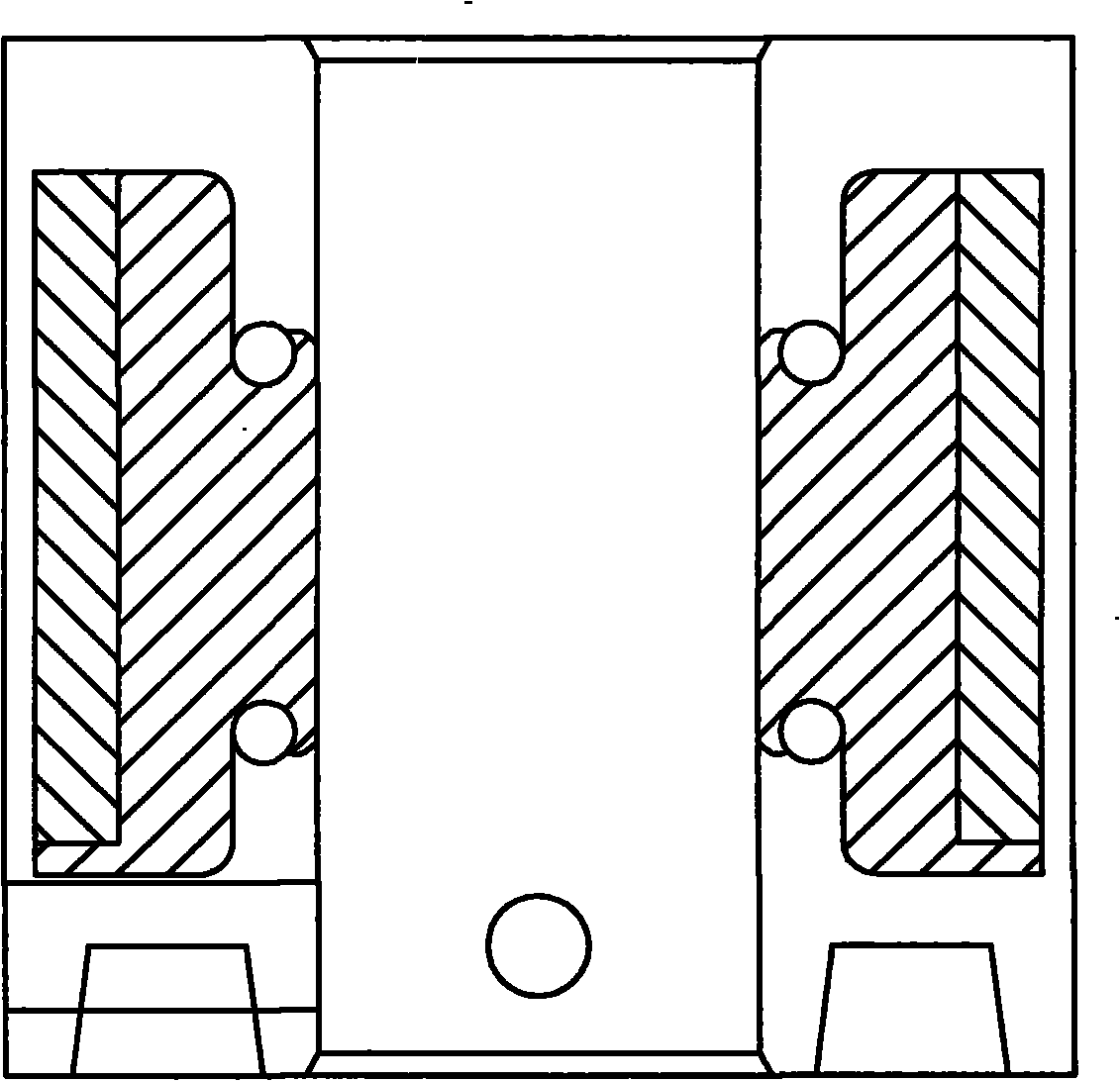

[0029]Using the same small pellets and magnetic field injection molding conditions as in Example 2 above, the first magnetic field injection molding was performed on a 10-pole 45-degree skew magnetization pole anisotropy mold with an outer diameter of 32mmΦ and an inner diameter of 17mmΦ to manufacture an outer diameter of 32mmΦ×inner diameter of 17mmΦ×height 26mmt ferrite pole anisotropic magnet. On this magnet, the outer diameter 39mmΦ×inner diameter 32mmΦ×high 26mm size 37HR rare earth Radial ring permanent magnet and JHNC157grade (residual magnetic velocity density (Br)=7kG, coercive force (Hc)=8kOe, Maximum magnetic energy product (Bhmax) = 9.5MOe) After each pair of rare earth isotropic Bond magnets, in order to maximize the surface magnetic velocity density of the permanent magnet gear, the magnets are assembled in the direction of mutual attraction. Put this again into an injection mold with an outer diameter of 40mmΦ×inner diameter of 17mmΦ×a height of 32mm, and perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com